Isakhiwo esiyisisekelo kanye nesimiso sokusebenza se-hydraulic system

2023-10-25一, Uhlolojikelele

Uhlelo lwe-hydraulic ikakhulukazi luhlanganisa iphampu kawoyela eyinhloko, ithangi le-hydraulic, isihlungi, i-valve yokunciphisa ingcindezi, i-valve yokusiza, isilinda sokuphakamisa, isilinda se-telescopic, isilinda se-tong, isilinda esiphuma ngaphandle, i-hydraulic motor, kanye nemisebenzi ehlukahlukene ye-hydraulic. ama-valve nezinye izingxenye. Ngaphambi kokuba imishini ihambe efektri, izingcindezi ze-valve yokusiza, i-valve yokunciphisa ingcindezi kanye nama-valve okucindezela ahlukahlukene ashintshiwe ukuze kuqinisekiswe ukusebenza okuphephile kwesistimu ye-hydraulic, futhi abasebenzisi abavunyelwe ukuwashintsha ngokuxhamazela ngesikhathi sokusetshenziswa.

I-hydraulic system ihlanganisa i-main hydraulic system kanye ne-steering hydraulic system, kanti lezi zinhlelo ezimbili zabelana ngethangi le-hydraulic.

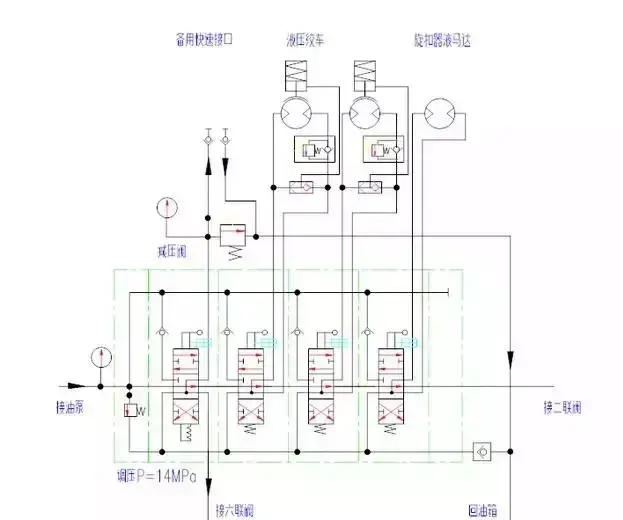

1.Isistimu ye-hydraulic eyinhloko

Uhlelo oluyinhloko lwe-hydraulic lunikeza amandla we-hydraulic ku-drilling rig ngesikhathi sokulungiswa kwemishini kanye nemisebenzi yokulungisa ukumba. Ifakwe ama-valve ahlukahlukene ukulawula ukusebenza okulungile nokuphephile kwethuluzi ngalinye le-hydraulic.

2.Stering Hydraulic System

I-steering hydraulic system ihlinzeka ngamandla e-hydraulic esiteringini samandla we-hydraulic we-axle yangaphambili yemoto. Ifakwe ama-valve ahlukahlukene ukulawula ingcindezi, isiqondiso sokugeleza kanye nokugeleza okuphezulu okuzinzile kwesistimu ye-hydraulic, ukuqinisekisa ukuthi ukuqondisa kwemoto kulula, kuyaguquguquka, kuphephile futhi kunokwethenjelwa.

3.Izici zesakhiwo

Uhlelo lwe-hydraulic luqukethe:

¨ Isistimu ye-hydraulic eyinhloko

¨ Isistimu ye-hydraulic steering

4.Isistimu ye-hydraulic eyinhloko

Liqukethe izinto ezilandelayo:

1) Ithangi likawoyela weHydraulic: izitolo, ukupholisa, ukushona phansi kanye nokuhlunga uwoyela we-hydraulic. Ithangi lamafutha lifakwe:

l Kunamakhava amabili emigodi efakwe phezulu ethangini likaphethiloli. Isihlungi somoya we-hydraulic sifakwa embozweni yomgodi endaweni yokubuyisela uwoyela ethangini likaphethiloli;

l Isihlungi somoya esine-hydraulic, sihlunga umoya ogeleza ethangini likaphethiloli, futhi sihlunge uwoyela lapho ithangi likaphethiloli ligcwaliswa;

l Izikali zamazinga oketshezi, 2, afakwe ngaphambili kwethangi likawoyela. Kunamageji ezinga le-liquid amabili, aphezulu naphansi. I-gauge yezinga eliphezulu lezinga le-liquid ibonisa izinga likawoyela ngemva kokwehliswa kwe-derrick; igeji yezinga le-liquid yezinga eliphansi ibonisa izinga likawoyela ngemva kokwakhiwa kwe-derrick;

l Igeji yokushisa kawoyela ifakwa ohlangothini olungaphambili lwethangi likaphethiloli ukukala izinga lokushisa likawoyela ethangini. Izinga lokushisa elivamile likawoyela osebenzayo liphakathi kuka-30 no-70°C. Kunamachweba amabili amakhulu okubuyisela uwoyela, abekwe epuletini elingezansi lethangi likaphethiloli. Afakwe ama-valve endlela eyodwa futhi axhunywe ngokulandelana. Ipayipi elikhulu lokubuyisela uwoyela kanye nembobo yokubuyisela i-valve yokusiza; i-valve yendlela eyodwa ivala ngokuzenzakalelayo lapho kulungiswa ipayipi le-hydraulic ukuvimbela ukulahleka kukawoyela ethangini;

l Imbobo yokudonsa amanzi isethwe epuletini elingezansi lethangi likaphethiloli futhi livinjwe ngepulaki; vula ipulaki ukukhipha uwoyela we-hydraulic tank;

l Imbobo yokudonsa yephampu kawoyela eyinhloko isethwe ohlangothini olungaphambili lwethangi likaphethiloli, futhi isihlungi esikhulu sokumunca sifakiwe;

l Imbobo yokudonsa uwoyela oqondisayo isethwe ohlangothini olungaphambili lwethangi likaphethiloli, futhi isihlungi sokumunca uwoyela oqondisayo sifakiwe;

l Imbobo yokubuyisela uwoyela yesistimu yokuqondisa ibekwe epuleti elingaphansi lethangi likaphethiloli futhi ifakwe i-valve yendlela eyodwa. I-valve yendlela eyodwa ivala ngokuzenzakalelayo lapho kulungiswa ipayipi le-hydraulic ukuvimbela ukulahleka kukawoyela ethangini;

2) Iphampu kawoyela weHydraulic: Isakhiwo segiya elilodwa, amayunithi ama-2, ngokulandelana afakwe emabhokisini okukhipha amandla okudluliselwa kwe-hydraulic, ashayelwa yisondo lepompo le-torque converter. Lapho injini iphenduka, ibhokisi lokususa amandla lingashayela iphampu kawoyela. Ibhokisi lokususa amandla lifakwe i-hydraulic clutch. Uma kudingeka isenzo se-hydraulic, isibambo se-"liquid pump clutch" sebhokisi lokulawula lomshini wokubhoboza singasethwa futhi simiswe endaweni yokuthi "ipompo likawoyela ngiyavala". Iphampu yamafutha I ihlanganiswe ukuze ikhiphe amafutha okucindezela okusebenzayo; isibambo sisethelwe ku- "oil pump II". "Vala" isikhundla, iphampu kawoyela II ixhunyiwe futhi ikhipha uwoyela wengcindezi yokusebenza;. Isibambo sisesimweni sokungathathi hlangothi, futhi womabili amaphampu kawoyela ayakhipha bese ayama.

