The Advantages of Pilot Valves

2024-11-12Pilot valves are essential components in various hydraulic and pneumatic systems. They play a crucial role in controlling the flow and pressure of fluids, making them indispensable in many industrial applications. In this blog, we will explore the advantages of pilot valves and why they are a preferred choice in many systems.

1. Enhanced Control

One of the primary advantages of pilot valves is their ability to provide enhanced control over fluid flow. Pilot valves operate by using a small pilot signal to control a larger flow. This allows for precise adjustments in the system, enabling operators to fine-tune the performance of hydraulic and pneumatic systems. The ability to control flow with high precision is particularly beneficial in applications where accuracy is critical.

2. Increased Efficiency

Pilot valves contribute to the overall efficiency of hydraulic and pneumatic systems. By utilizing a small amount of fluid to control a larger volume, they minimize energy consumption and reduce waste. This efficiency not only lowers operational costs but also extends the lifespan of the system components by reducing wear and tear.

3. Compact Design

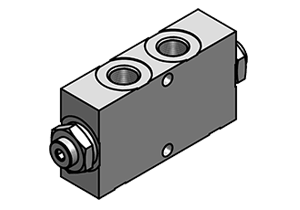

Pilot valves are typically smaller and lighter than traditional valves. This compact design allows for easier installation in tight spaces and reduces the overall weight of the system. The smaller size also means that pilot valves can be integrated into more complex systems without taking up excessive space, making them ideal for modern industrial applications.

4. Versatility

Another significant advantage of pilot valves is their versatility. They can be used in a wide range of applications, from simple on/off control to complex multi-function systems. Pilot valves can control various types of fluids, including oil, water, and air, making them suitable for diverse industries such as manufacturing, automotive, and aerospace.

5. Improved Safety

Pilot valves enhance the safety of hydraulic and pneumatic systems. By controlling the pressure and flow more effectively, they help prevent system overloads and potential failures. Many pilot valves are equipped with safety features, such as relief mechanisms, which further protect the system from damage. This focus on safety is crucial in industries where equipment failure can lead to hazardous situations.

6. Easy Maintenance

Maintenance is a critical aspect of any industrial system, and pilot valves are designed with this in mind. Their simple construction allows for easy access and servicing, reducing downtime and maintenance costs. Many pilot valves also have replaceable components, making it easier to maintain system performance without the need for complete replacements.

Conclusion

In summary, pilot valves offer numerous advantages that make them a vital component in hydraulic and pneumatic systems. Their ability to provide enhanced control, increased efficiency, compact design, versatility, improved safety, and easy maintenance makes them a preferred choice in various industrial applications. As technology continues to advance, the role of pilot valves will likely expand, further solidifying their importance in modern engineering solutions.