Mapangidwe oyambira ndi mfundo zogwirira ntchito za hydraulic system

2023-10-25一, mwachidule

Makina a hydraulic makamaka amaphatikiza pampu yayikulu yamafuta, tanki ya hydraulic, fyuluta, valavu yochepetsera kuthamanga, valavu yopumira, silinda yonyamula, silinda ya telescopic, silinda ya tong, silinda yakunja, ma hydraulic motor, ndi ntchito zosiyanasiyana zama hydraulic. ma valve ndi zigawo zina. Zidazi zisanachoke pafakitale, kupanikizika kwa valve yothandizira, valavu yochepetsera kupanikizika ndi ma valve osiyanasiyana opanikizika asinthidwa kuti atsimikizire kuti kayendedwe kabwino ka madzimadzi kakuyenda bwino, ndipo ogwiritsa ntchito saloledwa kuwasintha mofulumira panthawi yogwiritsira ntchito.

Dongosolo la hydraulic limaphatikizapo makina akuluakulu a hydraulic system ndi chiwongolero cha hydraulic system, ndipo machitidwe awiriwa amagawana tanki ya hydraulic.

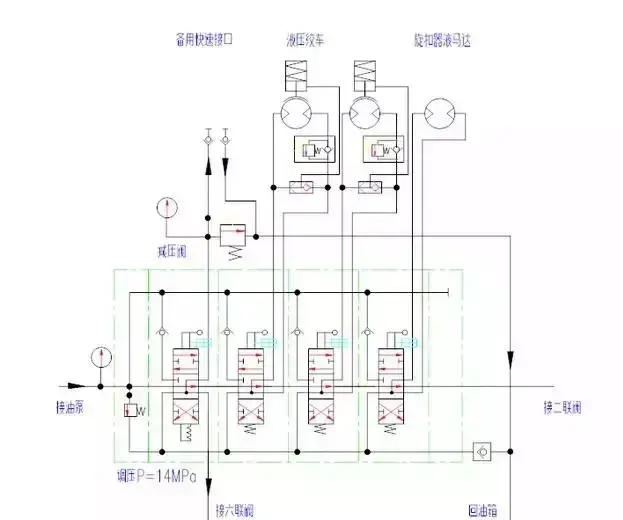

1.Main hydraulic system

Dongosolo lalikulu la hydraulic limapereka mphamvu ya hydraulic pobowola pobowola panthawi yokonza zida ndi kukonza kubowola. Ili ndi ma valve osiyanasiyana kuti azitha kuyendetsa bwino komanso kotetezeka pa chida chilichonse cha hydraulic.

2.Kusintha kwa hydraulic

Chiwongolero cha hydraulic system chimapereka mphamvu ya hydraulic ya hydraulic power chiwongolero cha kutsogolo kwagalimoto. Zili ndi ma valves osiyanasiyana kuti zithetse kupanikizika, kuyenda kwa kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake.

3.Makhalidwe apangidwe

The hydraulic system imakhala ndi:

¨ Main hydraulic system

¨ Chiwongolero cha hydraulic system

4.Main hydraulic system

Ili ndi zigawo zotsatirazi:

1) Thanki yamafuta a Hydraulic: masitolo, kuziziritsa, kutsitsa ndikusefa mafuta a hydraulic. Tanki yamafuta imayikidwa ndi:

l Pali zivundikiro ziwiri za maboo zomwe zimayikidwa pamwamba pa thanki yamafuta. Fyuluta ya mpweya wa hydraulic imayikidwa pa chivundikiro cha dzenje pamalo obwerera mafuta a thanki yamafuta;

l fyuluta ya mpweya wa Hydraulic, imasefa mpweya wodutsa mu thanki yamafuta, ndikusefa mafuta pamene thanki yamafuta iwonjezeredwa;

l Zoyezera zamadzimadzi, 2, zoyikidwa kutsogolo kwa thanki yamafuta. Pali milingo iwiri yamadzimadzi, yokwera ndi yotsika. Mlingo wapamwamba kwambiri wamadzimadzi umawonetsa mulingo wamafuta pambuyo potsitsa derrick; choyezera chamadzi otsika chamadzimadzi chikuwonetsa mulingo wamafuta pambuyo poti derrick idakhazikitsidwa;

l Choyezera kutentha kwamafuta chimayikidwa kutsogolo kwa thanki yamafuta kuti ayeze kutentha kwamafuta mu thanki. Kutentha kwamafuta abwinobwino kumakhala pakati pa 30 ndi 70 ° C. Pali madoko awiri akuluakulu obwerera mafuta, omwe amayikidwa pansi pa thanki yamafuta. Amakhala ndi ma valve a njira imodzi ndipo amalumikizidwa motsatana. Chitoliro chachikulu chobwezera mafuta ndi doko lobwezeretsa valavu; valavu yanjira imodzi imatseka yokha pokonza payipi ya hydraulic kuti mafuta asatayike mu thanki;

l Doko lotayira limayikidwa pansi pa thanki yamafuta ndikutsekedwa ndi pulagi; kutsegula pulagi kukhetsa thanki hayidiroliki mafuta;

l Doko loyamwa la mpope wamkulu wamafuta limayikidwa kutsogolo kwa thanki yamafuta, ndipo fyuluta yayikulu imayikidwa;

l Doko loyamwitsa pampu yamafuta limayikidwa kutsogolo kwa thanki yamafuta, ndipo fyuluta yowongolera mafuta imayikidwa;

l Doko lobwereranso lamafuta lachiwongolero limayikidwa pansi pa tanki yamafuta ndikukhala ndi valavu yanjira imodzi. Vavu yanjira imodzi imatseka yokha pokonza payipi ya hydraulic kuti mafuta asatayike mu thanki;

2) Pampu yamafuta a Hydraulic: Kapangidwe ka giya limodzi, mayunitsi 2, motsatana amayikidwa pamabokosi awiri otengera mphamvu ya hydraulic, yoyendetsedwa ndi gudumu la mpope la torque. Injini ikazungulira, bokosi lochotsa mphamvu limatha kuyendetsa pampu yamafuta. Bokosi lochotsa mphamvu lili ndi clutch ya hydraulic. Pamene hydraulic action ikufunika, chogwirira cha "liquid pump clutch" cha bokosi lowongolera la chobowola chimatha kugwiritsidwa ntchito ndikuyika "pampu yamafuta yomwe ndimatseka". Pampu yamafuta I imaphatikizidwa kuti ipange mafuta othamanga; chogwiriracho chimayikidwa "pampu yamafuta II". "Tsegulani" malo, pampu yamafuta II imalumikizidwa ndikutulutsa mafuta othamanga; Chogwiriracho chili m'malo osalowerera, ndipo mapampu onse amafuta amachotsa ndikuyimitsa.