I-3) I-valve yokukhulula: Isakhiwo esisebenza ngomshayeli, amasethi ama-2, ngokulandelana afakwe ekugcineni kwe-oil outlet yepompo eyinhloko kawoyela we-hydraulic. Lungisa ingcindezi yesistimu, uvimbele ukugcwala kwesistimu, futhi uvikele isistimu nokuphepha kwengxenye.

Isimiso sesakhiwo se-valve yokukhulula: Yakhiwe ngevalvu yokushayela kanye nevalve yama-slide eyinhloko. Ingxenye ye-valve yokushayela ihlanganisa umzimba we-valve, i-valve yesilayidi, isiphethu esilawula ukucindezela nezinye izingxenye. Kunembobo encane engu-a kuvalvu yesilayidi ye-valve eyinhloko, ukuze amafutha okucindezela angenisiwe akwazi ukungena ekamelweni eliphezulu B levalvu yesilayidi. Uma i-hydraulic pressure esebenza ku-poppet valvu ingaphansi kwamandla okuqinisa ngaphambili entwasahlobo, i-valve ye-poppet valve yomshayeli izosebenza ngaphansi kwesenzo samandla asentwasahlobo. Njengoba kungekho ukugeleza kwamafutha emzimbeni we-valve, ingcindezi ye-hydraulic emakamelweni kawoyela emaphethelweni aphezulu naphansi we-valve yesilayidi iyalingana. Ngakho-ke, i-valve yesilayidi isesimweni esidlulele somkhawulo ophansi ngaphansi kwesenzo sentwasahlobo yokuphela ephezulu. I-inlet kanye ne-outlet ye-valve yokusiza inqunywe yi-valve yesilayidi, futhi i-valve yokusiza ayichichima; lapho umfutho we-hydraulic osebenza ku-valve ye-poppet ukhuphuka ulingana namandla entwasahlobo ngenxa yokwanda kokucindezela kokungena kwe-valve yokukhulula, i-valve ye-poppet iphushwa Ivule, amafutha egumbini eliphezulu B le-valve yesilayidi agelezela emafutheni. ukuphuma kwevalvu ngembobo yokubuyisela uwoyela b kanye nendawo emaphakathi ngembobo ye-slide valve, bese ichichima ibuyele ethangini likawoyela. Ngalesi sikhathi, uwoyela ocindezelayo endaweni yokungena kawoyela yevalvu yokukhulula ugeleza usuka embotsheni encane a. Ibuye igcwaliswe phezulu iye ku-chamber B. Ngenxa yokuthi kukhona ukwehla kwengcindezi lapho amafutha edlula embotsheni encane u-a, umfutho osegunjini B uphansi kunokucindezela endaweni yokungena kawoyela, futhi umehluko wengcindezi uvela phakathi kweziphetho ezingenhla nezingezansi. wevalve yesilayidi. Ngakho-ke, ngaphansi kwesenzo somehluko wengcindezi phakathi kweziphetho ezingenhla nezingezansi, i-valve yesilayidi inqoba amandla asentwasahlobo, futhi isisindo sevalve yesilayidi ngokwayo kanye nokungqubuzana kuya phezulu, kuvula imbobo yokungena neyokubuyisela yevalvu yokukhulula, futhi uwoyela uyageleza. ngibuyele ethangini. Ngemva kokuvulwa kwe-valve yesilayidi, uketshezi luqhutshwa amandla asebenza ngamanzi. Ithintekile, ukucindezela kwe-inlet P kuzoqhubeka nokukhuphuka, futhi i-valve yesilayidi izoqhubeka nokuya phezulu. Lapho amandla e-valve yesilayidi elingana endaweni ethile, ukucindezela kokungena kwe-valve yokusiza kuzozinza ngenani elithile, elibizwa ngokuthi ukucindezela kokumisa kwe-valve yokukhulula.

4) Isihlungi sokumunca uwoyela: Isakhiwo esizivalayo ngaphandle kwethangi, esifakwe eceleni kwethangi likawoyela we-hydraulic, ishubhu lokumunca uwoyela licwiliswa ngaphansi kwezinga eliwuketshezi ethangini likawoyela, futhi inhloko yesihlungi ivezwa ngaphandle ithangi likawoyela; ifakwe i-valve yokuzivala, i-valve yokudlula, Isici sokuhlunga singcolisa isidlulisi namanye amadivaysi. Lapho ushintsha noma uhlanza isici sokuhlunga, singahlakazwa futhi sifakwe ngaphandle kwethangi. Ngemva kokukhishwa kwesici sokuhlunga, ivalve yokuzivala ngokwayo ivaleka ukuze uwoyela ungaphumi ethangini. I-bypass valve, lapho isici sokuhlunga sivalekile, umshini akufanele uvalwe ngokushesha ukuze ulungiswe. Amafutha angasakazwa nge-valve ye-bypass, futhi umshini ungavalwa ukuze uhlanze noma ushintshe into yokuhlunga ngesikhathi esifanele. Isikhombi somehluko wengcindezi siyisakhiwo sokuhlola esibonakalayo esisebenza ngomshini. Uma isici sokuhlunga sivalekile, sizothinta umehluko wengcindezi kawoyela futhi isikhombisi sizoshwibeka. , uma ikhomba indawo ebomvu, umshini kufanele uvaliwe ukuze kuhlanzwe noma kushintshwe isici sokuhlunga. I-valve yebhola ifakwa lapho kuphuma khona isisefo ukuze ivalwe ngesikhathi sokulungiswa kanye nokulungiswa kwepayipi elisebenza ngamanzi ukuze kunqandwe ukulahlekelwa uwoyela ethangini.

I-5) Isihlungi sikawoyela wokubuyisela: Ifakwe i-valve yokudlula kanye nenkomba yomehluko wengcindezi. Isihlungi sihluza ukungcola okuqinile kuwoyela we-hydraulic, sinqande ukungcola okusepayipini ukuthi kungangeni ethangini, futhi sigcina uwoyela wesistimu uhlanzekile; i-valve yokudlula isetshenziswa lapho isici sokuhlunga sivalekile. Ngemuva kwalokho, akuvunyelwe ukuvala umshini ngokushesha ukuze ulungiswe. Amafutha angasakazwa nge-valve ye-bypass, futhi umshini kufanele uvalwe ukuze uhlanze noma ubuyisele isici sokuhlunga ngesikhathi esifanele. Isikhombi somehluko wengcindezi siyisakhiwo sokuhlola okubonwayo ngomshini. Uma isici sokuhlunga sivalekile, esithinta umehluko wengcindezi kawoyela, inqwaba yenkomba iyelula futhi ikhomba indawo ebomvu. Uma kunesidingo, umshini kufanele uvalwe ukuze kuhlanzwe noma kushintshwe into yokuhlunga.

