Sebopeho sa motheo le molao-motheo oa ho sebetsa oa hydraulic system

2023-10-25一、Kakaretso

Sistimi ea hydraulic e kenyelletsa pompo ea mantlha ea oli, tanka ea hydraulic, filthara, valve e fokotsang khatello, valve ea liphallelo, cylinder e phahamisang, cylinder ea telescopic, tong cylinder, cylinder ea outrigger, hydraulic motor, le ts'ebetso e fapaneng ea hydraulic. li-valve le likarolo tse ling. Pele lisebelisoa li tloha fekthering, likhatello tsa valve ea liphallelo, li-valve tse fokotsang khatello le li-valve tse fapaneng tsa khatello li fetotsoe ho netefatsa ts'ebetso e sireletsehileng ea tsamaiso ea hydraulic, 'me basebelisi ha ba lumelloe ho e fetola ka potlako nakong ea tšebeliso.

Sistimi ea hydraulic e kenyelletsa sistimi e kholo ea hydraulic le sistimi e tsamaisang metsi, 'me litsamaiso tse peli li arolelana tanka ea hydraulic.

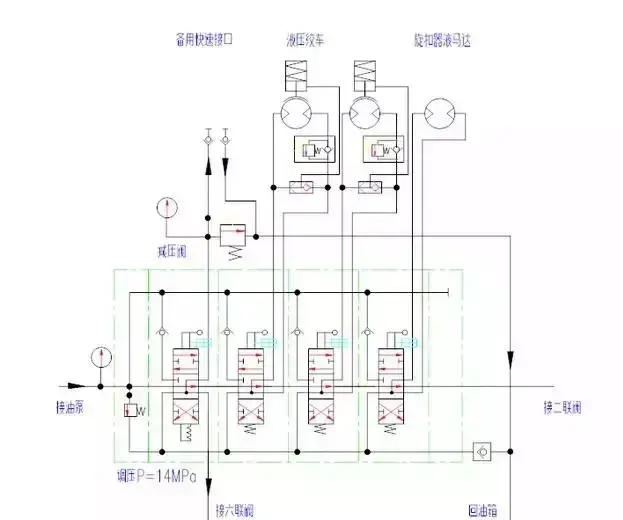

1.Main hydraulic system

Sistimi e kholo ea hydraulic e fana ka matla a hydraulic ho rig ea ho phunya nakong ea tokiso ea lisebelisoa le ts'ebetso ea ho lokisa ho cheka. E na le li-valve tse fapaneng ho laola ts'ebetso e nepahetseng le e bolokehileng ea sesebelisoa se seng le se seng sa hydraulic.

Matla a Hydraulic System

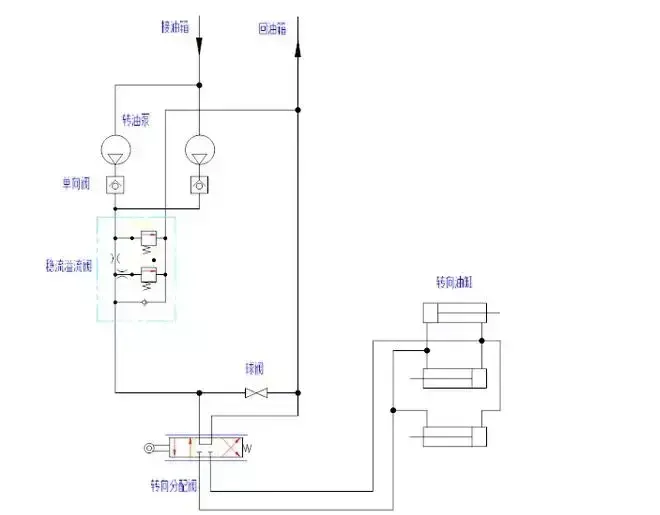

The steering hydraulic system e fana ka matla a hydraulic bakeng sa ho tsamaisa matla a hydraulic a axle e ka pele ea koloi. E na le li-valve tse fapaneng ho laola khatello, tataiso ea ho phalla le ho phalla ho tsitsitseng ha tsamaiso ea hydraulic, ho etsa bonnete ba hore tsamaiso ea koloi e bobebe, e tenyetseha, e bolokehile ebile e ka tšeptjoa.

3.Litšobotsi tsa sebopeho

Sisteme ea hydraulic e na le:

¨ Sistimi ea mantlha ea haeteroliki

¨ Sistimi ea hydraulic e tsamaisang

4.Main hydraulic system

E na le likarolo tse latelang:

1) Tanka ea oli ea Hydraulic: mabenkele, ho pholisa, ho thella le ho sefa oli ea hydraulic. Tanka ea mafura e kentsoe ka:

l Ho na le likoahelo tse peli tsa likoti tse kentsoeng ka holim'a tanka ea mafura. Sefahla sa moea sa hydraulic se kenngoa sekoahelong sa mokoti sebakeng sa ho khutla ha oli sa tanka ea mafura;

l Sesefa sa moea sa Hydraulic, se sefa moea o phallang ka tanka ea mafura, 'me se sefa oli ha tanka ea mafura e tlatsoa;

l Li-gauge tsa boemo ba mokelikeli, 2, li kentsoe ka lehlakoreng le ka pele la tanka ea oli. Ho na le litekanyo tse peli tsa boemo ba mokelikeli, tse phahameng le tse tlase. Tekanyo e phahameng ea boemo ba mokelikeli e bonts'a boemo ba oli ka mor'a hore derrick e theohe; tekanyo e tlase ea boemo ba mokelikeli e bonts'a boemo ba oli ka mor'a hore derrick e behoe;

l Sekala sa mocheso oa oli se kentsoe ka lehlakoreng le ka pele la tanka ea mafura ho lekanya mocheso oa oli ka tanka. Mocheso o tloaelehileng oa oli ea ho sebetsa o pakeng tsa 30 le 70°C. Ho na le likou tse peli tse kholo tsa ho khutlisa oli, tse behiloeng holim'a poleiti e tlase ea tanka ea mafura. Li na le li-valve tsa tsela e le 'ngoe' me li kopantsoe ka ho latellana. Phaephe e kholo ea ho khutlisa oli le kou ea ho khutlisa valve; valve ea tsela e le 'ngoe e koala ka bo eona ha e lokisa phaephe ea haeteroliki ho thibela tahlehelo ea oli ka tanka;

l Boema-kepe ba drain bo behiloe holim'a poleiti e ka tlase ea tanka ea mafura mme e koetsoe ka plug; bula polaka ho ntša tanka oli ea haeteroliki;

l Boema-kepe ba ho monya ba pompo e kholo ea oli bo behiloe ka lehlakoreng le ka pele la tanka ea mafura, 'me sefefo se seholo sa ho monya se kentsoe;

l Boema-kepe ba ho hula pompo ea oli e tsamaisoang bo behiloe ka lehlakoreng le ka pele la tanka ea mafura, 'me ho kentsoe sefahla sa oli se tsamaisang;

l Boema-kepe ba ho khutlisa oli ea sistimi ea ho tsamaisa bo behiloe holim'a poleiti e ka tlase ea tanka ea mafura mme e na le valve ea tsela e le 'ngoe. Belofo ea tsela e le 'ngoe e koala ka bo eona ha e lokisa phaephe ea haeteroliki ho thibela tahlehelo ea oli ka tankeng;

