Ukuhlaziywa kanye nokusetshenziswa kwe-DOUBLE COUNTERBALANCE VALVE

2024-02-20Izimo zokusebenza zemishini yobunjiniyela ziyinkimbinkimbi. Ukuze ugweme ukuma noma ukushesha ngokweqile ohlelweni lokuhambisa ngama-hydraulic,ama-valve ebhalansizivame ukusetshenziselwa ukuxazulula le nkinga. Kodwa-ke, ukudlidliza kokunikezwa kwemvamisa kuzokwenzeka ngesikhathi sokusebenza kokulayisha, futhi akukwazi ukuxazulula inkinga yokunyakaza okuphindaphindayo noma okuzungezisayo. izinkinga zokuma kanye nokushesha ngokweqile. Ngakho-ke, lesi sihloko sethula i-valve yokulinganisa yezindlela ezimbili ukuze kuthuthukiswe ukushiyeka kwe-valve yokulinganisa.

1.Isimiso sokusebenza se-valve yokulinganisa yezindlela ezimbili

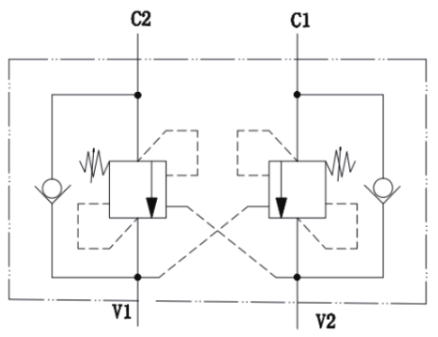

I-valve yokulinganisa yezindlela ezimbili yenziwe ngamavalve okulinganisa afanayo axhunywe ngokuhambisana. Uphawu lwesithombe lunjengoba luboniswe kuUmfanekiso 1. Imbobo kawoyela yokulawula ixhunywe endaweni yokungena kawoyela yegatsha ngakolunye uhlangothi. I-valve yokulinganisa enezinhlangothi ezimbili yakhiwe ngomongo we-valve oyinhloko, umkhono we-valve wendlela eyodwa, isiphethu se-mesh core esiyinhloko kanye nesiphethu se-valve yendlela eyodwa. Imbobo yokulawula i-throttling yakhiwe i-valve eyinhloko ye-valve yebhalansi kanye nomkhono we-valve yendlela eyodwa.

Umfanekiso 1:Isimboli esiyisithombe se-valve yokulinganisa yezindlela ezimbili

I-valve yokulinganisa yezindlela ezimbili ikakhulukazi inemisebenzi emibili: umsebenzi wokukhiya osebenza nge-hydraulic kanye nomsebenzi wokulinganisa oguqukayo. Umgomo wokusebenza wale misebenzi emibili uhlaziywa kakhulu.

Umsebenzi webhalansi enamandla: Ngokucabanga ukuthi uwoyela ocindezelayo ugeleza usuka ku-CI uya ku-actuator, uwoyela ocindezelayo unqoba amandla asentwasahlobo e-valve yendlela eyodwa kuleli gatsha, okubangela ukuthi imbobo yokulawula i-throttle valve ivuleke, futhi uwoyela wokucindezela ugelezela ku-actuator. .

Amafutha abuyayo asebenza kumongo we-valve oyinhloko waleli gatsha kusuka ku-C2, futhi kanye namafutha okucindezela ku-port yokulawula, kuqhuba ukunyakaza kwe-valve core enkulu. Ngenxa yamandla anwebekayo engqikithi ye-valve eyinhloko, igumbi lokubuyisela uwoyela le-actuator linomfutho ongemuva, ngaleyo ndlela liqinisekisa ukunyakaza okushelelayo kwe-actuator. Lapho amafutha okucindezela egeleza esuka ku-C2 eya ku-actuator, i-valve yokuhlola ku-C2 kanye nomgogodla oyinhloko we-valve ekuhambeni kwe-C1 (ekuqaleni, isimiso sokusebenza sifana nangenhla).

