Izidingo zokufakwa kanye nezinyathelo zokuphepha zamapayipi amanzi, izingxenye ze-hydraulic kanye nezingxenye ezisizayo kumasistimu we-hydraulic

2023-10-26Ukufakwa kwesistimu ye-hydraulic, okuhlanganisa ukufakwa kwamapayipi adonsa amanzi, izakhi zamanzi, izakhi ezisizayo, njll., empeleni kuwukuxhuma amayunithi noma izingxenye ezahlukahlukene zohlelo ngezixhumi eziwuketshezi (igama elijwayelekile lamapayipi kawoyela namajoyinti) noma ama-hydraulic manifolds. ukwakha isekethe. Lesi sihloko sabelana ngezidingo zokufakwa kanye nezinyathelo zokuphepha zamapayipi asebenza ngamanzi, izakhi ze-hydraulic, kanye nezingxenye ezisizayo kumasistimu asebenza ngamanzi.

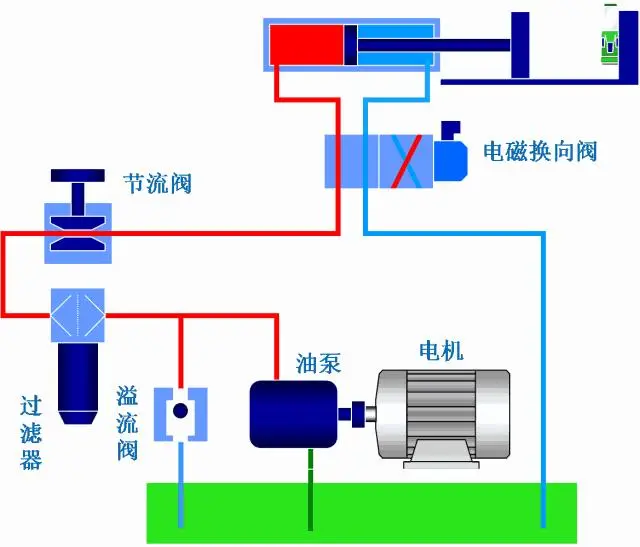

Ngokwefomu lokuxhuma lezingxenye zokulawula i-hydraulic, lingahlukaniswa libe: uhlobo oluhlanganisiwe (uhlobo lwesiteshi se-hydraulic); uhlobo lwe-decentralized. Womabili amafomu adinga ukuxhunywa ngokuxhuma uketshezi.

1.Ukufakwa kwezingxenye ze-hydraulic

Ukufakwa kanye nezidingo ezithile zezingxenye ezihlukahlukene ze-hydraulic. Izingxenye ze-hydraulic kufanele zihlanzwe ngophalafini ngesikhathi sokufakwa. Zonke izingxenye ze-hydraulic kumele zibe nengcindezi kanye nokuhlolwa kokusebenza kokuvala uphawu. Ngemva kokuphumelela ukuhlolwa, ukufakwa kungaqala. Amathuluzi okulawula okuzenzakalelayo ahlukahlukene kufanele alinganiswe ngaphambi kokufakwa ukuze kugwenywe izingozi ezidalwa ukungalungi.

Ukufakwa kwezingxenye ze-hydraulic ikakhulukazi kubhekisela ekufakweni kwama-valve amanzi, ama-hydraulic cylinders, amaphampu we-hydraulic kanye nezingxenye ezisizayo.

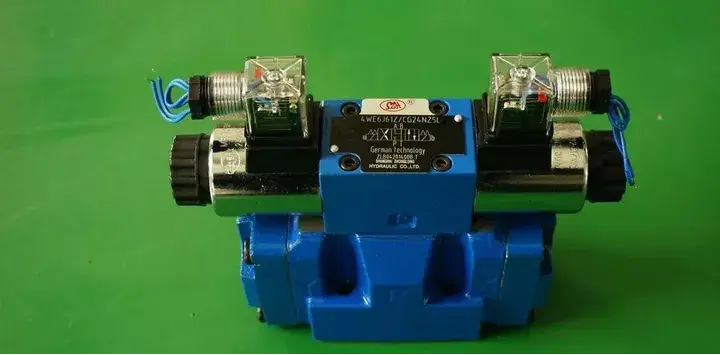

2. Ukufakwa kanye nezidingo zamavalvu angama-hydraulic

Ngaphambi kokufaka izakhi ze-hydraulic, izingxenye ze-hydraulic ezingapakishiwe kufanele ziqale zihlole isitifiketi sokuvumelana futhi zibuyekeze imiyalelo. Uma kuwumkhiqizo ofanelekayo onezinqubo eziphelele, futhi akuwona umkhiqizo ogcinwe endaweni evulekile isikhathi eside futhi ugqwalile ngaphakathi, akukho ukuhlolwa okwengeziwe okudingekayo futhi akunconywa. Ingahlakazwa futhi ihlanganiswe ngokuqondile ngemva kokuhlanza.