7) Ukuphakamisa uwoyela isilinda: isigaba sesithathu esiyinhlanganisela isilinda uwoyela isakhiwo, ifakwe one-way throttle valve; ukuphakamisa nokumisa i-derrick, i-valve yendlela eyodwa yokuvikela ukuvikela amandla adonsela phansi ngesikhathi senqubo yokufika kwe-derrick, nokuvikela ukuphepha kokuphakanyiswa nokuhlalisa kwe-derrick. Lo mshini ufakwe amasilinda aphakamisa kabili.

l Isakhiwo kanye nomgomo wokusebenza: Isakhiwo siqukethe isilinda, ipiston yezinga lokuqala, ipiston yezinga lesibili, ipiston yezinga lesithathu, indandatho yomhlahlandlela, indandatho yokuvala nezinye izingxenye. Ikhanda lesilinda lifakwe i-pin ear plate, exhunywe epuleti lendlebe elingashintshi ku-frame cross cross ngophini. I-piston rod yesiteji sesithathu ixhunywe kuphini lozimele lomnyango we-derrick ophansi ngendlela efanayo. Ama-plungers ezinga lokuqala nelesibili anesakhiwo sesenzo sendlela eyodwa. Ngaphansi kwesenzo sikawoyela we-hydraulic, i-plunger inweba ngamandla futhi ihoxise ngesisindo sayo uma ibuya. Ipiston yezinga lesithathu inesakhiwo sesenzo sezindlela ezimbili. Ngaphansi kwesenzo sikawoyela we-hydraulic, i-piston yezinga lesithathu inika amandla isandiso nokuhoxiswa. Isilinda esiphakamisayo sifakwe izimbobo zikawoyela ezintathu, i-P1, i-P2 ne-P3. Imbobo kawoyela i-P1 itholakala ekhanda le-cylinder, elixhuma igumbi lokusebenza le-plunger kanye negumbi le-piston lesiteji sesithathu elingenazintambo. Kukhona i-valve ye-throttle yendlela eyodwa endaweni yamafutha; I-oil port P2 itholakala endaweni yesithathu ye-piston rod, exhuma igumbi le-piston lesiteji sesithathu le-rodless. Kukhona imbobo ye-throttle emgodini wenduku kanye nephaseji likawoyela; imbobo kawoyela i-P3 itholakala esiteji sesithathu se-piston rod, exhuma igumbi lokusebenza le-plunger kanye nesiteji sesithathu sesiteji se-piston rodless, futhi ixhunywe ne-P1 kawoyela iphaseji. Kukhona i-throttle hole ephaseji likawoyela. Imbobo yokukhipha umoya inikezwa esihlokweni sesilinda se-piston yesigaba sesithathu sesilinda samafutha, futhi ipulaki yokukhipha umoya ifakiwe kuyo.

l Ukukhipha Umoya: Ngaphambi kokuphakanyiswa kanye nokuhlaliswa ngakunye kwe-derrick, umoya osesilindani sokuphakamisa kanye nesilinda esibona kude kufanele ukhululwe ngokuphelele. Uwoyela weHydraulic unomoya, futhi ukuvuza epayipini kubangela umoya kusilinda. Lapho isilinda esiphakamisayo nesilinda se-telescopic kumiswe isikhathi eside, umoya uzonqwabelana engxenyeni engenhla yesilinda. Lapho i-derrick iphakanyiswa futhi yehliswa, amathuba ezingozi azokwanda, umoya uzokhishwa, futhi izingozi ezifihliwe zezingozi zizoqedwa.

l Ukukhishwa komoya kwepayipi lesistimu: Vula i-valve yenaliti engu-E kuphaneli yokulawula yamavalvu ahlangene ayisithupha ukuze wenze isekethe ebushelelezi yamasilinda aphakamisayo i-P1 ne-P3, bese uxhuma ipayipi lokubuyisela uwoyela. Phakamisa isibambo sevalvu yokulawula isilinda, uwoyela we-hydraulic wepompo kawoyela ungena kusilinda esiphakamisayo nge-P1, bese ubuyela ethangini likawoyela nge-P3. Uhlelo lwe-hydraulic lusebenza ngaphandle komthwalo; i-hydraulic system isebenza ngaphandle komthwalo imizuzu emi-5 kuya kweyi-10, isuse ukuvuza epayipini kanye negesi yesilinda esiphakamisayo.

l Khipha umoya emgodini wenduku yepiston yesigaba sesithathu sesilinda esiphakamisayo: vala i-valve yenaliti E, futhi amasilinda okuphakamisa i-P1 ne-P3 enza isifunda esivaliwe. Phakamisa kancane isibambo se-valve yokulawula isilinda, unikeze uwoyela ocindezelayo egumbini eliphansi lesilinda eliphakamisayo, lawula ukucindezela kukawoyela ku-2 ~ 3MPa, vula ipulaki elopha esihlokweni se-cylinder sesigaba sesithathu se-cylinder, bese ukhipha. umoya ku-cylinder ephakamisa.

l Ukuhlolwa kokuvuza kwesistimu: Phakamisa kancane i-valve yokulawula isilinda, unikeze uwoyela wokucindezela ekamelweni eliphansi lesilinda eliphakamisayo, phakamisa kancane i-derrick, shiya i-100 ~ 200mm kude kubakaki bangaphambili be-derrick, yeka ukuphakamisa, futhi ugcine i-derrick. esimweni imizuzu emi-5. Hlola uhlelo lwama-hydraulic namapayipi, akufanele kube khona ukuvuza noma kuphi; bheka i-derrick, akufanele kube khona okusobala ukuthi ukuphi.

l Indlela yokuphepha: I-derrick iyasinda, futhi maningi amathuba ezingozi lapho uphakamisa futhi wehlisa i-derrick. Naka kakhulu ngesikhathi sokusebenza futhi ulandele ngokuqinile izinqubo zokusebenza. Izindlela zokuphepha eziningi zisethelwe isilinda sokuphakamisa okuphephile. Ngisho noma i-valve yokulawula i-cylinder ephakamisa ihluleka noma i-hose ye-hydraulic iphukile futhi yonakele, isilinda esiphakamisayo sizonciphisa ngokuphumelelayo isivinini sokwehlisa i-derrick futhi sivimbele izingozi ezinkulu.

l Ukuphakamisa i-derrick: Uwoyela we-hydraulic ungena ekamelweni lokusebenza le-cylinder kawoyela esuka echwebeni le-P1 ngokusebenzisa i-valve yendlela eyodwa. I-plunger yezinga lokuqala inweba kuqala. Ngemva kokufinyelela endaweni, i-plunger yezinga lesibili kanye nenduku yepiston yezinga lesithathu zinwebeka ngokulandelana. Ipiston yezinga lesithathu inenduku. Amafutha asemgodini abuya nge-P2. Njengoba ichweba le-P2 lifakwe imbobo yokudonsa, lapho i-piston yesiteji sesithathu inweba, ukuvulwa kwe-valve yokulawula kufanele kuncishiswe futhi isivinini sokunwetshwa kufanele sincishiswe. Uma kungenjalo, ukucindezela kwesistimu ye-hydraulic kuzokwanda;

l Yehlisa i-derrick: Uwoyela we-hydraulic ungena emgodini wepiston yesiteji sesithathu ukusuka ku-P2, ephusha i-piston ukuze ihoxise. Amafutha emgodini ongenazintambo abuyela emafutheni ngokusebenzisa i-P1 throttle, futhi isilinda sihlehla kancane ukuvimbela amandla adonsela phansi; Ukuhlehlisa ukulandelana kwe-plunger ngayinye ne-piston ithi: okokuqala, i-piston yesiteji sesithathu iyahoxiswa. Ngemva kokufika kulesi sikhundla, ama-plungers esiteji sesibili kanye nesigaba sokuqala ahlehla ngokulandelana. Lapho ama-plunger esibili kanye ne-primary ehlehla, ahlehla ngesisindo sawo ngaphandle kokunikeza uwoyela we-hydraulic kusilinda. Ngalesi sikhathi, isivinini senjini singancishiswa futhi isibambo sokusebenza sibuyela kancane kancane ku-derrick.

