Unleashing the Power: Your Ultimate Guide to Hydraulic Monoblock Control Valves

2025-02-24Are you ready to dive deep into the world of hydraulic power? This comprehensive guide will illuminate the critical role of the monoblock control valve, often referred to as a monoblock valve, in a hydraulic system. We'll explore its design, applications, and advantages over other control valves. Whether you're a machinery manufacturer, a hydraulic system integrator, or simply curious about the technology that makes modern equipment run, this article is for you. We'll break down complex concepts into easily digestible information, providing you with the knowledge to make informed decisions about your hydraulic needs. Discover how these robust hydraulic components help manage hydraulic power, making the hydraulic system run smoothly. This article is worth reading because it will provide a detailed overview of monoblock control valves, explaining how these vital components function within hydraulic systems, their diverse applications, and why they're a cornerstone of efficiency and reliability in numerous industries.

What Exactly is a Hydraulic Monoblock Valve and How Does it Work?

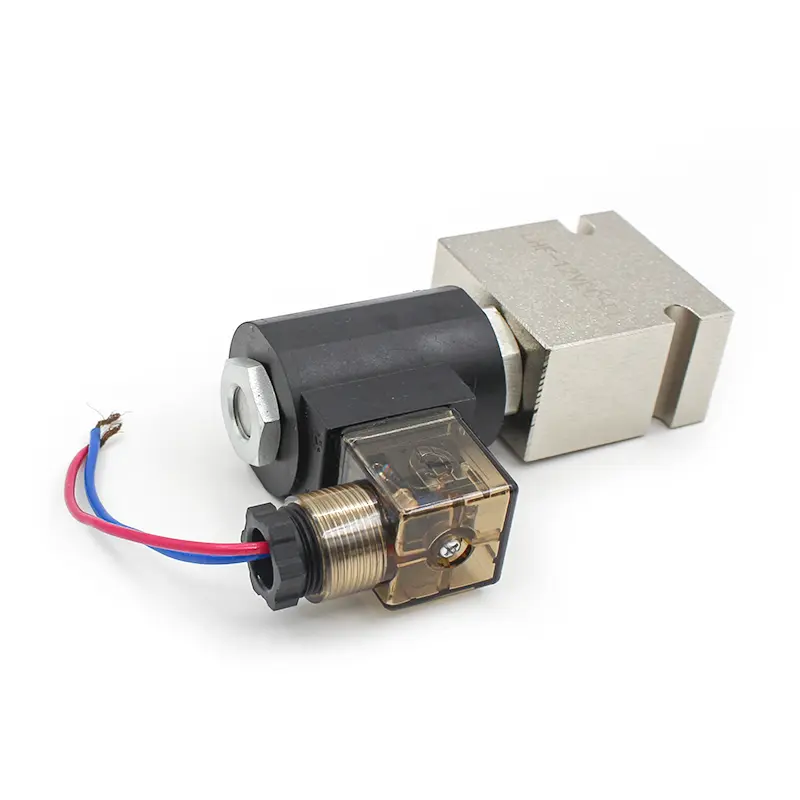

A monoblock valve, or monoblock directional control valve, is a single, integrated unit designed to control the flow and direction of hydraulic fluid within a hydraulic system. Unlike sectional valves, which are built from multiple stacked sections, a monoblock is a solid valve block. This design makes them particularly robust and well-suited for heavy-duty applications.

Inside the valve body, a spool moves to open and close ports, which allows hydraulic fluid to flow in different directions. The spool's position, determined by the control mechanism, dictates the path the fluid takes, thus controlling the movement of hydraulic motors or cylinders. The efficiency of this process is a key factor for any hydraulic system.

What are the Key Advantages of a Monoblock Control Valve?

Monoblock valves offer several advantages over other valve types. Their integrated design simplifies installation and reduces the potential for leaks, a critical factor in any hydraulic system. Also the solid valve body contributes to the overall durability and structural integrity, making them ideal for harsh environments.

Monoblock designs also tend to be more cost-effective than their sectional counterparts, especially for applications requiring a limited number of functions. They often provide high efficiency because they can handle the flow rate in your hydraulic system and the direct control of fluid flow. These benefits help many hydraulic operations.

What are the Different Types of Monoblock Control Valves and Their Applications?

The valve type will depend on the specifics of the hydraulic system in your machinery. Monoblock control valves come in various configurations. They can feature different spool arrangements to control the direction of fluid flow to match the demands of the hydraulic circuit. They are often found in construction equipment, agricultural machinery like tractors and harvesters, and other industrial applications.

You might find monoblock directional control valve in the following:

- Manual control valves: Operated directly by a lever or handle.

- Pneumatic control valves: Controlled by air pressure.

- Valves with various ports: Different port configurations, depending on the application.

How Do I Select the Right Monoblock Valve for My Hydraulic System?