3) Valavu yothandizira: mawonekedwe oyendetsa ndege, ma seti a 2, motsatana amayikidwa kumapeto kwa mafuta a pampu yayikulu yamafuta a hydraulic. Sinthani kuthamanga kwadongosolo, kupewa kuchulukira kwa dongosolo, ndikuteteza dongosolo ndi chitetezo chamagulu.

Mfundo yamapangidwe a valve yothandizira: Imapangidwa ndi valavu yoyendetsa ndege ndi valavu yayikulu. Gawo la valve yoyendetsa limaphatikizapo thupi la valve, valavu yowonongeka, kasupe woyendetsa kasupe ndi zina. Pali bowo laling'ono A pa valavu yayikulu ya slide, kuti mafuta othamangitsidwa ochokera kunja alowe m'chipinda chapamwamba B cha valavu ya slide. Pamene mphamvu ya hydraulic yomwe ikugwira pa valavu ya poppet ili yochepa kuposa mphamvu yowongolerera ya masika, valavu ya poppet valve yoyendetsa idzachita pansi pa mphamvu ya masika. Popeza palibe mafuta otuluka m'thupi la valve, kuthamanga kwa hydraulic m'zipinda zamafuta kumtunda ndi kumapeto kwa slide valve ndikofanana. Chifukwa chake, valavu ya slide ili pamalo owopsa a kumapeto kwapansi pansi pakuchita kwa masika akumtunda. Kulowetsa ndi kutuluka kwa valve yothandizira kumadulidwa ndi slide valve, ndipo valavu yothandizira sichimasefukira; pamene mphamvu ya hydraulic yomwe imagwira pa valve ya poppet ikukwera kuti ifanane ndi mphamvu ya masika chifukwa cha kuwonjezeka kwa kulowetsedwa kwa valve yothandizira, valve ya poppet imakankhidwa Tsegulani, mafuta omwe ali mu chipinda chapamwamba B cha slide valve amalowa mu mafuta. kutulukira kwa valavu kudzera pa doko lobwerera mafuta b ndi chapakati kudzera mu bowo la valavu, kenako kusefukira ku thanki yamafuta. Panthawiyi, mafuta oponderezedwa muzitsulo zamafuta a valve yothandizira amachokera ku bowo laling'ono a. Imawonjezeredwa mmwamba kupita ku chipinda B. Chifukwa pali kuchepa kwa mphamvu pamene mafuta akudutsa pabowo laling'ono A, kuthamanga kwa chipinda B kumakhala kotsika kusiyana ndi kuthamanga kwa mafuta olowera, ndipo kusiyana kwapakati kumawoneka pakati pa malekezero apamwamba ndi apansi. cha valve yosalala. Chifukwa chake, pansi pakuchitapo kanthu kwa kusiyana kwapakati pakati pa malekezero apamwamba ndi apansi, valavu ya slide imagonjetsa mphamvu ya masika, ndipo kulemera kwake kwa valavu ndi kukangana kwake kumasunthira mmwamba, kutsegula khomo lolowera ndi kubwerera kwa valve yothandizira, ndipo mafuta amayenda. kubwerera ku thanki. Pambuyo pa slide valve kutsegulidwa, madzimadzi amayendetsedwa ndi mphamvu ya hydraulic. Kukhudzidwa, kukakamiza kolowetsa P kudzapitirira kukwera, ndipo valavu ya slide idzapitirira kupita mmwamba. Pamene mphamvu ya slide valve imakhala yoyenera pa malo enaake, kulowetsedwa kwa valve yothandizira kudzakhazikika pamtengo wina, womwe umatchedwa kuyika kwa valve yothandizira.

4) Zosefera zoyamwa mafuta: mawonekedwe odzisindikiza okha kunja kwa thanki, yoyikidwa pambali pa thanki yamafuta a hydraulic, chubu choyamwa mafuta chimamizidwa pansi pamadzi mu thanki yamafuta, ndipo mutu wa fyuluta umawululidwa kunja kwa thanki yamafuta. thanki yamafuta; ili ndi valavu yodzisindikiza yokha, valavu yodutsa, Chosefera chimayipitsa chotumizira ndi zida zina. Mukasintha kapena kuyeretsa chosefera, chimatha kupasuka ndikuyika kunja kwa thanki. Choseferacho chikachotsedwa, valavu yodzisindikiza yokha imatseka kuti mafuta asatuluke mu thanki. Valavu yodutsa, pomwe chosefera chatsekedwa, makinawo sayenera kutsekedwa nthawi yomweyo kuti akonze. Mafuta amatha kuzunguliridwa kudzera pa valavu yodutsa, ndipo makinawo amatha kutsekedwa kuti ayeretse kapena kusintha zinthu zosefera panthawi yoyenera. Pressure kusiyana chizindikiro ndi makina owonera mawonekedwe. Ngati choseferacho chatsekedwa, chimakhudza kusiyana kwa kuthamanga kwa mafuta ndipo cholozera chidzagwedezeka. , ikaloza kudera lofiira, makinawo azitsekedwa kuti ayeretsedwe kapena kusintha zinthu zosefera. Valavu ya mpira imayikidwa potuluka fyuluta kuti itseke panthawi yokonza ndi kukonza payipi ya hydraulic kuti mafuta asatayike mu thanki.

5) Bweretsani fyuluta yamafuta: Yokhala ndi valavu yodutsa ndi chizindikiro chosiyana. Sefayi imasefa zonyansa zolimba mumafuta a hydraulic, imalepheretsa zonyansa zapaipi kulowa mu thanki, ndikusunga mafuta adongosolo; valve bypass imagwiritsidwa ntchito pamene fyuluta yatsekedwa. Pambuyo pake, sikuloledwa kutseka makinawo nthawi yomweyo kuti akonze. Mafuta amatha kuzunguliridwa kudzera mu valavu yodutsa, ndipo makinawo ayenera kutsekedwa kuti ayeretse kapena kusintha zinthu zosefera panthawi yoyenera. Chizindikiro cha kusiyana kwapanikiziro ndi mawonekedwe owonera makina. Ngati chosefera chatsekedwa, chomwe chimakhudza kusiyana kwa kuthamanga kwa mafuta, mulu wa chizindikiro umatambasula ndikulozera kudera lofiira. Pakafunika, makinawo azitsekedwa kuti ayeretse kapena kusintha zinthu zosefera.