8) I-Telescopic cylinder, i-hydraulic telescopic enezitezi ezimbili iderrick.

l Ukwakheka kwesakhiwo: Isilinda ende ye-plunger, enobude obuphelele obuyi-14 ukuya ku-16m. Kukhona imbobo yamafutha ekugcineni kwe-plunger, futhi i-valve ye-throttle yendlela eyodwa ifakwe emgudwini wamafutha; ikhanda lesilinda lifakwe ipulaki yokopha. Umzimba wesilinda samafutha uboshelwe emzimbeni ongaphezulu we-derrick ngamabhawodi amise okuka-U, futhi ingaphezulu licindezelwa eringini yesihlalo se-derrick beam. Ingxenye engezansi ye-plunger rod ifakwe ipuleti lokuxhuma, eliboshelwe emgodleni womzimba ophansi we-derrick.

l Inqubo yokusebenza. I-derrick esitezi sesibili inwetshiwe, futhi i-valve yokulawula yesilinda sikawoyela we-telescopic isetshenziswa ukuze iphakame. Amafutha okucindezela angena kusilinda ngembobo kawoyela ekugcineni kwe-plunger rod, i-valve yendlela eyodwa, kanye ne-hollow plunger, esunduza isilinda ukuze inwebe, eshayela umzimba ongaphezulu we-derrick ukuthi ukhuphuke eduze kwethrekhi. I-derrick isendaweni futhi indlela yephini lokukhiya ikhiywa ngokuzenzakalelayo. I-derrick yesitezi sesibili ihoxisiwe, futhi iphinikhodi yokuphepha ikhishwa mathupha. Okokuqala, ivalvu yokulawula isilinda ye-telescopic isetshenziselwe ukuphakamisa phezulu, ukuze i-derrick yesitezi sesibili ikhuphuke kancane cishe ngo-200mm. Iphinikhodi yokukhiya iyazivula ngokuzenzakalelayo, bese ivalvu yokulawula isilinda ye-telescopic isetshenziselwe ukusunduza phansi, futhi uwoyela we-hydraulic kusilinda Ukucindezela okukhiqizwa ukuzisinda kwe-derrick yesitezi sesibili kugeleza ku-cylinder ngokusebenzisa i-throttle. ichweba kanye nembobo kawoyela ekugcineni kwe-plunger. I-derrick yesitezi sesibili iyawa. Isivinini esiwayo silungiswa yi-degree yokuvula ye-valve yendlela eyodwa kanye nevalvu yokulawula isilinda ye-telescopic.

l Indlela yokuphepha: I-derrick esitezi sesibili inzima kakhulu, futhi maningi amathuba ezingozi lapho uphakamisa futhi wehlisa i-derrick. Naka kakhulu ngesikhathi sokusebenza futhi ulandele ngokuqinile izinqubo zokusebenza. Isilinda se-telescopic sokuphepha sifakwe i-valve yendlela eyodwa. Ngisho noma i-valve yokulawula isilinda ihluleka noma ipayipi elisebenza ngamanzi lidabukile futhi lilimele, isilinda sizonciphisa isivinini sokwehla kwe-derrick futhi sivimbele izingozi ezinkulu.

l I-Exhaust Air: Ngemva kokuba isilinda sibekwe isikhathi esithile, umoya uzongena usuka esigxivizweni. Isilinda esisanda kufakwa sinomoya omningi ngaphakathi. Ngakho-ke, ngaphambi kokusebenza ngakunye kwesilinda se-telescopic, umoya osesilinda se-telescopic kufanele ukhululwe ukuze kuvinjelwe inqubo yokwandisa yesilinda. Ukukhasa. Phakamisa kancane isibambo se-valve yokulawula isilinda, unikeze uwoyela wokucindezela kusilinda se-telescopic, futhi ulawule ukucindezela kukawoyela ku-2 kuya ku-3 MPa. Vula ipulaki ye-vent phezulu kwesilinda ukuze ukhiphe umoya kusilinda se-telescopic. Ngemva kokukhipha amanzi, qinisa i-nati. Unganyakazi ngenkathi uhlanza. Vula i-latch yokuphepha ye-derrick.

9) Isilinda Sokubamba: Isilinda sinesakhiwo sepiston esinezinhlangothi ezimbili, futhi izisetshenziswa ze-buffer zihlinzekwa kuzo zombili iziphetho zekhanda le-cylinder kanye nekhava ye-cylinder ukuvimbela umthelela we-hydraulic we-cylinder. Lapho induku ye-piston yesilinda samafutha ihlehla, intambo yekhanda lekati ye-tong yokuphakamisa iyaqiniswa ukuze iqinise futhi ixegise intambo yokubhoboza; induku yepiston iyanwebeka futhi intambo yekhanda lekati iyabuya.

I-10) I-Winch encane ye-Hydraulic: indlela yokunciphisa iplanethi, ifakwe i-valve yebhuleki nebhalansi, iphephile ukuphakamisa izinto futhi ingahamba emoyeni.

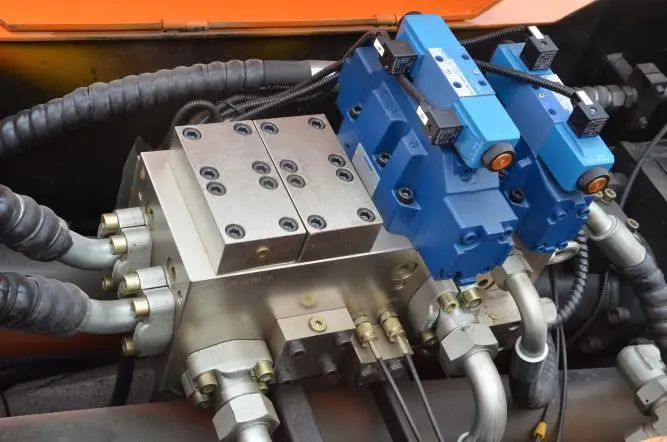

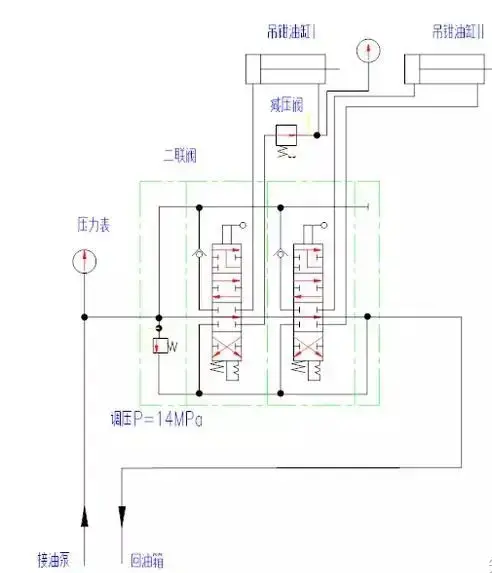

11) I-valve ephindwe kabili: Ifakwe engxenyeni engezansi yebhokisi lokulawula lomshini wokubhoboza, iqukethe ipuleti levalvu yokufaka uwoyela, ipuleti levalvu yokubuyisela uwoyela kanye namapuleti amavalvu amabili asebenzayo. Ucezu lwe-valve yokungena kawoyela lufakwe i-valve yokuphepha ukulungisa ingcindezi yokusebenza engena ku-valve ephindwe kabili. Khulula futhi uqinise inathi, bese usonta isikulufu sokulungisa ukuze ushintshe ukucindezela kokulungisa kwevalvu yokuphepha. Lapho i-screw in, ingcindezi yokulungisa iyanda, futhi lapho i-screw out, ingcindezi yokulungisa iyancipha. Qaphela ukuthi ngemva kokulungiswa, qinisa ikepisi elingemuva bese ukhiya nati elilungisayo. Ipuleti le-valve elisebenzayo lilawulwa ngesandla.