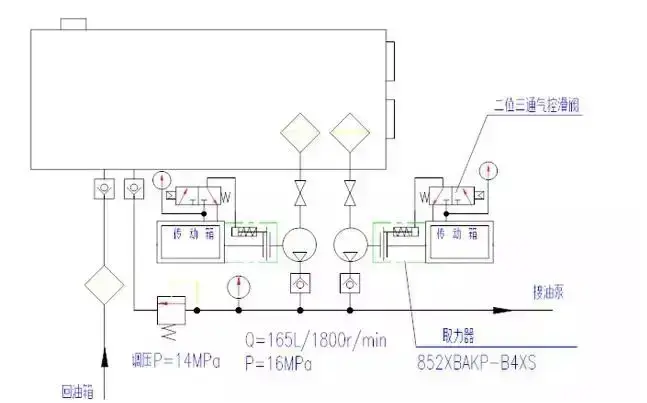

2) Pompo ea oli ea Hydraulic: Sebopeho sa gear e le 'ngoe, li-unit tse 2, ka ho latellana li kentsoe mabokoseng a mabeli a ho tlosa matla a hydraulic transmission, a tsamaisoa ke lebili la pompo ea torque converter. Ha enjene e potoloha, lebokose la ho tlosa matla le ka khanna pompo ea oli. Lebokose la ho tlosa motlakase le na le clutch ea hydraulic. Ha ho hlokahala khato ea hydraulic, "motsoako oa pompo ea metsi" oa lebokose la taolo ea mochine o ka sebelisoa 'me oa behoa sebakeng sa "pompo ea oli ke koala". Pompo ea oli ea I e kopantsoe ho hlahisa oli ea khatello ea ho sebetsa; sephethephethe se behiloe ho "pompo ea oli II". "Koala" boemo, pompo ea oli ea II e hokahane 'me e hlahisa oli ea khatello e sebetsang;. Sephethephethe se boemong bo sa nke lehlakore, 'me lipompo tsa oli ka bobeli lia lahla le ho emisa.

3) Valve ea liphallelo: sebopeho se tsamaisoang ke mofofisi, li-sets tsa 2, ka ho latellana li kentsoe qetellong ea oli ea pompo ea oli ea hydraulic. Fetola khatello ea sistimi, thibela khatello e ngata ea sistimi, 'me u sireletse polokeho ea sistimi le karolo.

Molao-motheo oa sebopeho sa valve ea liphallelo: E entsoe ka valve ea sefofane le selaete se seholo sa li-slide. Karolo ea valve ea sefofane e kenyelletsa 'mele oa li-valve, valve ea li-slide, seliba se laolang khatello le likarolo tse ling. Ho na le lesoba le lenyenyane a holim'a valve e kholo ea li-slide, e le hore oli ea khatello e tsoang linaheng tse ling e ka kena ka kamoreng e ka holimo ea B ea valve ea slide. Ha khatello ea hydraulic e sebetsang holim'a valve ea poppet e le tlase ho matla a pretightening ea selemo, valve ea pilot valve poppet e tla sebetsa tlas'a ketso ea matla a selemo. Kaha ha ho na phallo ea oli 'meleng oa li-valve, khatello ea hydraulic ka likamoreng tsa oli karolong e ka holimo le e ka tlaase ea valve ea slide e lekana. Ka hona, valve ea slide e boemong bo feteletseng ba qetellong e ka tlaase tlas'a ketso ea selemo se ka holimo sa selemo. Ho kena le ho tsoa ha valve ea liphallelo ho khaoloa ke valve ea slide, 'me valve ea liphallelo ha e phalle; ha khatello ea hydraulic e sebetsang holim'a valve ea poppet e eketseha ho lekana le matla a selemo ka lebaka la ho eketseha ha khatello ea ho kena ha valve ea liphallelo, valve ea poppet e sutumetsoa Bula, oli e ka kamoreng e ka holimo ea B ea valve ea slide e phallela ka har'a oli. ho tsoa ha belofo ka boema-kepe ba ho khutlisa oli b le bohareng ka lesoba la valve ea selaete, ebe e ts'ela ho khutlela tankeng ea oli. Ka nako ena, oli ea khatello ka sekoting sa oli sa valve ea liphallelo e phalla ho tloha ka lesoba le lenyenyane a. E khutlisetsoa holimo ho ea kamoreng ea B. Hobane ho na le tahlehelo ea khatello ha oli e feta ka lesoba le lenyenyane a, khatello e ka kamoreng ea B e tlase ho feta khatello ea oli e kenang, 'me phapang ea khatello e hlaha pakeng tsa likarolo tse ka holimo le tse tlaase. ea valve ea li-slide. Ka hona, tlas'a ketso ea phapang ea khatello pakeng tsa lipheletsong tse ka holimo le tse ka tlaase, valve ea li-slide e hlōla matla a selemo, 'me boima ba valve ea slide le khohlano e ea holimo, e bula koung ea ho kena le ho khutla ea valve ea liphallelo,' me oli e phalla. khutlela tanka. Ka mor'a hore valve ea li-slide e buloe, mokelikeli o tsamaisoa ke matla a hydraulic. E amehile, khatello ea P inlet e tla tsoela pele ho phahama, 'me valve ea slide e tla tsoela pele ho ea holimo. Ha matla a valve ea slide a leka-lekana sebakeng se itseng, khatello ea ho kena ea valve ea liphallelo e tla tsitsa ka boleng bo itseng, bo bitsoang khatello ea ho beha ea valve ea liphallelo.

4) Sefate sa ho monya oli: sebopeho sa ho itšeha ka ntle ho tanka, se kentsoe ka lehlakoreng la tanka ea oli ea hydraulic, tube e monyang oli e qoelisoa tlas'a boemo ba mokelikeli ka tankeng ea oli, 'me hlooho ea filthara ea filthara e pepesetsoa kantle. tanka ea oli; e na le valve ea ho itšeha, valve ea bypass, Karolo ea sefa e silafatsa transmitter le lisebelisoa tse ling. Ha u nkela sebaka kapa u hloekisa sefahla, se ka qhaqhoa 'me sa kenngoa ka ntle ho tanka. Ka mor'a hore karolo ea ho hloekisa e tlosoe, valve e itšehang e koala ka boeona ho thibela oli ho tsoa ka tanka. Bypass valve, ha sefahla se koalehile, mochini ha oa lokela ho koaloa hang-hang bakeng sa tlhokomelo. Oli e ka tsamaisoa ka valve ea bypass, 'me mochini o ka koaloa hore o hloekise kapa o nke sebaka sa sefahla ka nako e nepahetseng. Letšoao la phapang ea khatello ke sebopeho sa tlhahlobo ea pono ea mochini. Haeba sefahla se koalehile, se tla ama phapang ea khatello ea oli mme pointer e tla thekesela. , ha e supa sebaka se sefubelu, mochine o lokela ho koaloa bakeng sa ho hloekisa kapa ntho ea ho hloekisa e lokela ho nkeloa sebaka. Belofo ea bolo e kentsoe moo ho tsoang sefe ea sefe ho e koala nakong ea tokiso le tokiso ea phaephe ea haeteroliki ho thibela tahlehelo ea oli ka tankeng.