Choosing the right monoblock valve depends on several factors, including the hydraulic system's pressure and flow requirements. Another factor to consider is the number of sections, or functions, needed to control the hydraulic components. Think about the desired flow rate, the type of hydraulic fluid used, and the port sizes required for the hydraulic lines.

Assess what control method is most appropriate, and hydraulic and electro-hydraulic control are very common in modern hydraulic systems. Take into account whether your machinery requires flow control for different movements. Evaluate your needs to make sure to ensure the valve will be used correctly.

What are the Different Spool Configurations and Their Control Functions?

The spool is the core of the monoblock control valve, responsible for directing the flow of hydraulic fluid. The spool design determines the control direction and the function the valve will perform. Common spool configurations include:

- 3-position spools: Offer three distinct positions, providing more precise control.

- 2-position spools: Offer two positions, for simpler on/off or directional control.

- Closed-center spools: Block hydraulic fluid in all positions, useful for holding loads.

The spool’s arrangement will help control the movement and functionality of different parts of the hydraulic system. The choice will influence the control of the flow and direction of hydraulic fluid in your system.

What is the Importance of a Relief Valve in a Hydraulic System?

A relief valve, such as a relief valve-cartridge type found on our site, is a crucial safety component in any hydraulic system. Its primary function is to protect the system from overpressure, which can damage components like hydraulic pumps and cylinders. When the pressure exceeds a set limit, the relief valve opens to divert hydraulic fluid back to the reservoir, preventing a dangerous buildup.

It is critical for the safety and longevity of the hydraulic equipment and the hydraulic system. A relief valve helps control the pressure within the hydraulic system to safeguard all the hydraulic components used.

How do Monoblock Control Valves Differ From Sectional Valves?

While both monoblock and sectional control valves serve the same basic purpose – to control the flow and direction of hydraulic fluid – their design and applications differ significantly. Monoblock valves are designed as a single solid block, which makes them simpler, sturdier, and less prone to leaks. They are often easier to install and more cost-effective for simple hydraulic systems.

Sectional valves, on the other hand, are built from multiple sections that can be added or removed to customize the valve's functionality. This modular design offers greater flexibility for complex applications requiring many hydraulic functions. However, sectional valves can have sectional leak points, potentially compromising the system's performance and reliability. The selection will be between monoblock and sectional solutions.

What are the Common Causes of Monoblock Valve Failure and How Can They Be Prevented?

Proper maintenance is essential to prolong the life of a monoblock valve. Common causes of failure include contamination of the hydraulic fluid, excessive pressure, and wear of internal components like spools and seals. To prevent failures:

- Use a high-quality hydraulic fluid and filter it regularly.

- Adhere to the hydraulic system's recommended pressure limits.

- Inspect the valve for leaks and unusual noises.

- Replace seals and other wear parts as needed.

Implementing a proactive maintenance schedule will help to ensure the valve is in working order and to prevent costly downtime and repairs. Regular checkups will extend the life of your monoblock control valves and improve the efficiency of your hydraulic operations.

What are the Common Control Methods Used with Monoblock Valves?

Monoblock control valves offer various operation methods including manual control, where a lever or handle directs the spool's position. They may also use pneumatic control using air pressure to control the spool. More advanced systems can incorporate hydraulic and electro-hydraulic control, which provides more complex and automated control of the system. You can select these methods according to your needs, this will have a direct impact on how the control of hydraulic will occur.

The control of hydraulic is usually achieved by control valves have many outstanding features. Some valves have fixed and big pull to allow for easier control direction and performance. Depending on the control of hydraulic, some systems use an easy pull rod to control the direction.

Where Can I Find High-Quality Monoblock Control Valves?

For reliable monoblock valves, consider a reputable supplier with a proven track record, like Allen from China. Look for manufacturers that adhere to international standards and offer a wide range of products to suit your specific needs. Prioritize suppliers that offer excellent customer service and technical support. You can find this at Bost Hydraulic, which is known for their commitment to quality and their extensive selection of hydraulic components. Purchasing monoblock valves for your application can be a simple process.

Remember the following important points:

- Monoblock valves offer simple, rugged, and typically cost-effective control for hydraulic systems.

- Select the correct monoblock valve based on pressure, flow, and required functions, taking into account different valve type.

- Proper maintenance, including clean hydraulic fluid and regular inspections, is critical to preventing failures.

- Consider different control methods like manual control and pneumatic control, and electro-hydraulic control to fit your application's needs.

- Look for a trusted supplier that provides high-quality products, technical support, and competitive pricing.

By understanding these key aspects of hydraulic monoblock control valves, you are better equipped to select, maintain, and leverage these critical components for optimal performance in your hydraulic systems. Ready to buy new hydraulic components? Explore more options, or consult with a specialist, and make an informed decision. If you're looking for a reliable source, explore the Double Pilot Operated Check Valves or Direct Acting Sequence Valves for additional valves.