- English

- Chinese

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Iimfuno zofakelo kunye nezilumkiso zemibhobho ye-hydraulic, amacandelo e-hydraulic kunye nezinto ezincedisayo kwiinkqubo zamanzi

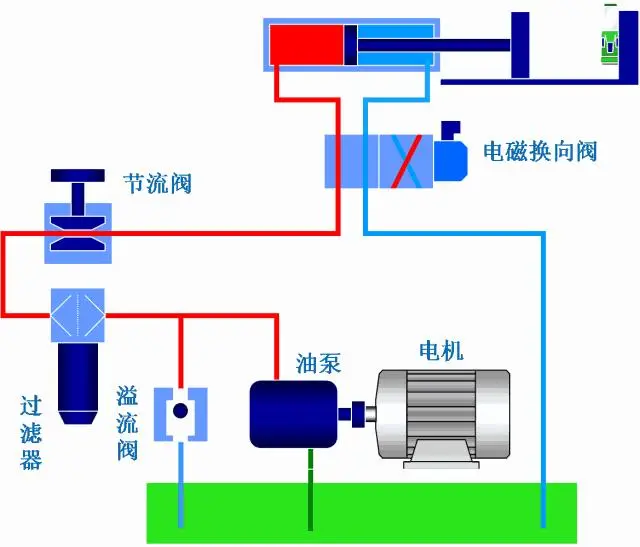

2023-10-26Ufakelo lwenkqubo yolwelo, kubandakanywa nofakelo lwemibhobho yolwelo lwamanzi, izakhi zamanzi, izixhobo ezincedisayo, njl.njl., kubaluleke kakhulu ukudibanisa iiyunithi ezahlukeneyo okanye amacandelo enkqubo ngokusebenzisa izihlanganisi zolwelo (igama jikelele lemibhobho yeoli kunye namalungu) okanye i-hydraulic manifolds. ukwenza isekethe. Eli nqaku likwabelana ngeemfuno zofakelo kunye nezilumkiso zemibhobho ye-hydraulic, i-hydraulic components, kunye nezixhobo ezincedisayo kwiinkqubo ze-hydraulic.

Ngokwendlela yokudibanisa yamacandelo olawulo lwe-hydraulic, inokwahlulwa ibe: uhlobo oludibeneyo (uhlobo lwesikhululo se-hydraulic); uhlobo olunatyisiweyo. Zombini ezi fom kufuneka zidityaniswe ngokudityaniswa kolwelo.

1.Ukufakwa kwamacandelo e-hydraulic

Ufakelo kunye neemfuno ezithile zamacandelo ahlukeneyo e-hydraulic. Amacandelo e-hydraulic kufuneka ahlambuluke nge-kerosene ngexesha lofakelo. Onke amacandelo e-hydraulic kufuneka atyhutyhe uxinzelelo kunye novavanyo lomsebenzi wokutywina. Emva kokuphumelela uvavanyo, ukufakela kunokuqalisa. Izixhobo ezahlukeneyo zolawulo oluzenzekelayo kufuneka zilinganiswe phambi kofakelo ukunqanda iingozi ezibangelwa kukungachaneki.

Ukufakwa kwamacandelo e-hydraulic ikakhulu kubhekiselele ekufakweni kwee-valve ze-hydraulic, iisilinda ze-hydraulic, iimpompo ze-hydraulic kunye nezixhobo ezincedisayo.

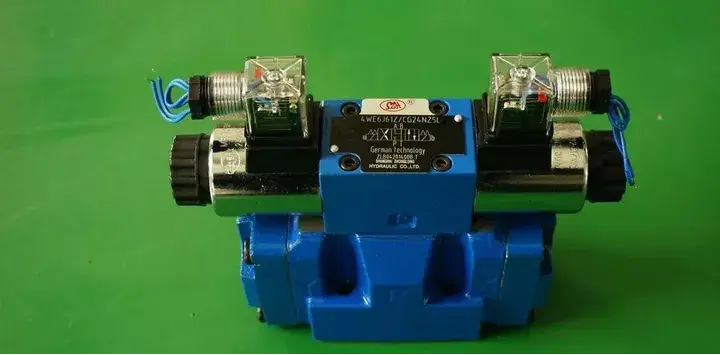

2. Ufakelo kunye neemfuno zeevalvu zehydraulic

Ngaphambi kokufaka izakhi ze-hydraulic, amacandelo angapakishwanga e-hydraulic kufuneka aqale ajonge isatifikethi sokuthotyelwa kunye nokuphonononga imiyalelo. Ukuba imveliso efanelekayo kunye neenkqubo ezipheleleyo, kwaye akusiyo imveliso egcinwe kwindawo evulekile ixesha elide kwaye idibene ngaphakathi, akukho vavanyo olongezelelweyo olufunekayo kwaye alukhuthazwa. Iyakwazi ukuchithwa kwaye ihlanganiswe ngokuthe ngqo emva kokucoca.