5) Filter ea oli e khutlisang: E na le valve ea bypass le sesupo sa phapang ea khatello. Sesefa se sefa litšila tse tiileng ka har'a oli ea haeteroliki, se thibela litšila tse ka har'a lipeipi ho kena ka tankeng, 'me se boloka oli ea sistimi e hloekile; valve ea bypass e sebelisoa ha karolo ea filthara e koalehile. Ka mor'a moo, ha hoa lumelloa ho koala mochine hang-hang bakeng sa tlhokomelo. Oli e ka tsamaisoa ka valve ea bypass, 'me mochine o lokela ho koaloa ho hloekisa kapa ho nkela karolo ea sefe ka nako e nepahetseng. Letšoao la phapang ea khatello ke mokhoa oa ho hlahloba pono ea mechine. Haeba karolo ea filthara e koalehile, e amang phapang ea khatello ea oli, qubu ea matšoao e a otlolla ebe e supa sebaka se sefubelu. Ha ho hlokahala, mochini o lokela ho koaloa ho hloekisa kapa ho nkela karolo ea sefa sebaka.

7) Moqomo oa oli o phahamisang: sebopeho sa moqomo oa oli oa mekhahlelo e meraro, se nang le valve ea throttle ea tsela e le 'ngoe; ho phahamisa le ho theola derrick, valve ea tsela e le 'ngoe ea throttle ho thibela matla a khoheli a fetelletseng nakong ea ts'ebetso ea ho thella ha derrick, le ho sireletsa polokeho ea ho phahamisa le ho thella ha derrick. Mochine ona o na le li-cylinders tse phahamisang habeli.

l Sebopeho le molao-motheo oa ho sebetsa: Sebopeho se na le cylinder, piston ea boemo ba pele, piston ea boemo ba bobeli, piston ea boemo ba boraro, lesale la tataiso, lesale la ho tiisa le likarolo tse ling. Hlooho ea silinda e na le letlapa la tsebe ea pin, e hokahaneng le poleiti e tsitsitseng ea tsebe holim'a sefate sa sefapano sa foreimi ka phini. Mokhahlelo oa boraro oa molamu oa piston o hokahane le pini ea lemati la derrick e tlase ka mokhoa o ts'oanang. Li-plungers tsa boemo ba pele le ba bobeli li na le mokhoa o le mong oa ts'ebetso. Tlas'a ketso ea oli ea hydraulic, plunger e tsoa ka matla 'me e hula ka boima ba eona ha e khutla. Piston ea boemo ba boraro e na le sebopeho sa liketso tse peli. Tlas'a ts'ebetso ea oli ea hydraulic, piston ea boemo ba boraro e matlafalitse katoloso le ho hula morao. Silinda e phahamisang e na le likou tse tharo tsa oli, P1, P2 le P3. Boema-kepe ba oli P1 bo hloohong ea silinda, bo hokelang phaposi ea ho sebetsa ea plunger le phaposi ea mothati oa boraro e se nang molamu. Ho na le valve ea tsela e le 'ngoe ea throttle phasejeng ea oli; boema-kepe ba oli P2 bo sebakeng sa boraro sa molamu oa piston, o hokahanyang phaposi ea mothati oa boraro e se nang molamu. Ho na le lesoba la throttle ka har'a molamu oa molamu le tselaneng ea oli; boema-kepe ba oli P3 bo boemong ba molamu oa piston ea mohato oa boraro, bo hokahanyang phaposi ea ho sebetsa ea plunger le phaposi ea mothati oa boraro e se nang melamu, 'me e hokahane le tsela ea oli ea P1. Ho na le lesoba la throttle phasejeng ea oli. Ho fanoa ka lesoba le kenang hloohong ea mothati oa boraro oa silindara ea piston ea silindara ea oli, 'me ho kentsoe plug e kenang ho eona.

l Ho ntša moea: Pele ho phahamisa le ho theoha ha derrick, moea o ka har'a silindara e phahamisang le cylinder ea telescopic o lokela ho tsoa ka botlalo. Oli ea Hydraulic e na le moea, 'me ho lutla ha lipeipi ho fella ka moea ka har'a silinda. Ha cylinder e phahamisang le cylinder ea telescopic li emisitsoe nako e telele, moea o tla bokellana karolong e ka holimo ea silinda. Ha derrick e phahamisoa le ho theoleloa, menyetla ea likotsi e tla eketseha, moea o tla tsoa, 'me likotsi tse patiloeng tsa likotsi li tla felisoa.

l Phallo ea moea ea liphaephe tsa tsamaiso: Bula belofo ea nale E holim'a phanele ea taolo ea li-valve tse kopantsoeng tse tšeletseng ho etsa potoloho e boreleli bakeng sa lisilindara tse phahamisang P1 le P3, ebe o hokela phala ea ho khutlisa oli. Phahamisa sephethephethe sa li-cylinder control valve, oli ea hydraulic ea pompo ea oli e kena ka silindara e phahamisang ka P1, ebe e khutlela tanka ea oli ka P3. Sisteme ea haeteroliki e sebetsa ntle le mojaro; Sisteme ea haeteroliki e tsamaea ntle le moroalo bakeng sa metsotso e 5 ho isa ho e 10, e felisa ho lutla ha pompong le khase ea silinda e phahamisang.

l Tlosa moea ho tswa ho molamu oa molamu oa piston ea mohato oa boraro oa moqomo o phahamisang: koala valve ea nale ea E, 'me li-cylinders tse phahamisang P1 le P3 li etsa potoloho e koetsoeng. Phahamisa hanyenyane letsoho la valve ea ho phahamisa li-cylinder, u fane ka oli ea khatello kamoreng e ka tlaase ea moqomo o phahamisang, laola khatello ea oli ho 2 ~ 3MPa, bula plug e tsoang mali karolong ea boraro ea piston cylinder head ea cylinder, 'me u e ntše. moea o ka moqomong o phahamisang.

l Tlhahlobo ea ho lutla ha sistimi: Phahamisa valve ea taolo ea cylinder hanyane, fana ka oli ea khatello kamoreng e tlase ea silinda e phahamisang, butle butle phahamisa derrick, tlohela 100 ~ 200mm hole le bracket e ka pele ea derrick, emisa ho phahamisa, 'me u boloke derrick. naheng ka metsotso e 5. Lekola sistimi ea hydraulic le liphaephe, ha hoa lokela ho ba le ho lutla kae kapa kae; hlokomela derrick, ha hoa lokela ho ba le moo e leng teng.