A. Ivalve yesilinda ye-tong I: Ilawula isilinda sokuphakamisa ithong I ukuze inwebe futhi ihlehle ukuze ixegise futhi iqinise intambo yekhanda lehange. I-valve core isethwe ngokuma kwe-valve entantayo ukuze yakhe isekethe yesilinda esihlukile. Amafutha epompo yamafutha kanye namafutha omgodi wenduku angena emgodini ongenazintambo we-cylinder yamafutha ngesikhathi esifanayo, okwenza ukuba induku ye-piston ikhule ngokushesha; i-valve core spring ibuya, ikhulule isibambo, futhi i-valve core ibuyela ngokuzenzakalelayo Esikhundleni sokungathathi hlangothi, ukunyakaza kwesilinda kuyama.

B. Ivalve ye-tong yesilinda II: Ilawula isilinda sokuphakamisa ithong II ukuze inwebe futhi ihlehle ukuze ixegise futhi iqinise intambo yekhanda lehange. I-valve core isethwe ngokuma kwe-valve entantayo ukuze yakhe isekethe yesilinda esihlukile. Amafutha epompo yamafutha kanye namafutha omgodi wenduku angena emgodini ongenazintambo we-cylinder yamafutha ngesikhathi esifanayo, okwenza ukuba induku ye-piston ikhule ngokushesha; i-valve core spring ibuya, ikhulule isibambo, futhi i-valve core ibuyela ngokuzenzakalelayo Esikhundleni sokungathathi hlangothi, ukunyakaza kwesilinda kuyama.

7) Ukuphakamisa uwoyela isilinda: isigaba sesithathu esiyinhlanganisela isilinda uwoyela isakhiwo, ifakwe one-way throttle valve; ukuphakamisa nokumisa i-derrick, i-valve yendlela eyodwa yokuvikela ukuvikela amandla adonsela phansi ngesikhathi senqubo yokufika kwe-derrick, nokuvikela ukuphepha kokuphakanyiswa nokuhlalisa kwe-derrick. Lo mshini ufakwe amasilinda aphakamisa kabili.

l Isakhiwo kanye nomgomo wokusebenza: Isakhiwo siqukethe isilinda, ipiston yezinga lokuqala, ipiston yezinga lesibili, ipiston yezinga lesithathu, indandatho yomhlahlandlela, indandatho yokuvala nezinye izingxenye. Ikhanda lesilinda lifakwe i-pin ear plate, exhunywe epuleti lendlebe elingashintshi ku-frame cross cross ngophini. I-piston rod yesiteji sesithathu ixhunywe kuphini lozimele lomnyango we-derrick ophansi ngendlela efanayo. Ama-plungers ezinga lokuqala nelesibili anesakhiwo sesenzo sendlela eyodwa. Ngaphansi kwesenzo sikawoyela we-hydraulic, i-plunger inweba ngamandla futhi ihoxise ngesisindo sayo uma ibuya. Ipiston yezinga lesithathu inesakhiwo sesenzo sezindlela ezimbili. Ngaphansi kwesenzo sikawoyela we-hydraulic, i-piston yezinga lesithathu inika amandla isandiso nokuhoxiswa. Isilinda esiphakamisayo sifakwe izimbobo zikawoyela ezintathu, i-P1, i-P2 ne-P3. Imbobo kawoyela i-P1 itholakala ekhanda le-cylinder, elixhuma igumbi lokusebenza le-plunger kanye negumbi le-piston lesiteji sesithathu elingenazintambo. Kukhona i-valve ye-throttle yendlela eyodwa endaweni yamafutha; I-oil port P2 itholakala endaweni yesithathu ye-piston rod, exhuma igumbi le-piston lesiteji sesithathu le-rodless. Kukhona imbobo ye-throttle emgodini wenduku kanye nephaseji likawoyela; imbobo kawoyela i-P3 itholakala esiteji sesithathu se-piston rod, exhuma igumbi lokusebenza le-plunger kanye nesiteji sesithathu sesiteji se-piston rodless, futhi ixhunywe ne-P1 kawoyela iphaseji. Kukhona i-throttle hole ephaseji likawoyela. Imbobo yokukhipha umoya inikezwa esihlokweni sesilinda se-piston yesigaba sesithathu sesilinda samafutha, futhi ipulaki yokukhipha umoya ifakiwe kuyo.

l Ukukhipha Umoya: Ngaphambi kokuphakanyiswa kanye nokuhlaliswa ngakunye kwe-derrick, umoya osesilindani sokuphakamisa kanye nesilinda esibona kude kufanele ukhululwe ngokuphelele. Uwoyela weHydraulic unomoya, futhi ukuvuza epayipini kubangela umoya kusilinda. Lapho isilinda esiphakamisayo nesilinda se-telescopic kumiswe isikhathi eside, umoya uzonqwabelana engxenyeni engenhla yesilinda. Lapho i-derrick iphakanyiswa futhi yehliswa, amathuba ezingozi azokwanda, umoya uzokhishwa, futhi izingozi ezifihliwe zezingozi zizoqedwa.

l Ukukhishwa komoya kwepayipi lesistimu: Vula i-valve yenaliti engu-E kuphaneli yokulawula yamavalvu ahlangene ayisithupha ukuze wenze isekethe ebushelelezi yamasilinda aphakamisayo i-P1 ne-P3, bese uxhuma ipayipi lokubuyisela uwoyela. Phakamisa isibambo sevalvu yokulawula isilinda, uwoyela we-hydraulic wepompo kawoyela ungena kusilinda esiphakamisayo nge-P1, bese ubuyela ethangini likawoyela nge-P3. Uhlelo lwe-hydraulic lusebenza ngaphandle komthwalo; i-hydraulic system isebenza ngaphandle komthwalo imizuzu emi-5 kuya kweyi-10, isuse ukuvuza epayipini kanye negesi yesilinda esiphakamisayo.

l Khipha umoya emgodini wenduku yepiston yesigaba sesithathu sesilinda esiphakamisayo: vala i-valve yenaliti E, futhi amasilinda okuphakamisa i-P1 ne-P3 enza isifunda esivaliwe. Phakamisa kancane isibambo se-valve yokulawula isilinda, unikeze uwoyela ocindezelayo egumbini eliphansi lesilinda eliphakamisayo, lawula ukucindezela kukawoyela ku-2 ~ 3MPa, vula ipulaki elopha esihlokweni se-cylinder sesigaba sesithathu se-cylinder, bese ukhipha. umoya ku-cylinder ephakamisa.