Uma kwenzeka ukungasebenzi kahle ngesikhathi sokuhlolwa, izingxenye kufanele zihlakazwe futhi ziphinde zihlanganiswe kuphela lapho ukwahlulela kunembile futhi kudingekile. Ikakhulukazi emikhiqizweni yangaphandle, ukuhlakazwa okungahleliwe nokuhlanganisa akuvunyelwe ukugwema ukuthikameza ukunemba komkhiqizo lapho uphuma efektri.

Naka okulandelayo lapho ufaka ama-hydraulic valves:

1) Lapho ufaka, naka indawo yokungena kawoyela kanye nechweba lokubuya lengxenye ngayinye ye-valve.

2) Uma indawo yokufaka ingacacisiwe, kufanele ifakwe endaweni elungele ukusetshenziswa nokugcinwa. Ngokuvamile, i-valve yokulawula isiqondiso kufanele ifakwe nge-axis evundlile. Lapho ufaka i-valve yokuhlehla, izikulufo ezine kufanele ziqiniswe ngokulinganayo, ngokuvamile ngamaqembu ama-diagonals futhi kancane kancane ziqiniswe.

3) Kuma-valve afakwe ngama-flange, izikulufu azikwazi ukuqiniswa kakhulu. Ukuqinisa ngokweqile ngezinye izikhathi kungase kubangele ukuvalwa kahle uphawu. Uma uphawu lwangempela noma impahla ingakwazi ukuhlangabezana nezidingo zokuvala, kufanele kushintshwe ifomu noma impahla yophawu.

I-4) Ukuze kube lula ukukhiqiza nokufakwa, amanye ama-valve ngokuvamile anezimbobo ezimbili ezinomsebenzi ofanayo, futhi ongasetshenzisiwe kufanele avinjwe ngemva kokufakwa.

5) Amavalvu adinga ukulungiswa ngokuvamile azungeza iwashi ukuze akhulise ukugeleza nokucindezela; zungezisa ngokuphambene newashi ukuze wehlise ukugeleza noma ingcindezi.

I-6) Ngesikhathi sokufakwa, uma amanye ama-valve kanye nezingxenye zokuxhuma zingatholakali, kuvunyelwe ukusebenzisa ama-valve we-hydraulic ngesilinganiso sokugeleza esidlula u-40% wokugeleza kwawo okulinganiselwe.

3. Ukufakwa kanye nezidingo ze-hydraulic cylinder

Ukufakwa kwe-hydraulic cylinder kumele kube okuthembekile. Akufanele kube nokuntenga ekuxhumekeni kwamapayipi, futhi indawo ekhuphukayo yesilinda nendawo eshelelayo yepiston kufanele igcine ukufana okwanele kanye ne-perpendicularity.

Naka lokhu okulandelayo lapho ufaka isilinda esisebenza nge-hydraulic:

1) Kusilinda esihambayo esinesisekelo sonyawo olugxilile, i-eksisi yayo emaphakathi kufanele igxile ne-eksisi yamandla okulayisha ukugwema ukubangela amandla asemaceleni, angabangela kalula ukuguga kwezimpawu kanye nokulimala kwepiston. Uma ufaka i-hydraulic cylinder yento ehambayo, gcina isilinda sihambisana nendawo yokuhamba kwento ehambayo endaweni yesitimela esiqondisayo.

2) Faka isikulufu se-gland sokuvala se-hydraulic cylinder block bese usiqinisa ukuze uqinisekise ukuthi i-piston iyanyakaza futhi intante ngesikhathi sokushaywa okugcwele ukuvimbela ithonya lokwanda okushisayo.