l Mokhoa oa tšireletso: Derrick e boima, 'me ho na le menyetla e mengata ea likotsi ha u phahamisa le ho theola derrick. Ela hloko haholoanyane nakong ea ts'ebetso 'me u latele ka tieo mekhoa ea ts'ebetso. Mekhoa e mengata ea tšireletso e behiloe bakeng sa moqomo o sireletsehileng oa ho phahamisa. Esita le haeba valve ea ho phahamisa li-cylinder e hlōleha kapa hose ea hydraulic e phunyehile 'me e senyehile, cylinder e phahamisang e tla fokotsa ka katleho lebelo la ho theola derrick le ho thibela likotsi tse kholo.

l Ho phahamisa derrick: Oli ea Hydraulic e kena ka kamoreng ea ho sebetsa ea cylinder ea oli ho tloha koung ea P1 ka valve ea tsela e le 'ngoe. Plunger ea boemo ba pele e fetela pele. Kamora ho fihla maemong, plunger ea boemo ba bobeli le molamu oa piston oa boemo ba boraro li atoloha ka tatellano. Piston ea boemo ba boraro e na le molamu. Oli e ka sekoting e khutla ka P2. Kaha sekepe sa P2 se na le lesoba le phunyeletsang, ha piston ea mohato oa boraro e atoloha, ho buloa ha valve ea taolo ho lokela ho fokotseha 'me lebelo la ho atolosa le lokela ho fokotseha. Ho seng joalo, khatello ea tsamaiso ea hydraulic e tla eketseha;

Theola derrick: Oli ea Hydraulic e kena ka har'a molamu oa molamu oa piston ea mohato oa boraro ho tloha P2, e sutumelletsa piston hore e hule. Oli e ka sekoting sa rodless e khutlela oli ka P1 throttle, 'me silinda e khutlela butle ho thibela matla a khoheli a feteletseng; Tatelano ea ho khutlisa ea plunger le piston e 'ngoe le e' ngoe ke: ea pele, piston ea mothati oa boraro e khutla. Ka mor'a ho fihla boemong boo, li-plungers tsa mohato oa bobeli le oa pele li khutlela morao ka tatellano. Ha li-plungers tsa bobeli le tsa mantlha li hula, li khutlela morao ka boima ba tsona ntle le ho fana ka oli ea haeteroliki ho silindara. Ka nako ena, lebelo la enjene le ka fokotsoa mme sebapi sa ts'ebetso se khutlela butle ho derrick.

8) Telescopic cylinder, hydraulic telescopic telescopic derrick ea mekato e 'meli.

l Sebopeho sa sebopeho: Silinda e telele ea plunger, e nang le bolelele ba cylinder ea 14 ho isa ho 16m. Ho na le boema-kepe ba oli qetellong ea plunger, 'me valve ea tsela e le' ngoe e kenngoa tseleng ea oli; hlooho ea cylinder e na le plug e tsoang mali. 'Mele oa cylinder oa oli o tlameletsoe karolong e ka holimo ea derrick ka liboutu tse bōpehileng joaloka U,' me holimo e hatelloa ka har'a selikalikoe sa setulo sa derrick beam. Karolo e ka tlase ea molamu oa plunger e na le poleiti e kopanyang, e kentsoeng ka lebaleng la 'mele o ka tlaase oa derrick.

l Mokhoa oa ho sebetsa. Derrick mokatong oa bobeli oa atolosoa, 'me valve ea taolo ea silindara ea oli ea telescopic e sebetsoa ho phahamisa. Oli ea khatello e kena ka har'a cylinder ka boema-kepe ba oli qetellong ea rod ea plunger, valve ea tsela e le 'ngoe, le plunger e sekoti, e sutumelletsa moqomo hore o atolohe, e khanna karolo e ka holimo ea derrick hore e phahame ka pina. Derrick e teng mme mochini oa phini oa ho notlela o notleloa ka bohona. Derrick ea mokatong oa bobeli e khutlisetsoa morao, 'me phini ea tšireletso e lokolloa ka letsoho. Ntlha ea pele, valve ea ho laola cylinder ea telescopic e sebelisoa ho phahamisa, e le hore derrick ea mokatong oa bobeli e phahame butle ka 200mm. Mochini oa ho notlela oa notlela oa notlolla ka bohona, ebe valve ea taolo ea telescopic cylinder e sebetsoa ho sutumelletsa fatše, 'me oli ea hydraulic e ka har'a cylinder ke Khatello e hlahisoang ke boima ba 'mele ea derrick ea mokato oa bobeli e phalla ka ntle ho cylinder ka throttle. kou le boema-kepe ba oli qetellong ea plunger. Derick ea mokato oa bobeli oa oa. Lebelo le oelang le lokisoa ke tekanyo ea ho bula ea valve ea tsela e le 'ngoe le valve ea telescopic cylinder control.

l Mochine oa polokeho: The derrick mokatong oa bobeli o boima ho feta, 'me ho na le menyetla e mengata ea likotsi ha u phahamisa le ho theola derrick. Ela hloko haholoanyane nakong ea ts'ebetso 'me u latele ka tieo mekhoa ea ts'ebetso. Silinda ea telescopic ea polokeho e na le valve ea tsela e le 'ngoe. Esita le haeba valve ea ho laola cylinder e hlōleha kapa hose ea hydraulic e phatlohile 'me e senyehile, silinda e tla fokotsa lebelo la ho theoha ha derrick le ho thibela likotsi tse kholo.

l Moea o tsoang: Ka mor'a hore cylinder e behoe nako e itseng, moea o tla kena ho tsoa ho tiiso. Silinda e sa tsoa kenngoa e na le moea o mongata ka hare. Ka hona, pele ho ts'ebetso e 'ngoe le e' ngoe ea cylinder ea telescopic, moea o ka har'a cylinder ea telescopic o tlameha ho lokolloa ho thibela ts'ebetso ea ho atolosa ha cylinder. Khasa. Phahamisa hanyenyane sets'oants'o sa "cylinder control valve", u fane ka oli ea khatello ho silinda ea telescopic, 'me u laole khatello ea oli ho 2 ho isa ho 3 MPa. Bula polaka e kenang ka holim'a silindara ho ntša moea ka har'a silindara ea telescopic. Ka mor'a ho ntša metsi, tiisa linate. U se ke ua sisinyeha ha u ntse u deflating. Bula latch ea tšireletso ea derrick.