l Ukuhlolwa kokuvuza kwesistimu: Phakamisa kancane i-valve yokulawula isilinda, unikeze uwoyela wokucindezela ekamelweni eliphansi lesilinda eliphakamisayo, phakamisa kancane i-derrick, shiya i-100 ~ 200mm kude kubakaki bangaphambili be-derrick, yeka ukuphakamisa, futhi ugcine i-derrick. esimweni imizuzu emi-5. Hlola uhlelo lwama-hydraulic namapayipi, akufanele kube khona ukuvuza noma kuphi; bheka i-derrick, akufanele kube khona okusobala ukuthi ukuphi.

l Indlela yokuphepha: I-derrick iyasinda, futhi maningi amathuba ezingozi lapho uphakamisa futhi wehlisa i-derrick. Naka kakhulu ngesikhathi sokusebenza futhi ulandele ngokuqinile izinqubo zokusebenza. Izindlela zokuphepha eziningi zisethelwe isilinda sokuphakamisa okuphephile. Ngisho noma i-valve yokulawula i-cylinder ephakamisa ihluleka noma i-hose ye-hydraulic iphukile futhi yonakele, isilinda esiphakamisayo sizonciphisa ngokuphumelelayo isivinini sokwehlisa i-derrick futhi sivimbele izingozi ezinkulu.

l Ukuphakamisa i-derrick: Uwoyela we-hydraulic ungena ekamelweni lokusebenza le-cylinder kawoyela esuka echwebeni le-P1 ngokusebenzisa i-valve yendlela eyodwa. I-plunger yezinga lokuqala inweba kuqala. Ngemva kokufinyelela endaweni, i-plunger yezinga lesibili kanye nenduku yepiston yezinga lesithathu zinwebeka ngokulandelana. Ipiston yezinga lesithathu inenduku. Amafutha asemgodini abuya nge-P2. Njengoba ichweba le-P2 lifakwe imbobo yokudonsa, lapho i-piston yesiteji sesithathu inweba, ukuvulwa kwe-valve yokulawula kufanele kuncishiswe futhi isivinini sokunwetshwa kufanele sincishiswe. Uma kungenjalo, ukucindezela kwesistimu ye-hydraulic kuzokwanda;

l Yehlisa i-derrick: Uwoyela we-hydraulic ungena emgodini wepiston yesiteji sesithathu ukusuka ku-P2, ephusha i-piston ukuze ihoxise. Amafutha emgodini ongenazintambo abuyela emafutheni ngokusebenzisa i-P1 throttle, futhi isilinda sihlehla kancane ukuvimbela amandla adonsela phansi; Ukuhlehlisa ukulandelana kwe-plunger ngayinye ne-piston ithi: okokuqala, i-piston yesiteji sesithathu iyahoxiswa. Ngemva kokufika kulesi sikhundla, ama-plungers esiteji sesibili kanye nesigaba sokuqala ahlehla ngokulandelana. Lapho ama-plunger esibili kanye ne-primary ehlehla, ahlehla ngesisindo sawo ngaphandle kokunikeza uwoyela we-hydraulic kusilinda. Ngalesi sikhathi, isivinini senjini singancishiswa futhi isibambo sokusebenza sibuyela kancane kancane ku-derrick.

8) I-Telescopic cylinder, i-hydraulic telescopic enezitezi ezimbili iderrick.

l Ukwakheka kwesakhiwo: Isilinda ende ye-plunger, enobude obuphelele obuyi-14 ukuya ku-16m. Kukhona imbobo yamafutha ekugcineni kwe-plunger, futhi i-valve ye-throttle yendlela eyodwa ifakwe emgudwini wamafutha; ikhanda lesilinda lifakwe ipulaki yokopha. Umzimba wesilinda samafutha uboshelwe emzimbeni ongaphezulu we-derrick ngamabhawodi amise okuka-U, futhi ingaphezulu licindezelwa eringini yesihlalo se-derrick beam. Ingxenye engezansi ye-plunger rod ifakwe ipuleti lokuxhuma, eliboshelwe emgodleni womzimba ophansi we-derrick.

l Inqubo yokusebenza. I-derrick esitezi sesibili inwetshiwe, futhi i-valve yokulawula yesilinda sikawoyela we-telescopic isetshenziswa ukuze iphakame. Amafutha okucindezela angena kusilinda ngembobo kawoyela ekugcineni kwe-plunger rod, i-valve yendlela eyodwa, kanye ne-hollow plunger, esunduza isilinda ukuze inwebe, eshayela umzimba ongaphezulu we-derrick ukuthi ukhuphuke eduze kwethrekhi. I-derrick isendaweni futhi indlela yephini lokukhiya ikhiywa ngokuzenzakalelayo. I-derrick yesitezi sesibili ihoxisiwe, futhi iphinikhodi yokuphepha ikhishwa mathupha. Okokuqala, ivalvu yokulawula isilinda ye-telescopic isetshenziselwe ukuphakamisa phezulu, ukuze i-derrick yesitezi sesibili ikhuphuke kancane cishe ngo-200mm. Iphinikhodi yokukhiya iyazivula ngokuzenzakalelayo, bese ivalvu yokulawula isilinda ye-telescopic isetshenziselwe ukusunduza phansi, futhi uwoyela we-hydraulic kusilinda Ukucindezela okukhiqizwa ukuzisinda kwe-derrick yesitezi sesibili kugeleza ku-cylinder ngokusebenzisa i-throttle. ichweba kanye nembobo kawoyela ekugcineni kwe-plunger. I-derrick yesitezi sesibili iyawa. Isivinini esiwayo silungiswa yi-degree yokuvula ye-valve yendlela eyodwa kanye nevalvu yokulawula isilinda ye-telescopic.

l Indlela yokuphepha: I-derrick esitezi sesibili inzima kakhulu, futhi maningi amathuba ezingozi lapho uphakamisa futhi wehlisa i-derrick. Naka kakhulu ngesikhathi sokusebenza futhi ulandele ngokuqinile izinqubo zokusebenza. Isilinda se-telescopic sokuphepha sifakwe i-valve yendlela eyodwa. Ngisho noma i-valve yokulawula isilinda ihluleka noma ipayipi elisebenza ngamanzi lidabukile futhi lilimele, isilinda sizonciphisa isivinini sokwehla kwe-derrick futhi sivimbele izingozi ezinkulu.

l I-Exhaust Air: Ngemva kokuba isilinda sibekwe isikhathi esithile, umoya uzongena usuka esigxivizweni. Isilinda esisanda kufakwa sinomoya omningi ngaphakathi. Ngakho-ke, ngaphambi kokusebenza ngakunye kwesilinda se-telescopic, umoya osesilinda se-telescopic kufanele ukhululwe ukuze kuvinjelwe inqubo yokwandisa yesilinda. Ukukhasa. Phakamisa kancane isibambo se-valve yokulawula isilinda, unikeze uwoyela wokucindezela kusilinda se-telescopic, futhi ulawule ukucindezela kukawoyela ku-2 kuya ku-3 MPa. Vula ipulaki ye-vent phezulu kwesilinda ukuze ukhiphe umoya kusilinda se-telescopic. Ngemva kokukhipha amanzi, qinisa i-nati. Unganyakazi ngenkathi uhlanza. Vula i-latch yokuphepha ye-derrick.