Ukuba ukungasebenzi kakuhle kwenzeka ngexesha lokuvavanya, amacandelo kufuneka adityaniswe kwaye aphinde ahlanganiswe kuphela xa isigwebo sichanekile kwaye siyimfuneko. Ngokukodwa kwiimveliso zangaphandle, ukuchithwa okungahleliwe kunye nokuhlanganisana akuvumelekanga ukuphepha ukuchaphazela ukuchaneka kwemveliso xa ishiya imveliso.

Nika ingqalelo koku kulandelayo xa ufaka iivalvu zehydraulic:

1) Xa ufaka, nikela ingqalelo kwindawo yokungena kweoli kunye nokubuyisela i-port yecandelo ngalinye le-valve.

2) Ukuba indawo yokufakela ayichazwanga, kufuneka ifakwe kwindawo ekulungele ukusetyenziswa kunye nokugcinwa. Ngokuqhelekileyo, i-valve yokulawula i-directional kufuneka ifakwe kunye ne-axis horizontal. Xa ufaka i-valve yokubuyisela umva, i-screws ezine kufuneka ziqiniswe ngokulinganayo, ngokuqhelekileyo zibe ngamaqela e-diagonals kwaye ziqiniswe ngokuthe ngcembe.

3) Iivalve ezifakwe nge-flanges, i-screws ayikwazi ukuqiniswa ngokugqithiseleyo. Ukuqiniswa kakhulu ngamanye amaxesha kunokubangela ukutywinwa kakubi. Ukuba itywina lokuqala okanye imathiriyeli ayinakuhlangabezana neemfuno zokutywinwa, imo okanye imathiriyeli yetywina kufuneka itshintshwe.

4) Ukuze kube lula ukuvelisa kunye nokufakwa, ezinye iivalve zihlala zinemingxuma emibini enomsebenzi ofanayo, kwaye engasetyenziswanga kufuneka ivalwe emva kokufakwa.

5) Iivalvu ezifuna ukulungiswa ngokuqhelekileyo zijikeleza nge-clockwise ukwandisa ukuhamba kunye noxinzelelo; Jikelezisa ngokunxamnye newotshi ukunciphisa ukuhamba okanye uxinzelelo.

I-6) Ngexesha lofakelo, ukuba ezinye iivalve kunye neengxenye zokudibanisa azifumaneki, kuvunyelwe ukusebenzisa i-valve ye-hydraulic kunye nesantya sokuhamba esidlula i-40% yokuhamba kwayo.

3. Ukufakwa kunye neemfuno ze-hydraulic cylinder

Ukufakwa kwe-cylinder ye-hydraulic kufuneka kuthembeke. Akufuneki kubekho ukudodobala kuqhagamshelo lwemibhobho, kwaye umphezulu onyukayo we-cylinder kunye ne-sliding surface yepiston kufuneka igcine i-parallelism eyaneleyo kunye ne-perpendicularity.

Nika ingqalelo koku kulandelayo xa ufaka isilinda esiqhutywa ngamanzi:

I-1) I-cylinder ehambayo enesiseko sonyawo olusisigxina, i-axis yayo ephakathi kufuneka igxininise kunye ne-axis yamandla omthwalo ukuze ugweme ukubangela imikhosi yecala, enokubangela ukuba kube lula ukunxiba isitywina kunye nomonakalo wepiston. Xa ufaka i-cylinder ye-hydraulic yento ehambayo, gcina i-cylinder ihambelana nolwalathiso lokuhamba kwezinto ezihambayo kwindawo yesikhokelo.

I-2) Faka i-screw ye-gland yokutywina yebhloko ye-hydraulic cylinder block kwaye uyiqinise ukuqinisekisa ukuba i-piston iyahamba kwaye idada ngexesha lokubetha okupheleleyo ukukhusela impembelelo yokwandiswa kwe-thermal.