7) Kukweza silinda yamafuta: magawo atatu ophatikizika a silinda yamafuta, okhala ndi valavu yanjira imodzi; kukweza ndi kutera derrick, valavu yanjira imodzi kuti mupewe mphamvu yokoka mopitilira muyeso pakutera kwa derrick, ndikuteteza chitetezo cha kukweza ndi kutera kwa derrick. Makinawa ali ndi masilinda onyamulira awiri.

l Kapangidwe ndi mfundo yogwirira ntchito: Kapangidwe kake kamakhala ndi silinda, pisitoni yoyamba, pisitoni yachiwiri, pisitoni yachitatu, mphete yolondolera, mphete yosindikizira ndi mbali zina. Mutu wa silinda uli ndi mbale ya khutu ya pini, yomwe imalumikizidwa ndi mbale yokhazikika pamakutu pamtengo wamtengo wapatali ndi pini. Ndodo ya pisitoni yachitatu imalumikizidwa ndi pini ya khomo la derrick m'munsi momwemo. Ma plungers a mlingo woyamba ndi wachiwiri ali ndi njira imodzi yochitira. Pansi pa mafuta a hydraulic, plunger imatuluka ndi mphamvu ndikubweza ndi kulemera kwake pobwerera. Pistoni yachitatu ili ndi njira ziwiri. Pansi pa mafuta a hydraulic, pisitoni yachitatu ya piston imathandizira kukulitsa ndikuchotsa. Silinda yonyamulira ili ndi madoko atatu amafuta, P1, P2 ndi P3. Doko lamafuta P1 lili pamutu wa silinda, kulumikiza chipinda chogwirira ntchito cha plunger ndi chipinda chopanda pisitoni chachitatu. Pali njira imodzi yopumira valavu mumsewu wamafuta; doko lamafuta P2 lili pagawo lachitatu pisitoni ndodo, kulumikiza chipinda chachitatu cha pisitoni chopanda rodless. Pali bowo lopumira mu ndodo ya ndodo ndi njira ya mafuta; doko lamafuta P3 lili pagawo lachitatu pisitoni ndodo, kulumikiza chipinda chogwirira ntchito cha plunger ndi chipinda chachitatu cha pisitoni yopanda ndodo, ndikulumikizana ndi gawo lamafuta la P1. Pali chiwopsezo chambiri mumsewu wamafuta. Bowo lotulukira limaperekedwa pamutu wa silinda ya pisitoni ya gawo lachitatu la silinda yamafuta, ndipo pulagi yolowera imayikidwapo.

l Kutulutsa mpweya: Musananyamule ndikutera kulikonse kwa derrick, mpweya mu silinda yonyamulira ndi silinda ya telescopic uyenera kutulutsidwa. Mafuta a Hydraulic amakhala ndi mpweya, ndipo kutayikira kwapaipi kumabweretsa mpweya mu silinda. Silinda yonyamula ndi telescopic cylinder ikayimitsidwa kwa nthawi yayitali, mpweya umachulukana kumtunda kwa silinda. Derrick ikakwezedwa ndikutsitsidwa, mwayi wa ngozi udzawonjezeka, mpweya udzatulutsidwa, ndipo zoopsa zobisika za ngozi zidzachotsedwa.

l Kutulutsa mpweya wamapaipi: Tsegulani valavu ya singano E pagawo lolumikizira ma valve asanu ndi limodzi kuti mupange kuzungulira kosalala kwa masilindala onyamulira P1 ndi P3, ndikulumikiza payipi yobwerera mafuta. Kwezani chogwirizira valavu yokweza silinda, mafuta a hydraulic a pampu yamafuta amalowa mu silinda yonyamula kudzera pa P1, kenako amabwerera ku tanki yamafuta kudzera pa P3. Dongosolo la hydraulic limayenda popanda katundu; hydraulic system imayenda popanda katundu kwa mphindi 5 mpaka 10, kuchotsa kutayikira mu payipi ndi mpweya wonyamula silinda.

l Tulutsani mpweya kuchokera pabowo la ndodo ya pisitoni yachitatu ya silinda yonyamula: kutseka valavu ya singano E, ndi masilindala okweza P1 ndi P3 amapanga dera lotsekedwa. Kwezani pang'ono chogwirira cha valavu yokweza ya silinda, perekani mafuta kuchipinda chotsika cha silinda yokweza, wongolerani kuthamanga kwamafuta pa 2 ~ 3MPa, tsegulani pulagi yotulutsa magazi pamutu wa silinda wa silinda wachitatu wa silinda, ndikutulutsa. mpweya mu silinda yonyamulira.

l Kuyang'anira kutayikira kwadongosolo: Kwezani pang'ono valavu yokweza silinda, perekani mafuta kuchipinda chotsika cha silinda yonyamulira, kwezani pang'onopang'ono derrick, siyani 100 ~ 200mm kutali ndi bulaketi yakutsogolo ya derrick, siyani kukweza, ndikusunga derrick. m'boma kwa mphindi 5. Yang'anani ma hydraulic system ndi mapaipi, pasakhale kutayikira kulikonse; onani derrick, pasakhale zodziwikiratu komwe ali.

l Njira yotetezera: Derrick ndi yolemetsa, ndipo pali mwayi waukulu wa ngozi pamene mukukweza ndi kutsitsa derrick. Samalani kwambiri panthawi yogwira ntchito ndikutsata ndondomeko zoyendetsera ntchito. Njira zingapo zotetezera zimakhazikitsidwa pa silinda yonyamula yotetezeka. Ngakhale valavu yokweza silinda ikalephera kapena payipi ya hydraulic ikuphwanyidwa ndikuwonongeka, silinda yokweza imachepetsa kuthamanga kwa derrick ndikuletsa ngozi zazikulu.

l Kukweza derrick: Mafuta a Hydraulic amalowa m'chipinda chogwirira ntchito cha silinda yamafuta kuchokera padoko la P1 kudzera pa valavu yanjira imodzi. Mphuno yamtundu woyamba imafalikira poyamba. Ikafika pamalopo, plunger yachiwiri ndi pisitoni ndodo yachitatu imafalikira motsatizana. Pistoni yamtundu wachitatu ili ndi ndodo. Mafuta omwe ali pabowo amabwerera kudzera mu P2. Popeza doko la P2 liri ndi dzenje lopukutira, pamene pisitoni yachitatu ikukwera, kutsegula kwa valve yolamulira kuyenera kuchepetsedwa ndipo liwiro lowonjezera liyenera kuchepetsedwa. Apo ayi, kupanikizika kwa hydraulic system kudzawonjezeka;

l Tsitsirani derrick: Mafuta a Hydraulic amalowa mu ndodo ya pisitoni yachitatu kuchokera ku P2, kukankhira pisitoni kuti ibweze. Mafuta omwe ali muzitsulo zopanda ndodo amabwerera ku mafuta kupyolera mu mpweya wa P1, ndipo silinda imabwerera pang'onopang'ono kuteteza mphamvu yokoka; Kubwereza kwa plunger ndi pistoni iliyonse ndi: choyamba, pisitoni yachitatu imabwereranso. Akafika pamalopo, oponya siteji yachiwiri ndi woyamba amabwerera motsatana. Pamene ma plungers achiwiri ndi oyambirira abwerera, amabwerera mmbuyo ndi kulemera kwawo popanda kupereka mafuta a hydraulic ku silinda. Panthawiyi, liwiro la injini likhoza kuchepetsedwa ndipo chogwiritsira ntchito chimabwerera pang'onopang'ono ku derrick.