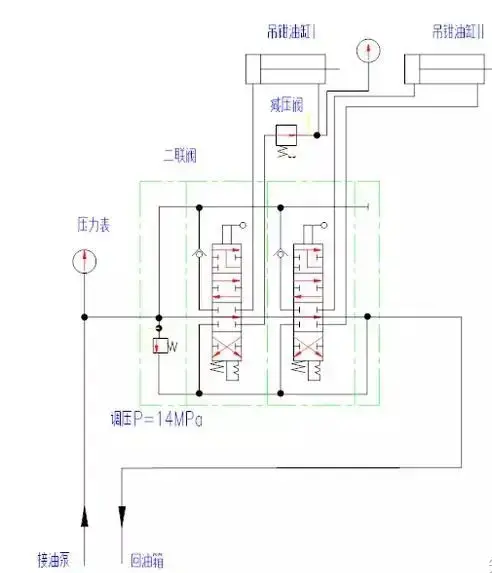

9) Clamp cylinder: Silinda e na le sebopeho sa piston ea litsela tse peli, 'me lisebelisoa tsa buffer li fanoa lipheletsong tse peli tsa hlooho ea cylinder le sekoahelo sa cylinder ho thibela tšusumetso ea hydraulic ea cylinder. Ha molamu oa piston oa moqomo oa oli o hohla, thapo ea hlooho ea katse ea tong e phahamisang e ea tiisoa ho tiisa le ho lokolla khoele ea ho phunya; molamu oa piston oa atoloha 'me thapo ea hlooho ea katse ea khutla.

10) Winch e nyane ea Hydraulic: mochini o fokotsang polanete, o nang le li-brake le valve ea ho leka-lekana, ho bolokehile ho phahamisa lintho mme o khona ho fofa moeeng.

11) Belofo e habeli: E kentsoe karolong e ka tlase ea lebokose la taolo ea mochini oa ho cheka, e na le poleiti ea valve e kenang ka oli, poleiti ea ho khutlisa oli le lipoleiti tse peli tsa valve tse sebetsang. Sekhechana sa valve ea ho kenya oli se na le valve ea polokeho ho fetola khatello e sebetsang e kenang ka valve e habeli. Lokolla le ho tiisa nate, 'me u sotha screw ea ho lokisa ho fetola khatello ea ho lokisa ea valve ea polokeho. Ha u ntse u phunyeletsa, khatello ea ho lokisa ea eketseha, 'me ha u senya, khatello ea ho lokisa e fokotseha. Hlokomela hore ka mor'a hore u lokisoe, tiisa sekoahelo se ka morao 'me u notlelle nut e lokisang. Plate ea valve e sebetsang e laoloa ka letsoho.

A. Ho phahamisa tong cylinder valve I: E laola silindara ea tong ea ho phahamisa hore e atolose le ho hohela morao hore e lokolle le ho tiisa thapo ea hlooho ea ankora. Mokotla oa valve o behiloe ka boemo ba valve e phaphametseng ho etsa potoloho ea silinda e fapaneng. Oli ea pompo ea oli le oli ea molamu oa molamu li kena ka sekoting se se nang rod sa cylinder ea oli ka nako e le 'ngoe, e leng se etsang hore molamu oa piston o atolohe kapele; valve core spring e khutla, e lokolle molamu, 'me mokokotlo oa valve o khutlela ka ho toba Boemong ba ho se nke lehlakore, motsamao oa silinda oa emisa.

B. Ho phahamisa tong cylinder valve II: E laola moqomo oa tong II oa ho phahamisa hore o atolose le ho khutlela morao ho lokolla le ho tiisa thapo ea hlooho ea ankora. Mokotla oa valve o behiloe ka boemo ba valve e phaphametseng ho etsa potoloho ea cylinder e fapaneng. Oli ea pompo ea oli le oli ea molamu oa molamu li kena ka har'a sekoti se se nang rod sa cylinder ea oli ka nako e le 'ngoe, e leng se etsang hore molamu oa piston o atolohe kapele; "valve core spring" e khutla, e lokolle molamu, 'me mokokotlo oa valve o khutlela ka ho toba Boemong ba ho se nke lehlakore, motsamao oa silinda oa emisa.

7) Moqomo oa oli o phahamisang: sebopeho sa moqomo oa oli oa mekhahlelo e meraro, se nang le valve ea throttle ea tsela e le 'ngoe; ho phahamisa le ho theola derrick, valve ea tsela e le 'ngoe ea throttle ho thibela matla a khoheli a fetelletseng nakong ea ts'ebetso ea ho thella ha derrick, le ho sireletsa polokeho ea ho phahamisa le ho thella ha derrick. Mochine ona o na le li-cylinders tse phahamisang habeli.

l Sebopeho le molao-motheo oa ho sebetsa: Sebopeho se na le cylinder, piston ea boemo ba pele, piston ea boemo ba bobeli, piston ea boemo ba boraro, lesale la tataiso, lesale la ho tiisa le likarolo tse ling. Hlooho ea silinda e na le letlapa la tsebe ea pin, e hokahaneng le poleiti e tsitsitseng ea tsebe holim'a sefate sa sefapano sa foreimi ka phini. Mokhahlelo oa boraro oa molamu oa piston o hokahane le pini ea lemati la derrick e tlase ka mokhoa o ts'oanang. Li-plungers tsa boemo ba pele le ba bobeli li na le mokhoa o le mong oa ts'ebetso. Tlas'a ketso ea oli ea hydraulic, plunger e tsoa ka matla 'me e hula ka boima ba eona ha e khutla. Piston ea boemo ba boraro e na le sebopeho sa liketso tse peli. Tlas'a ts'ebetso ea oli ea hydraulic, piston ea boemo ba boraro e matlafalitse katoloso le ho hula morao. Silinda e phahamisang e na le likou tse tharo tsa oli, P1, P2 le P3. Boema-kepe ba oli P1 bo hloohong ea silinda, bo hokelang phaposi ea ho sebetsa ea plunger le phaposi ea mothati oa boraro e se nang molamu. Ho na le valve ea tsela e le 'ngoe ea throttle phasejeng ea oli; boema-kepe ba oli P2 bo sebakeng sa boraro sa molamu oa piston, o hokahanyang phaposi ea mothati oa boraro e se nang molamu. Ho na le lesoba la throttle ka har'a molamu oa molamu le tselaneng ea oli; boema-kepe ba oli P3 bo boemong ba molamu oa piston ea mohato oa boraro, bo hokahanyang phaposi ea ho sebetsa ea plunger le phaposi ea mothati oa boraro e se nang melamu, 'me e hokahane le tsela ea oli ea P1. Ho na le lesoba la throttle phasejeng ea oli. Ho fanoa ka lesoba le kenang hloohong ea mothati oa boraro oa silindara ea piston ea silindara ea oli, 'me ho kentsoe plug e kenang ho eona.

l Ho ntša moea: Pele ho phahamisa le ho theoha ha derrick, moea o ka har'a silindara e phahamisang le cylinder ea telescopic o lokela ho tsoa ka botlalo. Oli ea Hydraulic e na le moea, 'me ho lutla ha lipeipi ho fella ka moea ka har'a silinda. Ha cylinder e phahamisang le cylinder ea telescopic li emisitsoe nako e telele, moea o tla bokellana karolong e ka holimo ea silinda. Ha derrick e phahamisoa le ho theoleloa, menyetla ea likotsi e tla eketseha, moea o tla tsoa, 'me likotsi tse patiloeng tsa likotsi li tla felisoa.