9) Isilinda Sokubamba: Isilinda sinesakhiwo sepiston esinezinhlangothi ezimbili, futhi izisetshenziswa ze-buffer zihlinzekwa kuzo zombili iziphetho zekhanda le-cylinder kanye nekhava ye-cylinder ukuvimbela umthelela we-hydraulic we-cylinder. Lapho induku ye-piston yesilinda samafutha ihlehla, intambo yekhanda lekati ye-tong yokuphakamisa iyaqiniswa ukuze iqinise futhi ixegise intambo yokubhoboza; induku yepiston iyanwebeka futhi intambo yekhanda lekati iyabuya.

I-10) I-Winch encane ye-Hydraulic: indlela yokunciphisa iplanethi, ifakwe i-valve yebhuleki nebhalansi, iphephile ukuphakamisa izinto futhi ingahamba emoyeni.

11) I-valve ephindwe kabili: Ifakwe engxenyeni engezansi yebhokisi lokulawula lomshini wokubhoboza, iqukethe ipuleti levalvu yokufaka uwoyela, ipuleti levalvu yokubuyisela uwoyela kanye namapuleti amavalvu amabili asebenzayo. Ucezu lwe-valve yokungena kawoyela lufakwe i-valve yokuphepha ukulungisa ingcindezi yokusebenza engena ku-valve ephindwe kabili. Khulula futhi uqinise inathi, bese usonta isikulufu sokulungisa ukuze ushintshe ukucindezela kokulungisa kwevalvu yokuphepha. Lapho i-screw in, ingcindezi yokulungisa iyanda, futhi lapho i-screw out, ingcindezi yokulungisa iyancipha. Qaphela ukuthi ngemva kokulungiswa, qinisa ikepisi elingemuva bese ukhiya nati elilungisayo. Ipuleti le-valve elisebenzayo lilawulwa ngesandla.

A. Ivalve yesilinda ye-tong I: Ilawula isilinda sokuphakamisa ithong I ukuze inwebe futhi ihlehle ukuze ixegise futhi iqinise intambo yekhanda lehange. I-valve core isethwe ngokuma kwe-valve entantayo ukuze yakhe isekethe yesilinda esihlukile. Amafutha epompo yamafutha kanye namafutha omgodi wenduku angena emgodini ongenazintambo we-cylinder yamafutha ngesikhathi esifanayo, okwenza ukuba induku ye-piston ikhule ngokushesha; i-valve core spring ibuya, ikhulule isibambo, futhi i-valve core ibuyela ngokuzenzakalelayo Esikhundleni sokungathathi hlangothi, ukunyakaza kwesilinda kuyama.

B. Ivalve ye-tong yesilinda II: Ilawula isilinda sokuphakamisa ithong II ukuze inwebe futhi ihlehle ukuze ixegise futhi iqinise intambo yekhanda lehange. I-valve core isethwe ngokuma kwe-valve entantayo ukuze yakhe isekethe yesilinda esihlukile. Amafutha epompo yamafutha kanye namafutha omgodi wenduku angena emgodini ongenazintambo we-cylinder yamafutha ngesikhathi esifanayo, okwenza ukuba induku ye-piston ikhule ngokushesha; i-valve core spring ibuya, ikhulule isibambo, futhi i-valve core ibuyela ngokuzenzakalelayo Esikhundleni sokungathathi hlangothi, ukunyakaza kwesilinda kuyama.

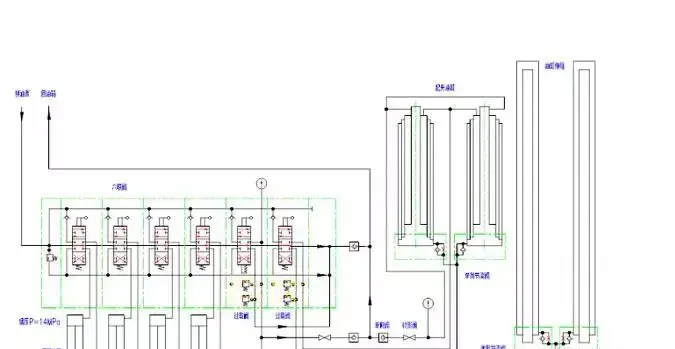

13) I-Valve ehlanganisiwe eyisithupha: ifakwe ebhokisini lokulawula le-hydraulic ohlangothini lwesobunxele senhlalo. Siqukethe ipuleti ye-oyela i-valve valve, ipuleti ye-valve ye-valve yokubuyisa uwoyela namapuleti ayisithupha asebenzayo. Ucezu lwe-oyili ye-valveve valve luhlome nge-valve yokuphepha ukulungisa ingcindezi yokusebenza efaka i-valve ehlanganisiwe. Khulula futhi uqinise i-nati, futhi usonte isikulufa sokulungisa ukuze ushintshe ingcindezi yokulungisa ye-valve yezokuphepha. Lapho ugoqa, ingcindezi yokulungisa inyuka, futhi lapho ugoqa ngaphandle, ingcindezi yokulungisa iyancipha. Qaphela ukuthi ngemuva kokulungiswa, qinisa isikejana sangemuva bese ukhiya i-nati yokulungisa.

- Ivalve yesilinda esiphuma kwesokudla sangaphambili: ilawula isilinda esiphuma kwesokudla ngaphambili kohlaka, iphakamisa futhi yehlise uhlaka, futhi ilungisa izinga lohlaka. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema.

- Ingaphambili le-Outrigger Cylinder Valve Valve: Ilawula isilinda se-Outrigger yangakwesobunxele ngaphambili kohlaka, ikhuphuke futhi yehlise uhlaka, futhi iguqule izinga lefreyimu. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema.

- I-Outracter Right Outrigger Cylinder valve: ilawula isilinda esilungile sokuqalisa ngemuva kohlaka. Phakamisa, wehlise futhi uleveli uhlaka. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema.

- I-OURTIGGER CERVERVER VALLVER YOKUQALA Phakamisa, wehlise futhi uleveli uhlaka. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema.

- Ukuphakamisa i-Cylinder Valve: Ilawula ukunyakaza kwesilinda sokuphakamisa ukukhulisa nokwehlisa i-derrick ephelele. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema. Zombili lezi zindawo zokukhipha uwoyela zifakwe ama-valves alayisha ngaphezulu ukuze zikhawulele ingcindezi efaka isilinda kawoyela futhi ithuthukise ukuphepha kokusebenza kwe-derrick.

- I-Teloscopic uwoyela isilinda se-bilinder I-PIN ye-Valeve Core Lock Pin ibekelwe indawo futhi isibambo sikhishwa. I-Valve Core isaqhubeka nokusebenza futhi isilinda kawoyela siyaqhubeka nokuhamba. Zombili lezi zindawo zokukhipha uwoyela zifakwe ama-valves alayisha ngaphezulu ukuze zikhawulele ingcindezi efaka isilinda kawoyela futhi ithuthukise ukuphepha kokusebenza kwe-derrick.