8) Silinda ya telescopic, hydraulic telescopic yansanjika ziwiri derrick.

l Kapangidwe kake: Silinda yayitali yowonjezerapo, yokhala ndi kutalika kwa silinda 14 mpaka 16m. Pali doko lamafuta kumapeto kwa plunger, ndipo valavu yanjira imodzi imayikidwa munjira yamafuta; mutu wa silinda uli ndi pulagi yotulutsa magazi. Thupi la silinda yamafuta limamangiriridwa kumtunda wapamwamba wa derrick ndi ma bolt ooneka ngati U, ndipo pamwamba pake amakanikizidwa mu mphete ya mpando wa derrick beam. Pansi pa ndodo ya plunger imakhala ndi mbale yolumikizira, yomwe imamangidwira kumtengo wapansi pa thupi la derrick.

l Njira ya ntchito. Derrick pansanjika yachiwiri imakulitsidwa, ndipo valavu yowongolera ya silinda yamafuta ya telescopic imayendetsedwa kuti ikweze. Mafuta oponderezedwa amalowa mu silinda kudzera pa doko la mafuta kumapeto kwa ndodo ya plunger, valavu ya njira imodzi, ndi plunger yopanda kanthu, kukankhira silinda kuti italikitse, kuyendetsa kumtunda kwa derrick kukwera pamsewu. Derrick ili m'malo ndipo makina otsekera amadzitsekera okha. Derrick yansanjika yachiwiri imachotsedwa, ndipo pini yachitetezo imatulutsidwa pamanja. Choyamba, valavu yoyang'anira ma telescopic cylinder control valve imayendetsedwa kuti ikweze mmwamba, kotero kuti derrick yachiwiri ikukwera pang'onopang'ono pafupifupi 200mm. Pini yotsekera imatsegula yokha, ndiyeno valavu yowongolera ya telescopic cylinder imayendetsedwa kukankhira pansi, ndipo mafuta a hydraulic mu silinda ndi Kupanikizika komwe kumapangidwa ndi kudzilemera kwa derrick yachiwiri kumatuluka mu silinda kudzera pa throttle. doko ndi doko la mafuta kumapeto kwa plunger. Derrick wachiwiri akugwa. Liwiro lakugwa limasinthidwa ndi gawo lotsegulira la valavu yanjira imodzi ndi valavu yowongolera ma telescopic cylinder control.

l Njira yotetezera: Derrick pa chipinda chachiwiri ndi cholemera kwambiri, ndipo pali mwayi waukulu wa ngozi pamene mukukweza ndi kutsitsa derrick. Samalani kwambiri panthawi yogwira ntchito ndikutsata ndondomeko zoyendetsera ntchito. Silinda yachitetezo cha telescopic imakhala ndi valavu yanjira imodzi. Ngakhale valavu yowongolera silinda ikalephera kapena payipi ya hydraulic itasweka ndikuwonongeka, silindayo imatha kuchepetsa kuthamanga kwa derrick ndikuletsa ngozi zazikulu.

l Mpweya wotulutsa: Silinda ikayikidwa kwa nthawi yayitali, mpweya umalowa kuchokera pachisindikizocho. Silinda yomwe yakhazikitsidwa kumene imakhala ndi mpweya wambiri mkati. Choncho, isanayambe ntchito iliyonse ya telescopic yamphamvu, mpweya mu telescopic yamphamvu uyenera kutulutsidwa pofuna kupewa kukulitsa ndondomeko ya silinda. Kukwawa. Kwezani pang'ono chogwirira cha valavu yokweza silinda, perekani mafuta okakamiza ku silinda ya telescopic, ndikuwongolera kuthamanga kwamafuta pa 2 mpaka 3 MPa. Tsegulani pulagi yolowera pamwamba pa silinda kuti mutulutse mpweya mu silinda ya telescopic. Pambuyo kukhetsa, sungani mtedza. Osasuntha pamene mukupukuta. Tsegulani latch yachitetezo cha derrick.

9) Silinda ya clamp: Silinda ili ndi mawonekedwe a pisitoni anjira ziwiri, ndipo zida za buffer zimaperekedwa kumapeto kwa mutu wa silinda ndi chivundikiro cha silinda kuti zisawononge mphamvu ya hydraulic ya silinda. Ndodo ya pisitoni ya silinda yamafuta ikabwerera, chingwe chapamutu cha mphaka chonyamulira chimamangidwa kuti chikhwime ndi kumasula ulusi wobowola; ndodo ya pisitoni imatalika ndipo chingwe chamutu wa mphaka chimabwerera.

10) Winch yaying'ono ya Hydraulic: makina ochepetsera mapulaneti, okhala ndi ma brake and balance valve, ndi otetezeka kukweza zinthu ndipo amatha kuyenda mumlengalenga.

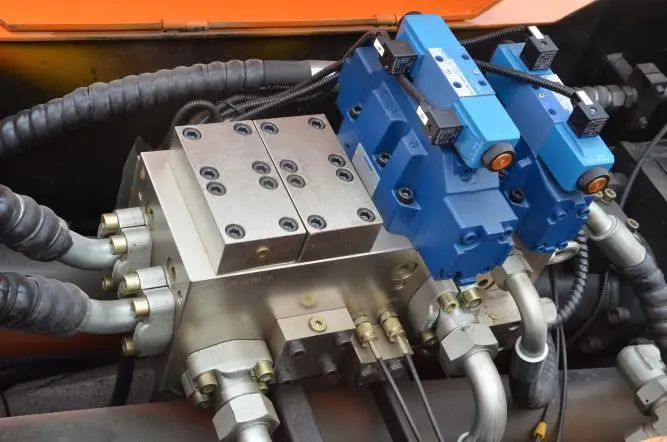

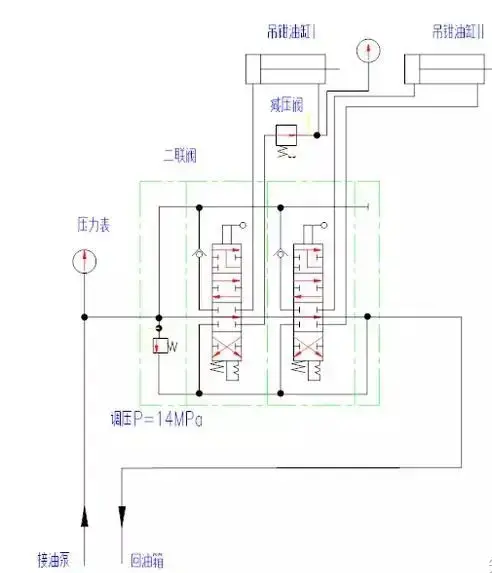

11) Valve iwiri: Yoyikidwa m'munsi mwa bokosi lowongolera la chobowola, imakhala ndi mbale yolowera mafuta, mbale yobwezeretsa mafuta ndi mbale ziwiri zogwirira ntchito. Chidutswa cha valve cholowetsa mafuta chimakhala ndi valavu yotetezera kuti isinthe kuthamanga kwa ntchito kulowa mu valve iwiri. Masulani ndi kumangitsa nati, ndi kupotoza wononga chosinthira kusintha kukakamiza kusintha kwa valavu chitetezo. Mukamalowa mkati, kupanikizika kosinthika kumawonjezeka, ndipo pamene mukutuluka, kupanikizika kumachepa. Zindikirani kuti mutatha kusintha, sungani kapu yakumbuyo ndikutseka nati yosinthira. Chovala cha valve chogwira ntchito chimayendetsedwa pamanja.