l Phallo ea moea ea liphaephe tsa tsamaiso: Bula belofo ea nale E holim'a phanele ea taolo ea li-valve tse kopantsoeng tse tšeletseng ho etsa potoloho e boreleli bakeng sa lisilindara tse phahamisang P1 le P3, ebe o hokela phala ea ho khutlisa oli. Phahamisa sephethephethe sa li-cylinder control valve, oli ea hydraulic ea pompo ea oli e kena ka silindara e phahamisang ka P1, ebe e khutlela tanka ea oli ka P3. Sisteme ea haeteroliki e sebetsa ntle le mojaro; Sisteme ea haeteroliki e tsamaea ntle le moroalo bakeng sa metsotso e 5 ho isa ho e 10, e felisa ho lutla ha pompong le khase ea silinda e phahamisang.

l Tlosa moea ho tswa ho molamu oa molamu oa piston ea mohato oa boraro oa moqomo o phahamisang: koala valve ea nale ea E, 'me li-cylinders tse phahamisang P1 le P3 li etsa potoloho e koetsoeng. Phahamisa hanyenyane letsoho la valve ea ho phahamisa li-cylinder, u fane ka oli ea khatello kamoreng e ka tlaase ea moqomo o phahamisang, laola khatello ea oli ho 2 ~ 3MPa, bula plug e tsoang mali karolong ea boraro ea piston cylinder head ea cylinder, 'me u e ntše. moea o ka moqomong o phahamisang.

l Tlhahlobo ea ho lutla ha sistimi: Phahamisa valve ea taolo ea cylinder hanyane, fana ka oli ea khatello kamoreng e tlase ea silinda e phahamisang, butle butle phahamisa derrick, tlohela 100 ~ 200mm hole le bracket e ka pele ea derrick, emisa ho phahamisa, 'me u boloke derrick. naheng ka metsotso e 5. Lekola sistimi ea hydraulic le liphaephe, ha hoa lokela ho ba le ho lutla kae kapa kae; hlokomela derrick, ha hoa lokela ho ba le moo e leng teng.

l Mokhoa oa tšireletso: Derrick e boima, 'me ho na le menyetla e mengata ea likotsi ha u phahamisa le ho theola derrick. Ela hloko haholoanyane nakong ea ts'ebetso 'me u latele ka tieo mekhoa ea ts'ebetso. Mekhoa e mengata ea tšireletso e behiloe bakeng sa moqomo o sireletsehileng oa ho phahamisa. Esita le haeba valve ea ho phahamisa li-cylinder e hlōleha kapa hose ea hydraulic e phunyehile 'me e senyehile, cylinder e phahamisang e tla fokotsa ka katleho lebelo la ho theola derrick le ho thibela likotsi tse kholo.

l Ho phahamisa derrick: Oli ea Hydraulic e kena ka kamoreng ea ho sebetsa ea cylinder ea oli ho tloha koung ea P1 ka valve ea tsela e le 'ngoe. Plunger ea boemo ba pele e fetela pele. Kamora ho fihla maemong, plunger ea boemo ba bobeli le molamu oa piston oa boemo ba boraro li atoloha ka tatellano. Piston ea boemo ba boraro e na le molamu. Oli e ka sekoting e khutla ka P2. Kaha sekepe sa P2 se na le lesoba le phunyeletsang, ha piston ea mohato oa boraro e atoloha, ho buloa ha valve ea taolo ho lokela ho fokotseha 'me lebelo la ho atolosa le lokela ho fokotseha. Ho seng joalo, khatello ea tsamaiso ea hydraulic e tla eketseha;

Theola derrick: Oli ea Hydraulic e kena ka har'a molamu oa molamu oa piston ea mohato oa boraro ho tloha P2, e sutumelletsa piston hore e hule. Oli e ka sekoting sa rodless e khutlela oli ka P1 throttle, 'me silinda e khutlela butle ho thibela matla a khoheli a feteletseng; Tatelano ea ho khutlisa ea plunger le piston e 'ngoe le e' ngoe ke: ea pele, piston ea mothati oa boraro e khutla. Ka mor'a ho fihla boemong boo, li-plungers tsa mohato oa bobeli le oa pele li khutlela morao ka tatellano. Ha li-plungers tsa bobeli le tsa mantlha li hula, li khutlela morao ka boima ba tsona ntle le ho fana ka oli ea haeteroliki ho silindara. Ka nako ena, lebelo la enjene le ka fokotsoa mme sebapi sa ts'ebetso se khutlela butle ho derrick.

8) Telescopic cylinder, hydraulic telescopic telescopic derrick ea mekato e 'meli.

l Sebopeho sa sebopeho: Silinda e telele ea plunger, e nang le bolelele ba cylinder ea 14 ho isa ho 16m. Ho na le boema-kepe ba oli qetellong ea plunger, 'me valve ea tsela e le' ngoe e kenngoa tseleng ea oli; hlooho ea cylinder e na le plug e tsoang mali. 'Mele oa cylinder oa oli o tlameletsoe karolong e ka holimo ea derrick ka liboutu tse bōpehileng joaloka U,' me holimo e hatelloa ka har'a selikalikoe sa setulo sa derrick beam. Karolo e ka tlase ea molamu oa plunger e na le poleiti e kopanyang, e kentsoeng ka lebaleng la 'mele o ka tlaase oa derrick.

l Mokhoa oa ho sebetsa. Derrick mokatong oa bobeli oa atolosoa, 'me valve ea taolo ea silindara ea oli ea telescopic e sebetsoa ho phahamisa. Oli ea khatello e kena ka har'a cylinder ka boema-kepe ba oli qetellong ea rod ea plunger, valve ea tsela e le 'ngoe, le plunger e sekoti, e sutumelletsa moqomo hore o atolohe, e khanna karolo e ka holimo ea derrick hore e phahame ka pina. Derrick e teng mme mochini oa phini oa ho notlela o notleloa ka bohona. Derrick ea mokatong oa bobeli e khutlisetsoa morao, 'me phini ea tšireletso e lokolloa ka letsoho. Ntlha ea pele, valve ea ho laola cylinder ea telescopic e sebelisoa ho phahamisa, e le hore derrick ea mokatong oa bobeli e phahame butle ka 200mm. Mochini oa ho notlela oa notlela oa notlolla ka bohona, ebe valve ea taolo ea telescopic cylinder e sebetsoa ho sutumelletsa fatše, 'me oli ea hydraulic e ka har'a cylinder ke Khatello e hlahisoang ke boima ba 'mele ea derrick ea mokato oa bobeli e phalla ka ntle ho cylinder ka throttle. kou le boema-kepe ba oli qetellong ea plunger. Derick ea mokato oa bobeli oa oa. Lebelo le oelang le lokisoa ke tekanyo ea ho bula ea valve ea tsela e le 'ngoe le valve ea telescopic cylinder control.