13) I-Valve ehlanganisiwe eyisithupha: ifakwe ebhokisini lokulawula le-hydraulic ohlangothini lwesobunxele senhlalo. Siqukethe ipuleti ye-oyela i-valve valve, ipuleti ye-valve ye-valve yokubuyisa uwoyela namapuleti ayisithupha asebenzayo. Ucezu lwe-oyili ye-valveve valve luhlome nge-valve yokuphepha ukulungisa ingcindezi yokusebenza efaka i-valve ehlanganisiwe. Khulula futhi uqinise i-nati, futhi usonte isikulufa sokulungisa ukuze ushintshe ingcindezi yokulungisa ye-valve yezokuphepha. Lapho ugoqa, ingcindezi yokulungisa inyuka, futhi lapho ugoqa ngaphandle, ingcindezi yokulungisa iyancipha. Qaphela ukuthi ngemuva kokulungiswa, qinisa isikejana sangemuva bese ukhiya i-nati yokulungisa.

A. I-Front Right Outricger Cylinder Valve Valve: Ilawula isilinda se-Outrigger esilungile ngaphambili kohlaka, ikhuphuke futhi yehlise uhlaka, futhi iguqule izinga lohlaka. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema.

B. I-Offler Cylinder Cylinder Cylinde: ilawula isilinda se-Oniffger Cylinder yangakwesobunxele ngaphambili kohlaka, ikhuphuke futhi yehlise uhlaka, futhi iguqule izinga lefreyimu. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema.

C. I-Cyserve ye-Cylinder Cylinder Cylinder Phakamisa, wehlise futhi uleveli uhlaka. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema.

D. I-Prewer Oured Cylinder Valve Valve: Ilawula isilinda sesinxele sesobunxele ngemuva kohlaka. Phakamisa, wehlise futhi uleveli uhlaka. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema.

E. Ukuphakamisa i-Cylinder valve: Ilawula ukunyakaza kwesilinda sokuphakamisa ukukhulisa nokwehlisa i-derrick ephelele. I-Valve Core Spring ibuya, khipha isibambo, i-Valve Core ngokuzenzakalelayo ibuyela endaweni yokungathathi hlangothi, futhi ukunyakaza kwe-cylinde kuyema. Zombili lezi zindawo zokukhipha uwoyela zifakwe ama-valves alayisha ngaphezulu ukuze zikhawulele ingcindezi efaka isilinda kawoyela futhi ithuthukise ukuphepha kokusebenza kwe-derrick.

F. I-Telescopic uwoyela isilinda se-lyrinder I-PIN ye-Valeve Core Lock Pin ibekelwe indawo futhi isibambo sikhishwa. I-Valve Core isaqhubeka nokusebenza futhi isilinda kawoyela siyaqhubeka nokuhamba. Zombili lezi zindawo zokukhipha uwoyela zifakwe ama-valves alayisha ngaphezulu ukuze zikhawulele ingcindezi efaka isilinda kawoyela futhi ithuthukise ukuphepha kokusebenza kwe-derrick.

2.Stering Hydraulic System

Liqukethe izinto ezilandelayo:

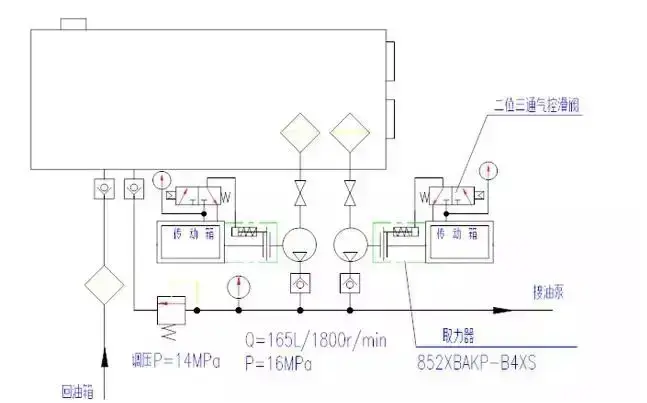

1) Iphampu lokuqondisa le-oli lifakwa ethekwini elikhipha amandla enjini. Injini ijikeleza futhi ishayela ipompo kawoyela ukuze isebenze.

2) Isihlungi samafutha sokucwilisa sinesakhiwo esibonisa ukucaca ngaphandle kwethangi. Ifakwe ohlangothini lwethangi lamafutha e-hydraulic. Ishubhu lokumunca lamafutha ligxiliswa ngaphansi kwezinga loketshezi ethangini lamafutha. Ikhanda lokuhlunga livezwa ngaphandle kwethangi lamafutha. Ifakwe i-valve yokuzibeka obala, i-bypass valve kanye nento yokuhlunga. Lapho ungena esikhundleni noma ukuhlanza into yokuhlunga yamadivayisi afana nokungcoliswa kwama-transmitters, kungenziwa ngaphandle kwethangi. Kulula ukunqamula nokufaka, bese uwoyela ethangini ngeke uphume.

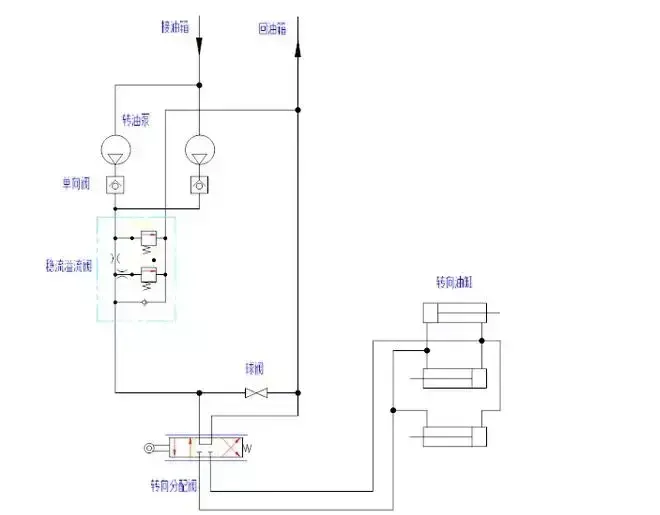

3) I-valve echichimayo neyokugeleza iguqula ingcindezi yohlelo, ivimbela ukulayisha ngokweqile kohlelo, futhi ivikele ukuphepha kohlelo kanye nezinto; Ipompo kawoyela isebenza ngejubane eliphezulu, futhi lapho izinga lokugeleza likhulu kakhulu, ukugeleza kuphambukisiwe emuva ethangini ukuze kuqinisekiswe izinga eliqinile lokugeleza kohlelo. Bheka umfanekiso (impumuzo kanye nokuqina kokuqina kwe-valve)

4) I-valve yokuqondisa i-valve elandela ukuqondiswa kwesondo lokuqondisa, ilawule ukugeleza kokugeleza kwamafutha e-hydraulic, inikezela ngesilinda sokuqondisa, bese icindezela amasondo akwa-axle angaphambili ukuze ajike kwesokunxele nakwesokudla. Bheka umfanekiso (ukuqondisa ukuhambisa i-valve)

5) Ukuqondisa isilinda, isilinda se-piston enezindlela ezimbili, esisodwa sangaphambi kwama-axles amathathu angaphambili; Ikhanda le-Piston RED lixhumeke kwi-Steireing Knuckle ARM ukulawula i-angle engela yesondo. Bheka isithombe (isilinda esiqondisa)

- I-valve yebhola ixhunyiwe phakathi kwepayipi lokucindezela kanye nepayipi elibuyayo kawoyela. Lapho i-rig yokushayela isebenza, vula i-valve yebhola ukuze uthulule uhlelo futhi uvikele izingxenye zohlelo.