A. Vavu ya silinda ya tong I: Imawongolera silinda yokwezera tong I kuti italikitse ndi kubweza kuti imasuke ndi kumangitsa chingwe chamutu wa nangula. Choyambira cha valve chimayikidwa ndi valavu yoyandama kuti apange chozungulira cha silinda. Mafuta a pampu yamafuta ndi mafuta opangira ndodo amalowa m'bowo lopanda ndodo la silinda yamafuta nthawi yomweyo, zomwe zimapangitsa kuti ndodo ya pisitoni ikule mwachangu; valve core spring imabwerera, kumasula chogwirira, ndipo nsonga ya valve imabwereranso Pamalo osalowerera, kuyenda kwa silinda kumayima.

B. Kukweza valavu ya silinda II: Imawongolera silinda yokwezera tong II kuti italikitse ndi kubweza kumasula ndi kumangitsa chingwe chamutu wa nangula. Choyambira cha valve chimayikidwa ndi valavu yoyandama kuti apange chozungulira cha silinda. Mafuta a pampu yamafuta ndi mafuta opangira ndodo amalowa m'bowo lopanda ndodo la silinda yamafuta nthawi yomweyo, zomwe zimapangitsa kuti ndodo ya pisitoni ikule mwachangu; valve core spring imabwerera, kumasula chogwirira, ndipo nsonga ya valve imabwereranso Pamalo osalowerera, kuyenda kwa silinda kumayima.

7) Kukweza silinda yamafuta: magawo atatu ophatikizika a silinda yamafuta, okhala ndi valavu yanjira imodzi; kukweza ndi kutera derrick, valavu yanjira imodzi kuti mupewe mphamvu yokoka mopitilira muyeso pakutera kwa derrick, ndikuteteza chitetezo cha kukweza ndi kutera kwa derrick. Makinawa ali ndi masilinda onyamulira awiri.

l Kapangidwe ndi mfundo yogwirira ntchito: Kapangidwe kake kamakhala ndi silinda, pisitoni yoyamba, pisitoni yachiwiri, pisitoni yachitatu, mphete yolondolera, mphete yosindikizira ndi mbali zina. Mutu wa silinda uli ndi mbale ya khutu ya pini, yomwe imalumikizidwa ndi mbale yokhazikika pamakutu pamtengo wamtengo wapatali ndi pini. Ndodo ya pisitoni yachitatu imalumikizidwa ndi pini ya khomo la derrick m'munsi momwemo. Ma plungers a mlingo woyamba ndi wachiwiri ali ndi njira imodzi yochitira. Pansi pa mafuta a hydraulic, plunger imatuluka ndi mphamvu ndikubweza ndi kulemera kwake pobwerera. Pistoni yachitatu ili ndi njira ziwiri. Pansi pa mafuta a hydraulic, pisitoni yachitatu ya piston imathandizira kukulitsa ndikuchotsa. Silinda yonyamulira ili ndi madoko atatu amafuta, P1, P2 ndi P3. Doko lamafuta P1 lili pamutu wa silinda, kulumikiza chipinda chogwirira ntchito cha plunger ndi chipinda chopanda pisitoni chachitatu. Pali njira imodzi yopumira valavu mumsewu wamafuta; doko lamafuta P2 lili pagawo lachitatu pisitoni ndodo, kulumikiza chipinda chachitatu cha pisitoni chopanda rodless. Pali bowo lopumira mu ndodo ya ndodo ndi njira ya mafuta; doko lamafuta P3 lili pagawo lachitatu pisitoni ndodo, kulumikiza chipinda chogwirira ntchito cha plunger ndi chipinda chachitatu cha pisitoni yopanda ndodo, ndikulumikizana ndi gawo lamafuta la P1. Pali chiwopsezo chambiri mumsewu wamafuta. Bowo lotulukira limaperekedwa pamutu wa silinda ya pisitoni ya gawo lachitatu la silinda yamafuta, ndipo pulagi yolowera imayikidwapo.

l Kutulutsa mpweya: Musananyamule ndikutera kulikonse kwa derrick, mpweya mu silinda yonyamulira ndi silinda ya telescopic uyenera kutulutsidwa. Mafuta a Hydraulic amakhala ndi mpweya, ndipo kutayikira kwapaipi kumabweretsa mpweya mu silinda. Silinda yonyamula ndi telescopic cylinder ikayimitsidwa kwa nthawi yayitali, mpweya umachulukana kumtunda kwa silinda. Derrick ikakwezedwa ndikutsitsidwa, mwayi wa ngozi udzawonjezeka, mpweya udzatulutsidwa, ndipo zoopsa zobisika za ngozi zidzachotsedwa.

l Kutulutsa mpweya wamapaipi: Tsegulani valavu ya singano E pagawo lolumikizira ma valve asanu ndi limodzi kuti mupange kuzungulira kosalala kwa masilindala onyamulira P1 ndi P3, ndikulumikiza payipi yobwerera mafuta. Kwezani chogwirizira valavu yokweza silinda, mafuta a hydraulic a pampu yamafuta amalowa mu silinda yonyamula kudzera pa P1, kenako amabwerera ku tanki yamafuta kudzera pa P3. Dongosolo la hydraulic limayenda popanda katundu; hydraulic system imayenda popanda katundu kwa mphindi 5 mpaka 10, kuchotsa kutayikira mu payipi ndi mpweya wonyamula silinda.

l Tulutsani mpweya kuchokera pabowo la ndodo ya pisitoni yachitatu ya silinda yonyamula: kutseka valavu ya singano E, ndi masilindala okweza P1 ndi P3 amapanga dera lotsekedwa. Kwezani pang'ono chogwirira cha valavu yokweza ya silinda, perekani mafuta kuchipinda chotsika cha silinda yokweza, wongolerani kuthamanga kwamafuta pa 2 ~ 3MPa, tsegulani pulagi yotulutsa magazi pamutu wa silinda wa silinda wachitatu wa silinda, ndikutulutsa. mpweya mu silinda yonyamulira.