l Mochine oa polokeho: The derrick mokatong oa bobeli o boima ho feta, 'me ho na le menyetla e mengata ea likotsi ha u phahamisa le ho theola derrick. Ela hloko haholoanyane nakong ea ts'ebetso 'me u latele ka tieo mekhoa ea ts'ebetso. Silinda ea telescopic ea polokeho e na le valve ea tsela e le 'ngoe. Esita le haeba valve ea ho laola cylinder e hlōleha kapa hose ea hydraulic e phatlohile 'me e senyehile, silinda e tla fokotsa lebelo la ho theoha ha derrick le ho thibela likotsi tse kholo.

l Moea o tsoang: Ka mor'a hore cylinder e behoe nako e itseng, moea o tla kena ho tsoa ho tiiso. Silinda e sa tsoa kenngoa e na le moea o mongata ka hare. Ka hona, pele ho ts'ebetso e 'ngoe le e' ngoe ea cylinder ea telescopic, moea o ka har'a cylinder ea telescopic o tlameha ho lokolloa ho thibela ts'ebetso ea ho atolosa ha cylinder. Khasa. Phahamisa hanyenyane sets'oants'o sa "cylinder control valve", u fane ka oli ea khatello ho silinda ea telescopic, 'me u laole khatello ea oli ho 2 ho isa ho 3 MPa. Bula polaka e kenang ka holim'a silindara ho ntša moea ka har'a silindara ea telescopic. Ka mor'a ho ntša metsi, tiisa linate. U se ke ua sisinyeha ha u ntse u deflating. Bula latch ea tšireletso ea derrick.

9) Clamp cylinder: Silinda e na le sebopeho sa piston ea litsela tse peli, 'me lisebelisoa tsa buffer li fanoa lipheletsong tse peli tsa hlooho ea cylinder le sekoahelo sa cylinder ho thibela tšusumetso ea hydraulic ea cylinder. Ha molamu oa piston oa moqomo oa oli o hohla, thapo ea hlooho ea katse ea tong e phahamisang e ea tiisoa ho tiisa le ho lokolla khoele ea ho phunya; molamu oa piston oa atoloha 'me thapo ea hlooho ea katse ea khutla.

10) Winch e nyane ea Hydraulic: mochini o fokotsang polanete, o nang le li-brake le valve ea ho leka-lekana, ho bolokehile ho phahamisa lintho mme o khona ho fofa moeeng.

11) Belofo e habeli: E kentsoe karolong e ka tlase ea lebokose la taolo ea mochini oa ho cheka, e na le poleiti ea valve e kenang ka oli, poleiti ea ho khutlisa oli le lipoleiti tse peli tsa valve tse sebetsang. Sekhechana sa valve ea ho kenya oli se na le valve ea polokeho ho fetola khatello e sebetsang e kenang ka valve e habeli. Lokolla le ho tiisa nate, 'me u sotha screw ea ho lokisa ho fetola khatello ea ho lokisa ea valve ea polokeho. Ha u ntse u phunyeletsa, khatello ea ho lokisa ea eketseha, 'me ha u senya, khatello ea ho lokisa e fokotseha. Hlokomela hore ka mor'a hore u lokisoe, tiisa sekoahelo se ka morao 'me u notlelle nut e lokisang. Plate ea valve e sebetsang e laoloa ka letsoho.

A. Ho phahamisa tong cylinder valve I: E laola silindara ea tong ea ho phahamisa hore e atolose le ho hohela morao hore e lokolle le ho tiisa thapo ea hlooho ea ankora. Mokotla oa valve o behiloe ka boemo ba valve e phaphametseng ho etsa potoloho ea silinda e fapaneng. Oli ea pompo ea oli le oli ea molamu oa molamu li kena ka sekoting se se nang rod sa cylinder ea oli ka nako e le 'ngoe, e leng se etsang hore molamu oa piston o atolohe kapele; valve core spring e khutla, e lokolle molamu, 'me mokokotlo oa valve o khutlela ka ho toba Boemong ba ho se nke lehlakore, motsamao oa silinda oa emisa.

B. Ho phahamisa tong cylinder valve II: E laola moqomo oa tong II oa ho phahamisa hore o atolose le ho khutlela morao ho lokolla le ho tiisa thapo ea hlooho ea ankora. Mokotla oa valve o behiloe ka boemo ba valve e phaphametseng ho etsa potoloho ea cylinder e fapaneng. Oli ea pompo ea oli le oli ea molamu oa molamu li kena ka har'a sekoti se se nang rod sa cylinder ea oli ka nako e le 'ngoe, e leng se etsang hore molamu oa piston o atolohe kapele; "valve core spring" e khutla, e lokolle molamu, 'me mokokotlo oa valve o khutlela ka ho toba Boemong ba ho se nke lehlakore, motsamao oa silinda oa emisa.

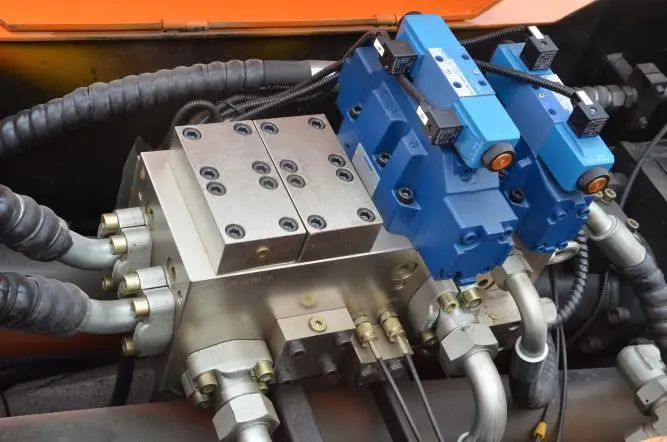

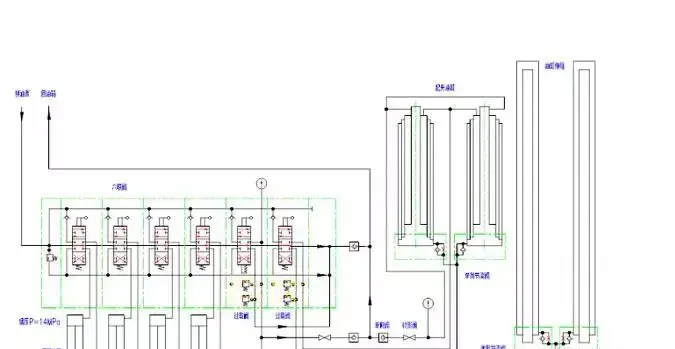

13) Kjaballo e tšeletseng e kopaneng: e kentsoe lebokoseng la taolo ea hydraulic ka lehlakoreng le ka morao la foreime. E na le poleiti ea oli ea letlapa, poleiti ea ho khutla ha oli le lipolanete tse tšeletseng tse sebetsang. Sekhechana sa oli se na le sekotoana sa polokeho ea polokeho ho fetola khatello e sebetsang ho kena ka valve e tšeletseng-le kopanya. Lokolla 'me u hlahlobe konopo ea ho fetola ho fetola khatello ea phetoho ea vala ea polokeho ea polokeho. Ha u ntse u tšolla, khatello ea ho fetola e ea eketseha, 'me ha u hlahloba, khatello ea ho lokisa e fokotseha. Hlokomela hore kamora ho fetoha, tiisa cap ea morao ebe u koala linate tsa ho fetola.