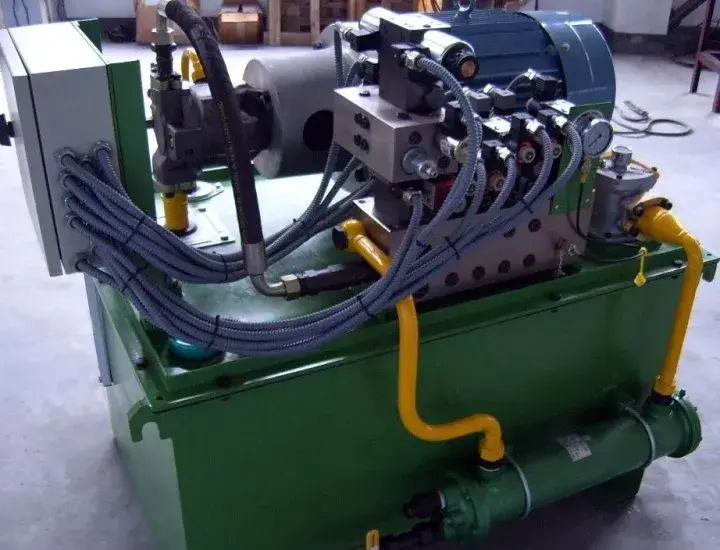

4. Ufakelo kunye neemfuno zempompo ye-hydraulic

Xa ipompo ye-hydraulic ihlelwe kwitanki eyahlukileyo, kukho iindlela ezimbini zokufakela: i-horizontal and vertical. Ufakelo oluthe nkqo, imibhobho kunye neepompo zingaphakathi kwetanki, okwenza kube lula ukuqokelela ukuvuza kweoli kunye nokubonakala kucocekile. Ukufakela okuthe tye, imibhobho ibonakaliswe ngaphandle, okwenza ukufakela kunye nokugcinwa kube lula ngakumbi.

Iimpompo zeHydraulic azivumelekanga ngokubanzi ukuba zithwale imithwalo yeradial, ngoko ke iimotor zombane ziqhele ukusetyenziselwa ukuqhuba ngokuthe ngqo kwi-elastic couplings. Ngexesha lofakelo, kuyimfuneko ukuba i-shafts ye-motor kunye nepompo ye-hydraulic kufuneka ibe ne-concentricity ephezulu, ukuphambuka kwabo kufuneka kube ngaphantsi kwe-0.1mm, kwaye i-angle inclination angle ayifanele ibe ngaphezu kwe-1 ° ukuphepha ukongeza umthwalo owongezelelweyo kwi-shaft yepompo. kwaye ibangela ingxolo.

Xa ibhanti okanye ukuhanjiswa kwegesi kuyimfuneko, ipompo ye-hydraulic kufuneka ivunyelwe ukuba isuse imithwalo ye-radial kunye ne-axial. Iinjini ze-hydraulic zifana neepompo. Ezinye iinjini zivumelekile ukuba zithwale umthwalo othile we-radial okanye i-axial, kodwa akufanele idlule ixabiso elivumelekileyo elichaziweyo. Ezinye iimpompo zivumela ukuphakama okuphezulu kokufunxa. Ezinye iimpompo zichaza ukuba izibuko lokufunxa i-oyile kufuneka libe ngaphantsi komgangatho we-oyile, kwaye ezinye iimpompo ezingenasakhono sokuzilungisa zifuna impompo eyongezelelweyo yokuncedisa ukubonelela ngeoyile.

Nika ingqalelo koku kulandelayo xa ufaka impompo yoxinzelelo lwehydraulic:

I-1) I-inlet, i-outlet kunye ne-rotation direction yepompo ye-hydraulic kufuneka ihambelane neemfuno eziphawulwe kwimpompo, kwaye akufanele idibaniswe ngasemva.

2) Xa ufaka ukudibanisa, musa ukubetha i-shaft yepompo nzima ukuze ugweme ukulimaza i-rotor yepompo.

5. Ufakelo kunye neemfuno zamacandelo ancedisayo

Ukongeza kunxibelelwano lwamanzi, izixhobo ezincedisayo zenkqubo ye-hydraulic nazo zibandakanya izihluzi, i-accumulators, i-coolers kunye nezifudumezi, izixhobo zokutywina, ii-gauges zoxinzelelo, ukutshintshwa kwe-pressure gauge, njl njl. ngexesha lofakelo, kungenjalo baya kuchaphazela kakhulu ukusebenza okuqhelekileyo kwenkqubo ye-hydraulic.

Nika ingqalelo koku kulandelayo xa ufaka amacandelo ancedisayo:

1) Ufakelo kufuneka luqhutywe ngokuhambelana ngokungqongqo kunye neemfuno zoyilo kwaye ingqalelo kufuneka ihlawulwe ukucoceka kunye nobuhle.

2) Sebenzisa i-kerosene yokucoca kunye nokuhlola ngaphambi kokufakwa.

3) Xa uhlangabezana neemfuno zokuyila, cinga ngokulula ukusetyenziswa kunye nokugcinwa kangangoko kunokwenzeka.