l Kuyang'anira kutayikira kwadongosolo: Kwezani pang'ono valavu yokweza silinda, perekani mafuta kuchipinda chotsika cha silinda yonyamulira, kwezani pang'onopang'ono derrick, siyani 100 ~ 200mm kutali ndi bulaketi yakutsogolo ya derrick, siyani kukweza, ndikusunga derrick. m'boma kwa mphindi 5. Yang'anani ma hydraulic system ndi mapaipi, pasakhale kutayikira kulikonse; onani derrick, pasakhale zodziwikiratu komwe ali.

l Njira yotetezera: Derrick ndi yolemetsa, ndipo pali mwayi waukulu wa ngozi pamene mukukweza ndi kutsitsa derrick. Samalani kwambiri panthawi yogwira ntchito ndikutsata ndondomeko zoyendetsera ntchito. Njira zingapo zotetezera zimakhazikitsidwa pa silinda yonyamula yotetezeka. Ngakhale valavu yokweza silinda ikalephera kapena payipi ya hydraulic ikuphwanyidwa ndikuwonongeka, silinda yokweza imachepetsa kuthamanga kwa derrick ndikuletsa ngozi zazikulu.

l Kukweza derrick: Mafuta a Hydraulic amalowa m'chipinda chogwirira ntchito cha silinda yamafuta kuchokera padoko la P1 kudzera pa valavu yanjira imodzi. Mphuno yamtundu woyamba imafalikira poyamba. Ikafika pamalopo, plunger yachiwiri ndi pisitoni ndodo yachitatu imafalikira motsatizana. Pistoni yamtundu wachitatu ili ndi ndodo. Mafuta omwe ali pabowo amabwerera kudzera mu P2. Popeza doko la P2 liri ndi dzenje lopukutira, pamene pisitoni yachitatu ikukwera, kutsegula kwa valve yolamulira kuyenera kuchepetsedwa ndipo liwiro lowonjezera liyenera kuchepetsedwa. Apo ayi, kupanikizika kwa hydraulic system kudzawonjezeka;

l Tsitsirani derrick: Mafuta a Hydraulic amalowa mu ndodo ya pisitoni yachitatu kuchokera ku P2, kukankhira pisitoni kuti ibweze. Mafuta omwe ali muzitsulo zopanda ndodo amabwerera ku mafuta kupyolera mu mpweya wa P1, ndipo silinda imabwerera pang'onopang'ono kuteteza mphamvu yokoka; Kubwereza kwa plunger ndi pistoni iliyonse ndi: choyamba, pisitoni yachitatu imabwereranso. Akafika pamalopo, oponya siteji yachiwiri ndi woyamba amabwerera motsatana. Pamene ma plungers achiwiri ndi oyambirira abwerera, amabwerera mmbuyo ndi kulemera kwawo popanda kupereka mafuta a hydraulic ku silinda. Panthawiyi, liwiro la injini likhoza kuchepetsedwa ndipo chogwiritsira ntchito chimabwerera pang'onopang'ono ku derrick.

8) Silinda ya telescopic, hydraulic telescopic yansanjika ziwiri derrick.

l Kapangidwe kake: Silinda yayitali yowonjezerapo, yokhala ndi kutalika kwa silinda 14 mpaka 16m. Pali doko lamafuta kumapeto kwa plunger, ndipo valavu yanjira imodzi imayikidwa munjira yamafuta; mutu wa silinda uli ndi pulagi yotulutsa magazi. Thupi la silinda yamafuta limamangiriridwa kumtunda wapamwamba wa derrick ndi ma bolt ooneka ngati U, ndipo pamwamba pake amakanikizidwa mu mphete ya mpando wa derrick beam. Pansi pa ndodo ya plunger imakhala ndi mbale yolumikizira, yomwe imamangidwira kumtengo wapansi pa thupi la derrick.

l Njira ya ntchito. Derrick pansanjika yachiwiri imakulitsidwa, ndipo valavu yowongolera ya silinda yamafuta ya telescopic imayendetsedwa kuti ikweze. Mafuta oponderezedwa amalowa mu silinda kudzera pa doko la mafuta kumapeto kwa ndodo ya plunger, valavu ya njira imodzi, ndi plunger yopanda kanthu, kukankhira silinda kuti italikitse, kuyendetsa kumtunda kwa derrick kukwera pamsewu. Derrick ili m'malo ndipo makina otsekera amadzitsekera okha. Derrick yansanjika yachiwiri imachotsedwa, ndipo pini yachitetezo imatulutsidwa pamanja. Choyamba, valavu yoyang'anira ma telescopic cylinder control valve imayendetsedwa kuti ikweze mmwamba, kotero kuti derrick yachiwiri ikukwera pang'onopang'ono pafupifupi 200mm. Pini yotsekera imatsegula yokha, ndiyeno valavu yowongolera ya telescopic cylinder imayendetsedwa kukankhira pansi, ndipo mafuta a hydraulic mu silinda ndi Kupanikizika komwe kumapangidwa ndi kudzilemera kwa derrick yachiwiri kumatuluka mu silinda kudzera pa throttle. doko ndi doko la mafuta kumapeto kwa plunger. Derrick wachiwiri akugwa. Liwiro lakugwa limasinthidwa ndi gawo lotsegulira la valavu yanjira imodzi ndi valavu yowongolera ma telescopic cylinder control.

l Njira yotetezera: Derrick pa chipinda chachiwiri ndi cholemera kwambiri, ndipo pali mwayi waukulu wa ngozi pamene mukukweza ndi kutsitsa derrick. Samalani kwambiri panthawi yogwira ntchito ndikutsata ndondomeko zoyendetsera ntchito. Silinda yachitetezo cha telescopic imakhala ndi valavu yanjira imodzi. Ngakhale valavu yowongolera silinda ikalephera kapena payipi ya hydraulic itasweka ndikuwonongeka, silindayo imatha kuchepetsa kuthamanga kwa derrick ndikuletsa ngozi zazikulu.

l Mpweya wotulutsa: Silinda ikayikidwa kwa nthawi yayitali, mpweya umalowa kuchokera pachisindikizocho. Silinda yomwe yakhazikitsidwa kumene imakhala ndi mpweya wambiri mkati. Choncho, isanayambe ntchito iliyonse ya telescopic yamphamvu, mpweya mu telescopic yamphamvu uyenera kutulutsidwa pofuna kupewa kukulitsa ndondomeko ya silinda. Kukwawa. Kwezani pang'ono chogwirira cha valavu yokweza silinda, perekani mafuta okakamiza ku silinda ya telescopic, ndikuwongolera kuthamanga kwamafuta pa 2 mpaka 3 MPa. Tsegulani pulagi yolowera pamwamba pa silinda kuti mutulutse mpweya mu silinda ya telescopic. Pambuyo kukhetsa, sungani mtedza. Osasuntha pamene mukupukuta. Tsegulani latch yachitetezo cha derrick.