Umsebenzi wokukhiya i-Hydraulic: Uma i-VI ne-V2 iku-zero ingcindezi, ingcindezi kawoyela esikhaleni sokulawula sevalvu yebhalansi yezindlela ezimbili incane kakhulu, cishe i-OMpa. Ingcindezi kawoyela ku-actuator kanye ne-actuator ayikwazi ukunqoba amandla entwasahlobo we-valve core eyinhloko, ngakho-ke i-valve core ayikwazi ukunyakaza, futhi i-valve yendlela eyodwa ayinakho ukuqhutshwa okungajulile, futhi imbobo yokulawula i-throttle valve isesimweni esivaliwe. Izilawuli ezimbili ze-actuator zivaliwe futhi zingahlala kunoma iyiphi indawo.

2.Izibonelo zobunjiniyela zama-valve okulinganisa izindlela ezimbili

Ngokuhlaziywa okungenhla, i-valve yebhalansi yezindlela ezimbili ayenzi nje kuphela ukuthi i-hydraulic actuator ihambe kahle, kodwa futhi inokusebenza kokukhiya kwe-hydraulic, ngakho-ke isetshenziswa kabanzi. Lesi sihloko sethula ikakhulukazi izibonelo ezithile zobunjiniyela zomthwalo osindayo nokunyakaza okuphindaphindayo.

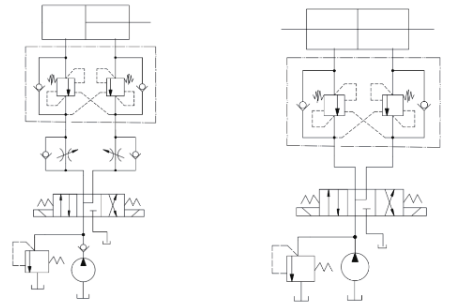

Ukusetshenziswa komgomo we-hydraulic emilenzeni eyinhloko yomshini wokumisa ibhuloho lesitimela esinesivinini esikhulu kukhonjisiwe ku.Umfanekiso 3. Imilenze eyinhloko yomshini wokumisa ibhuloho lesitimela esinesivinini esiphezulu iphumulile. Ayisekeli kuphela ivolumu yemoto yomshini wokumisa ibhuloho ngokwawo, kodwa futhi umthamo wemishayo kakhonkolo. Umthwalo mkhulu futhi isikhathi sokusekela side. Ngalesi sikhathi, kusetshenziswa umsebenzi wokukhiya i-hydraulic we-valve yebhalansi yezindlela ezimbili. Lapho umshini wokumisa ibhuloho wehla wenyuka, ngenxa yomthamo wemoto enkulu, udinga ukuhamba kahle. Ngalesi sikhathi, ibhalansi eguquguqukayo ye-valve yebhalansi yezindlela ezimbili isetshenziswa. Kukhona futhi i-valve yendlela eyodwa ye-throttle ohlelweni, okwandisa ukucindezela kwangemuva kwe-actuator, kuthuthukise ngokwengeziwe ukuzinza kwe-Movement.

Umfanekiso 2Imilenze yogodo eyinhloko yomshini wokumisa ibhuloho lesitimela esinesivinini esikhulu Umfanekiso 3 I-boom yesikhulumi somsebenzi wasemoyeni

Ekusetshenzisweni kwama-boom kumapulatifomu omsebenzi wasemoyeni, umdwebo we-hydraulic schematic uboniswa kuMfanekiso 3 [3]. Uma i-engeli ye-luffing ye-boom ikhula noma yehla, ukunyakaza kuyadingeka ukuze kube bushelelezi, futhi i-valve yebhalansi yezindlela ezimbili ivimbela ukuma noma ukusheshisa kakhulu phakathi nokunyakaza kwayo okuphindaphindayo. Kuvela ingozi ethile.

3.Isigaba

Lesi sihloko sihlaziya ngokuyinhloko ukuhlaziywa kwesimiso sokusebenza kanye nokusetshenziswa kobunjiniyela okungokoqobo kwe-valve yebhalansi yezindlela ezimbili kusukela kumsebenzi wokukhiya osebenza ngomshini wokudonsa amanzi kanye nomsebenzi webhalansi oguqukayo, futhi inokuqonda okujulile kwe-valve yebhalansi yezindlela ezimbili. Inenkomba ethile ekuthuthukisweni nasekusetshenzisweni kwayo.