- Seqhubu sa silinda se ka pele ho le letona: se laola silindara e ka ntle ka pele ho foreime, se phahamisa le ho theola foreime, 'me se lokisa boemo ba foreimi. Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa.

- Phula e tsoang letsohong le letšehali la ho tloha letsohong le letšehali la chilinaer cylinda: Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa.

- Moralo o mong o tsoella ka morao oa khaba ea cylinder valve: Phahamisa, ho theola le ho beha sebopeho. Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa.

- Phula ea morao-rao e tsoang ka letsohong le letšehali la cylinda e khabisitsoeng. Phahamisa, ho theola le ho beha sebopeho. Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa.

- Ho phahamisa Volve ea Cylinder: ho laola mohato oa moqapi oa ho phahamisa moqapi oa ho phahamisa le ho theola moea ka kakaretso. Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa. Maeto a oli ka bobeli a entsoe ka li-valve tse pharalletseng ho fokotsa khatello ea ho kena silinda ea oli le ho ntlafatsa polokeho ea ts'ebetso ea Derrick.

- Volcopic oli ea silinda ea silinda ea leoatle: e laola ketso ea silinda ea oli ea telescopic e eketsang le ho khutlisa moea oa pale oa bobeli. Phini ea Valve Core Lock o behiloe 'me ho lokolloa. Sekhechana sa vala se ntse se lula boemong ba ho sebetsa le silila ea oli e ntse e tsoela pele. Maeto a oli ka bobeli a entsoe ka li-valve tse pharalletseng ho fokotsa khatello ea ho kena silinda ea oli le ho ntlafatsa polokeho ea ts'ebetso ea Derrick.

13) Kjaballo e tšeletseng e kopaneng: e kentsoe lebokoseng la taolo ea hydraulic ka lehlakoreng le ka morao la foreime. E na le poleiti ea oli ea letlapa, poleiti ea ho khutla ha oli le lipolanete tse tšeletseng tse sebetsang. Sekhechana sa oli se na le sekotoana sa polokeho ea polokeho ho fetola khatello e sebetsang ho kena ka valve e tšeletseng-le kopanya. Lokolla 'me u hlahlobe konopo ea ho fetola ho fetola khatello ea phetoho ea vala ea polokeho ea polokeho. Ha u ntse u tšolla, khatello ea ho fetola e ea eketseha, 'me ha u hlahloba, khatello ea ho lokisa e fokotseha. Hlokomela hore kamora ho fetoha, tiisa cap ea morao ebe u koala linate tsa ho fetola.

K. Front Overy Fripparger Volve: E laola sets'oants'o se kantle se ka pele ho foreime, 'me se fetola boemo ba foreimi. Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa.

B. Hlakileng sekoaelo se ka pele sa Cyligger Cylinder Valind Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa.

C. Morabeli o ka morao o tsoella-pele oa cylinder valve: Phahamisa, ho theola le ho beha sebopeho. Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa.

D. Ka morao ho leqele le letsopa la Letsoho la Drilinaer Volve: Laola mohloa o ka letsohong le letšehali ka morao foranteng. Phahamisa, ho theola le ho beha sebopeho. Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa.

E. Ho phahamisa Volve ea Cylinder: e laola ho sisinyeha ha moqapi oa ho phahamisa moqapi oa ho phahamisa le ho theola moea o akaretsang. Li-valve tsa valve li khutla, lokolla sethala, lilakane tsa valve li khutlela boemong bo sa nke lehlakore, 'me mokhatlo oa silinda oa emisa. Maeto a oli ka bobeli a entsoe ka li-valve tse pharalletseng ho fokotsa khatello ea ho kena silinda ea oli le ho ntlafatsa polokeho ea ts'ebetso ea Derrick.

F. TORSCICAIL VYLLER VYLLER: Ha e laolla ketso ea silinda ea oli ea telescopic ho holisa le ho khutlisa moea oa pale oa bobeli. Phini ea Valve Core Lock o behiloe 'me ho lokolloa. Sekhechana sa vala se ntse se lula boemong ba ho sebetsa le silila ea oli e ntse e tsoela pele. Maeto a oli ka bobeli a entsoe ka li-valve tse pharalletseng ho fokotsa khatello ea ho kena silinda ea oli le ho ntlafatsa polokeho ea ts'ebetso ea Derrick.

Matla a Hydraulic System

E na le likarolo tse latelang:

1) Pompo e tsamaeang e kenngoa motheong oa motlakase o hlobotseng sebakeng sa enjine. Enjene e potoloha 'me e khanna pompo ea oli ea ho sebetsa.

2) Filter ea auction ea oli e na le sebopeho se tsitsitseng kantle le tanka. E kentsoe lehlakoreng la tanka ea oli ea Hydraulic. Tube ea koloi ea oli e kenngoa ka tlasa boemo ba metsi ka tankeng ea oli. Hlooho ea filter e pepesoa kantle ho tanka ea oli. E na le valve ea ho ipataola, valves valves le ntho ea filthara. Ha o tlosa ntho e itseng ho hloekisa karolo ea lisebelisoa tsa lisebelisoa tse kang pakimiti ea tšilafalo, e ka etsoa kantle ho tanka. Ho bonolo ho hlakola le ho kenya, 'me oli ka tankeng e ke ke ea phalla.

3) Ho phatloha ho phatsimang le ho phallang ho fetola khatello ea sistimi, ho thibela ho uketts'a Sisteme, hape ho sireletsa polokeho ea sistimi le likarolo; Pompo ea oli e sebetsa ka lebelo le phahameng, 'me ha sekhahla sa ho phalla se le seholo haholo, phallo e khelohela tankeng ho netefatsa sekhahla se phallang se phahameng ka ho fetisisa sa sitise. Bona palo (phomolo le phallo e tsitsitseng ea valve)

4) Cheka e tsamaisang jale e latela tataiso ea lebili le tsamaeang, e tsamaisang oli ea hydraulic, e fana ka silinda ea ho tsamaisa le ho tjeka ka letsohong le letšehali ho tjeka ka letsohong le letšehali. Bona palo (vala ea speering e tsamaisang)

5) Sekhoni ba Tsamaiso, e leng Piston silinda e 'ngoe, e le' ngoe bakeng sa e 'ngoe le e' ngoe ea li-axles tse tharo tse ka pele; Hlooho ea Piston Rod e hokahane le letsoho la skickle ho laola tsela e nang le lebili. Bona setšoantšo (silinda cylinder)

- Vale ea bolo e hokahane pakeng tsa phaemoho le pompo ea oli ea oli. Ha rig ea ho cheka e sebetsa, bula phula ea bolo ho jarolla tsamaiso le ho sireletsa likarolo tsa sistimi.