9) Silinda ya clamp: Silinda ili ndi mawonekedwe a pisitoni anjira ziwiri, ndipo zida za buffer zimaperekedwa kumapeto kwa mutu wa silinda ndi chivundikiro cha silinda kuti zisawononge mphamvu ya hydraulic ya silinda. Ndodo ya pisitoni ya silinda yamafuta ikabwerera, chingwe chapamutu cha mphaka chonyamulira chimamangidwa kuti chikhwime ndi kumasula ulusi wobowola; ndodo ya pisitoni imatalika ndipo chingwe chamutu wa mphaka chimabwerera.

10) Winch yaying'ono ya Hydraulic: makina ochepetsera mapulaneti, okhala ndi ma brake and balance valve, ndi otetezeka kukweza zinthu ndipo amatha kuyenda mumlengalenga.

11) Valve iwiri: Yoyikidwa m'munsi mwa bokosi lowongolera la chobowola, imakhala ndi mbale yolowera mafuta, mbale yobwezeretsa mafuta ndi mbale ziwiri zogwirira ntchito. Chidutswa cha valve cholowetsa mafuta chimakhala ndi valavu yotetezera kuti isinthe kuthamanga kwa ntchito kulowa mu valve iwiri. Masulani ndi kumangitsa nati, ndi kupotoza wononga chosinthira kusintha kukakamiza kusintha kwa valavu chitetezo. Mukamalowa mkati, kupanikizika kosinthika kumawonjezeka, ndipo pamene mukutuluka, kupanikizika kumachepa. Zindikirani kuti mutatha kusintha, sungani kapu yakumbuyo ndikutseka nati yosinthira. Chovala cha valve chogwira ntchito chimayendetsedwa pamanja.

A. Vavu ya silinda ya tong I: Imawongolera silinda yokwezera tong I kuti italikitse ndi kubweza kuti imasuke ndi kumangitsa chingwe chamutu wa nangula. Choyambira cha valve chimayikidwa ndi valavu yoyandama kuti apange chozungulira cha silinda. Mafuta a pampu yamafuta ndi mafuta opangira ndodo amalowa m'bowo lopanda ndodo la silinda yamafuta nthawi yomweyo, zomwe zimapangitsa kuti ndodo ya pisitoni ikule mwachangu; valve core spring imabwerera, kumasula chogwirira, ndipo nsonga ya valve imabwereranso Pamalo osalowerera, kuyenda kwa silinda kumayima.

B. Kukweza valavu ya silinda II: Imawongolera silinda yokwezera tong II kuti italikitse ndi kubweza kumasula ndi kumangitsa chingwe chamutu wa nangula. Choyambira cha valve chimayikidwa ndi valavu yoyandama kuti apange chozungulira cha silinda. Mafuta a pampu yamafuta ndi mafuta opangira ndodo amalowa m'bowo lopanda ndodo la silinda yamafuta nthawi yomweyo, zomwe zimapangitsa kuti ndodo ya pisitoni ikule mwachangu; valve core spring imabwerera, kumasula chogwirira, ndipo nsonga ya valve imabwereranso Pamalo osalowerera, kuyenda kwa silinda kumayima.

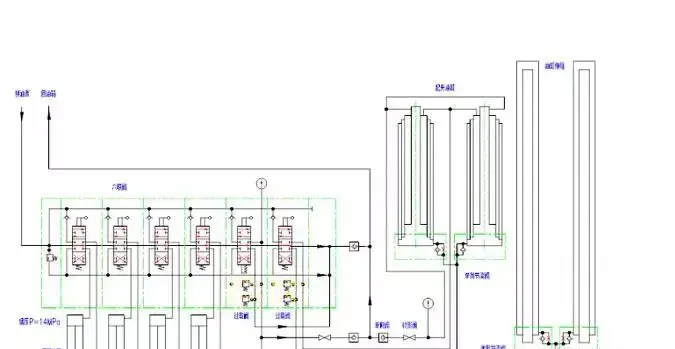

13) Valavu zisanu ndi chimodzi: zokhazikitsidwa pa bokosi la Hydraulic lowongolera kumbuyo kwa chimango. Ili ndi mbale yophika mafuta, vumba yobwezera mafuta ndi mbale zisanu ndi chimodzi zogwirira ntchito. Chidutswa cha mafuta ophika mafuta chimakhala ndi valavu yotetezera kuti musinthe kukakamiza kuyika valavu ya limodzi. Amamasula ndikulimba mtedza, ndikupotoza screw kuti asinthe kukakamizidwa kwa valavu ya chitetezo. Mukamata, kuthamanga kwa kupanikizika kumawonjezeka, ndipo potuluka, kupanikizika komwe kumachepa. Dziwani kuti pambuyo posintha, mangitsani kapu yakumbuyo ndikutseka nati.

- Vavu ya silinda yakutsogolo yakumanja: imayang'anira silinda yakumanja yakutsogolo kwa chimango, imakweza ndikutsitsa chimango, ndikusintha mulingo wa chimango. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima.

- Kutsogolo kwa ma cliver verve: kumawongolera silinda lamanzere kutsogolo kwa chimango, chimakweza ndikuchepetsa chimango, ndikusintha mulingo wa chimango. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima.

- Kumbuyo kwa Cylinder Valve: kumawongolera silinda yoyenera kumbuyo kwa chimango. Kwezani, otsika ndi mulingo. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima.

- Kumbuyo kwa Cylinder Valve: kumawongolera silinda komwe kumachokera kumbuyo kwa chimango. Kwezani, otsika ndi mulingo. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima.

- Kukweza Cylinder Vaveve: kumawongolera kayendedwe kanu kaninda kuti akweze ndi kutsitsa derrick. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima. Madoko onse otulutsa mafuta ali ndi mavesi ochulukirapo kuti achepetse kukakamiza komwe akulowetsa sing'anga yamafuta ndikusintha chitetezo cha derrick opareshoni.

- Telescopic mafuta cylinder valavu yama Valescopic mafuta okulitsa ndikuthamangitsanso nkhani yachiwiri. Chikhomo cha valavu yokhotakhotakhota ndi chogwirizira chimamasulidwa. Valavuyo imangokhalabe pogwira ntchito ndipo silinda wamafuta limapitilizabe kuyenda. Madoko onse otulutsa mafuta ali ndi mavesi ochulukirapo kuti achepetse kukakamiza komwe akulowetsa sing'anga yamafuta ndikusintha chitetezo cha derrick opareshoni.

