Relief Valve-Cartridge Type

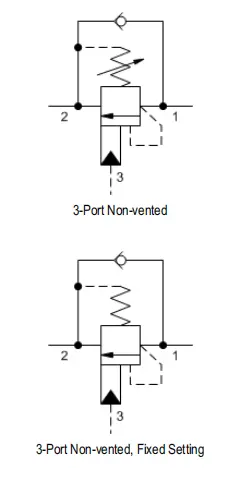

Counterbalance valves with pilot assist are meant to control an overrunning load. The check valve allows free flow

from the directional valve (port 2) to the load (port 1) while a direct-acting, pilot-assisted relief valve controls flow

from port 1 to port 2. Pilot assist at port 3 lowers the effective setting of the relief valve at a rate determined by the

pilot ratio.

TECHNICAL FEATURES

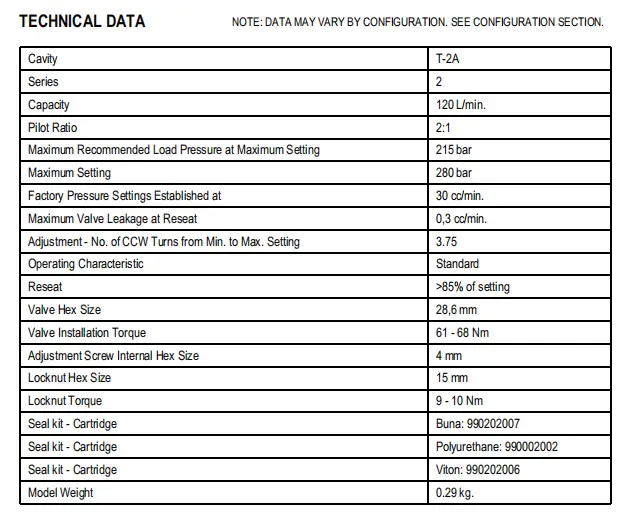

Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

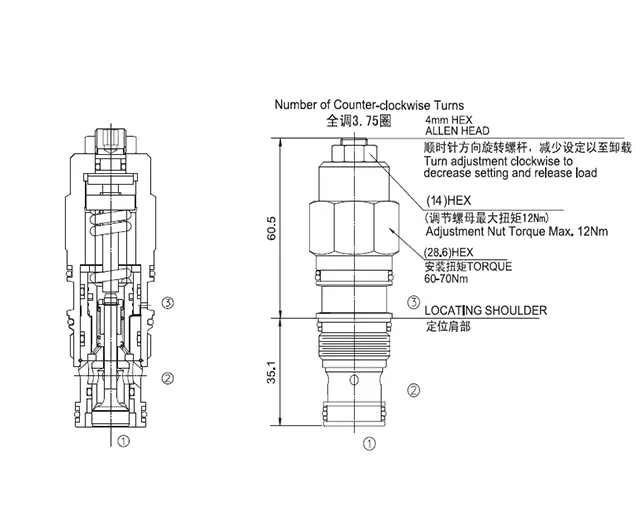

Turn adjustment clockwise to decrease setting and release load.

Full clockwise setting is less than 200 psi (14 bar).

Backpressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the backpressure.

Reseat exceeds 85% of set pressure when the valve is standard set. Settings lower than the standard set pressure may result in lower reseat percentages.

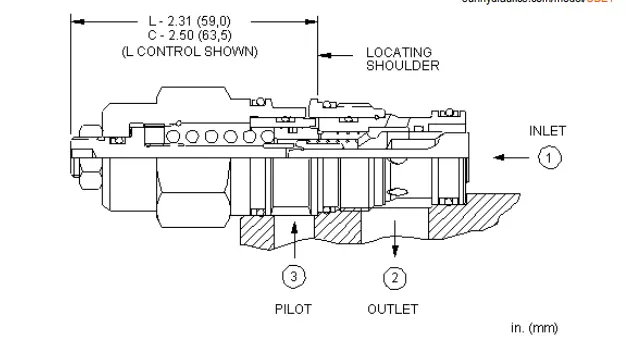

Sun counterbalance cartridges can be installed directly into a cavity machined in an actuator housing for added protection and improved stiffness in the circuit.

Two check valve cracking pressures are available. Use the 25 psi (1,7 bar) check unless actuator cavitation is a concern.

This valve uses orifices to lower the pilot ratio and therefore will pass up to 40 in³/min./1000 psi (0,7 L/min./70 bar) between port 2 and port 3. This is a consideration in master-slave circuits and in the leak testing of valve-cylinder assemblies.

All 3-port counterbalance, load control, and pilot-to-open check cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

OPERATION

Counterbalance valves with pilot assist are meant for control on overrunning load. The check valve allows free flow from port ② to port ① while a direct-acting, pilot-assisted relief valve controls flow from port ① to port ② . Pilot assist at port ③ lowers the effective setting of the relief valve at a rate determined by the pilot ratio.

FEATURES

1. Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

2. Backpressure at port ② adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the backpressure.

3. Reseat exceeds 85% of set pressure when the valve is standard set. Setting lower than the standard set pressure may result in lower reseat percentages.

4.Factory pressure setting established at 30cc/min(2 in3/min).

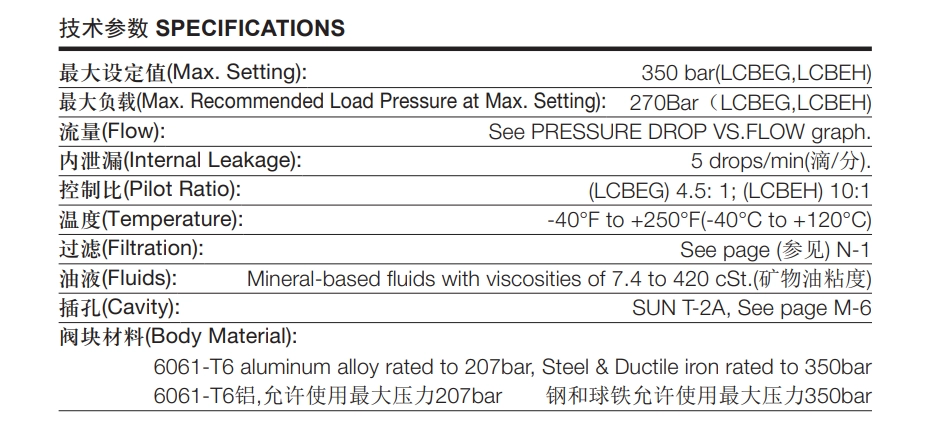

Technical characteristics

Work:

Balance valve with pilot opening is used to control overload conditions. The oil flows freely in one direction from port ② to port ①; the oil is directly driven, and the pilot auxiliary overflows from port ① to port ②. Port ③ is the overflow auxiliary control port, and the effective setting of the overflow function is reduced according to the control ratio value.

Characteristic:

1.The maximum set pressure is at least 1.3 times the maximum load pressure.

2.The back pressure at port ② is added to the setting value of the relief valve according to the multiple of "control ratio + 1", that is, the added value = (1 + control ratio) × pressure value.

3.At the standard setting, the closing pressure value is greater than 85% of the set pressure value; if it is lower than the standard setting, the percentage of the closing pressure value is reduced accordingly.

4.The factory setting refers to the pressure when the relief valve is open (flow rate is 30cc/min).