4. Ukufakwa kanye nezidingo zephampu ye-hydraulic

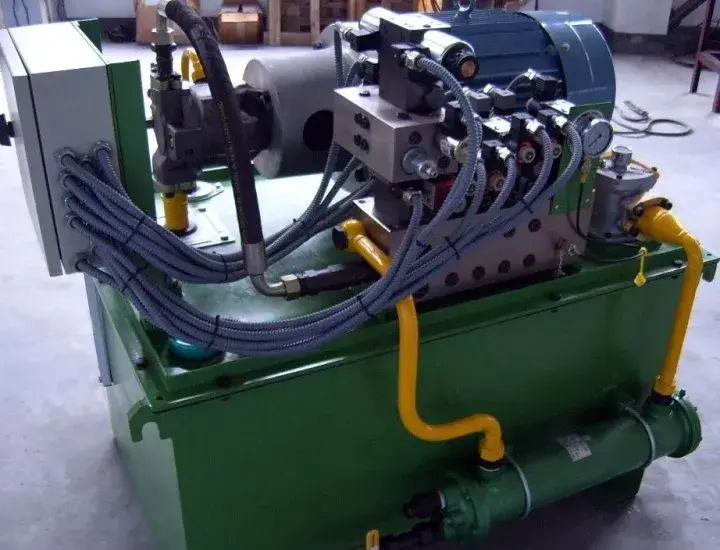

Lapho ipompo ye-hydraulic ihlelwa ethangini elihlukile, kunezindlela ezimbili zokufaka: enezingqimba futhi mpo. Ukufakwa okuqondile, amapayipi namaphampu kungaphakathi kwethangi, okwenza kube lula ukuqoqa ukuvuza kukawoyela futhi nokubukeka kucocekile. Ukufakwa okuvundlile, amapayipi avezwa ngaphandle, okwenza ukufakwa nokugcinwa kube lula.

Amaphampu e-hydraulic ngokuvamile awavunyelwe ukuthwala imithwalo ye-radial, ngakho-ke ama-motor kagesi avame ukusetshenziselwa ukushayela ngokuqondile ngama-couplings anwebekayo. Ngesikhathi sokufakwa, kuyadingeka ukuthi ama-shafts enjini kanye nepompo ye-hydraulic kufanele kube nokugxila okuphezulu, ukuchezuka kwawo kufanele kube ngaphansi kuka-0.1mm, futhi i-angle yokuthambekela akufanele ibe nkulu kuno-1 ° ukugwema ukwengeza umthwalo owengeziwe ku-shaft yepompo. futhi ebanga umsindo.

Uma ukuhanjiswa kwebhande noma igiya kudingekile, ipompo ye-hydraulic kufanele ivunyelwe ukususa imithwalo ye-radial ne-axial. Ama-hydraulic motors afana namaphampu. Amanye amamotho avunyelwe ukuthwala umthwalo othile we-radial noma i-axial, kodwa akufanele eqe inani elivumelekile elishiwo. Amanye amaphampu avumela ukuphakama okuphezulu kokumunca. Amanye amaphampu abeka ukuthi imbobo yokudonsa uwoyela kufanele ibe ngaphansi kwezinga likawoyela, kanti amanye amaphampu angenawo amandla okuzilungisa adinga iphampu eyisiza eyengeziwe ukuze anikeze uwoyela.

Naka lokhu okulandelayo lapho ufaka iphampu ye-hydraulic:

I-1) I-inlet, i-outlet kanye nesiqondiso sokuzungeza sepompo ye-hydraulic kufanele ihambisane nezidingo ezimakwe epompo, futhi akufanele ixhunywe ngokuhlehlayo.

I-2) Uma ufaka ukuhlanganisa, ungashayi i-pump shaft kanzima ukuze ugweme ukulimaza i-rotor yepompo.

5. Ukufakwa kanye nezidingo zezingxenye ezisizayo

Ngaphezu kokuxhumeka koketshezi, izingxenye ezisizayo zesistimu ye-hydraulic nazo zihlanganisa izihlungi, ama-accumulators, ama-coolers nama-heaters, amadivaysi okuvala, ama-gauge okucindezela, ukushintsha kwegeji yokucindezela, njll. Izingxenye ezisizayo zidlala indima eyisizayo ohlelweni lwe-hydraulic, kodwa azikwazi ukushaywa indiva. ngesikhathi sokufakwa, ngaphandle kwalokho zizothinta kakhulu ukusebenza okuvamile kwesistimu ye-hydraulic.

Naka okulandelayo lapho ufaka izingxenye ezisizayo:

1) Ukufakwa kufanele kwenziwe ngokuhambisana ngokuqinile nezidingo zokuklama futhi ukunaka kufanele kukhokhwe ubunono nobuhle.

2) Sebenzisa uphalafini ukuhlanza nokuhlola ngaphambi kokufakwa.

3) Lapho uhlangabezana nezidingo zokuklama, cabangela ukusetshenziswa kalula nokugcinwa kahle ngangokunokwenzeka.