13) Valavu zisanu ndi chimodzi: zokhazikitsidwa pa bokosi la Hydraulic lowongolera kumbuyo kwa chimango. Ili ndi mbale yophika mafuta, vumba yobwezera mafuta ndi mbale zisanu ndi chimodzi zogwirira ntchito. Chidutswa cha mafuta ophika mafuta chimakhala ndi valavu yotetezera kuti musinthe kukakamiza kuyika valavu ya limodzi. Amamasula ndikulimba mtedza, ndikupotoza screw kuti asinthe kukakamizidwa kwa valavu ya chitetezo. Mukamata, kuthamanga kwa kupanikizika kumawonjezeka, ndipo potuluka, kupanikizika komwe kumachepa. Dziwani kuti pambuyo posintha, mangitsani kapu yakumbuyo ndikutseka nati.

A. Front Countger Speve Valve: imayendetsa silinda yoyenera kutsogolo kwa chimango, ndikukweza chimango, ndikusintha mulingo wa chimango. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima.

B. Front Kumanzere Valve Valve: imayendetsa silinda yomwe yakumanzere kutsogolo kwa chimango, ndikukweza chimango, ndikusintha mulingo wa chimango. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima.

C. Kumbuyo kwa Cylinder Valve: imayendetsa silinda yoyenera kumbuyo kwa chimango. Kwezani, otsika ndi mulingo. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima.

D. Kumbuyo kumanzere Varve: kumawongolera silini kumanzere kumbuyo kwa chimango. Kwezani, otsika ndi mulingo. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima.

E. Kukweza Cylinder Valve: kumawongolera kayendedwe kanu kaninda kuti akweze ndi kutsitsa derrick. Valavu pachipata cha masika amabwerera, kumasula chogwiriracho, valavu imangobwerera ku malo osalowerera ndale, ndipo ma cylinder kayendedwe kaima. Madoko onse otulutsa mafuta ali ndi mavesi ochulukirapo kuti achepetse kukakamiza komwe akulowetsa sing'anga yamafuta ndikusintha chitetezo cha derrick opareshoni.

F. Telescopic Mafuta a Clinder Valve: imawongolera zochita za stalescopic mafuta slinder kuti mufikire ndikuchotsa nkhani yachiwiri. Chikhomo cha valavu yokhotakhotakhota ndi chogwirizira chimamasulidwa. Valavuyo imangokhalabe pogwira ntchito ndipo silinda wamafuta limapitilizabe kuyenda. Madoko onse otulutsa mafuta ali ndi mavesi ochulukirapo kuti achepetse kukakamiza komwe akulowetsa sing'anga yamafuta ndikusintha chitetezo cha derrick opareshoni.

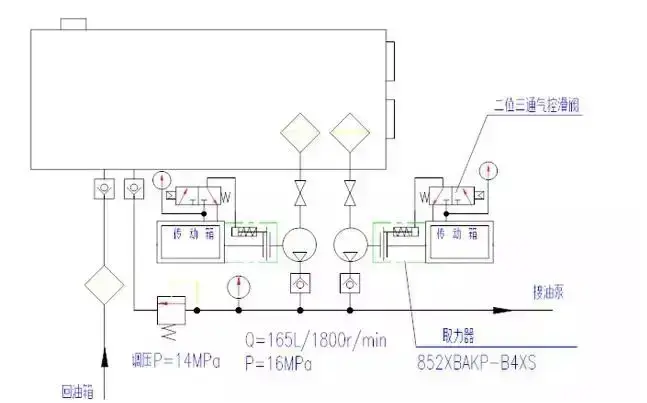

2.Kusintha kwa hydraulic

Ili ndi zigawo zotsatirazi:

1) Pampu yamafuta yamagetsi imayikidwa padoko la injini la injini. Injini imazungulira ndikuyendetsa pampu yamafuta kuti igwire ntchito.

2) Fyuluta yoikika yamafuta imakhala ndi mawonekedwe odzikonda kunja kwa thankiyo. Imakhazikitsidwa kumbali ya thanki yamafuta a hydraulic. Chubu chonyowa mafuta amamizidwa pansi pa madzi mu thanki yamafuta. Mutu wa fyuluta umawululidwa kunja kwa thanki yamafuta. Imakhala ndi valavu yodzipewera, valavu ya Byvess ndi fyuluta. Mukasinthanitsa kapena kuyeretsa zosefera za zida monga zida zosokoneza bongo, zitha kuchitika kunja kwa thankiyo. Ndiosavuta kusokoneza ndikukhazikitsa, ndipo mafuta mu thanki satuluka.

3) Kuchulukitsa kwamphamvu ndikuyenda kumasintha dongosolo, kumalepheretsa kuchuluka kwa dongosolo, ndikuteteza chitetezo cha dongosolo ndi zigawo zikuluzikulu; Pampu yamafuta imagwira ntchito kuthamanga kwambiri, ndipo nthawi yoyenda imakhala yayikulu kwambiri, kutuluka kumasoketsedwa ku tank kuti mutsimikizire kuti dongosolo la dongosolo la dongosololi. Onani chithunzi (mpumulo ndi kupumula valavu)

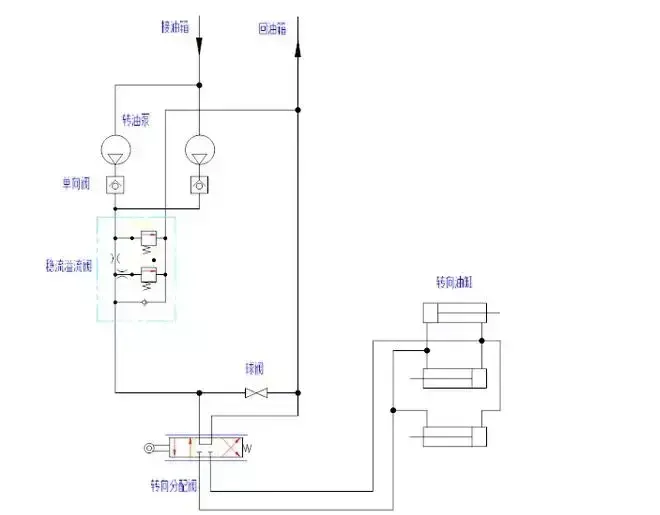

4) Vewa logawa litsatire chiwongolero cha chiwongolero, chimayendetsa njira yoyenda ndi mafuta a hydraulic, imapereka mawilo am'tsogolo, ndikukankhira mawilo a axle kuti atembenukire kumanzere ndi kumanja. Onani chithunzi (valavu yogawana)

5) Kuwongolera masilinda, sisinji ya piston, imodzi ya ma axles atatu kutsogolo; Mutu wa piston rod umalumikizidwa ndi chiwongolero chomangika kuti muwongolere gudumu. Onani chithunzi (chiwongolero chowongolera)

- Valove valavu imalumikizidwa pakati pa mapaipi opanikizika ndi mapaipi a mafuta. Pamene rig yobowola ikugwira ntchito, tsegulani valavu ya mpira kuti mutsitse dongosolo ndikuteteza zigawo zikuluzikulu.