Understanding the Three Categories of Hydraulic Control Valves

2024-10-29Welcome to the DELAITE blog! As a leading manufacturer and supplier of hydraulic components, we know how essential hydraulic control valves are for various applications in industries such as manufacturing, construction, and automotive. In this post, we’ll explore the three main categories of hydraulic control valves, helping you understand their functions and applications.

What Are Hydraulic Control Valves?

Hydraulic control valves are devices used to control the flow and pressure of hydraulic fluids within a system. They play a crucial role in directing fluid to various components, ensuring optimal performance and efficiency. Understanding the different categories of hydraulic control valves can help you choose the right one for your specific needs.

The Three Categories of Hydraulic Control Valves

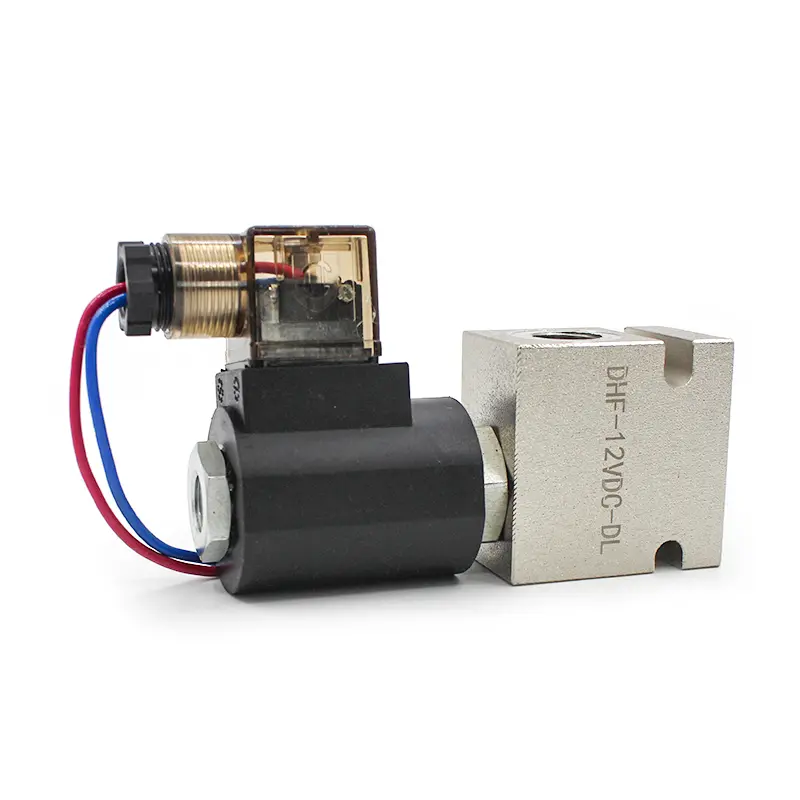

1. Directional Control Valves

Directional control valves are designed to control the path of the hydraulic fluid within the system. They determine the direction in which the fluid flows, allowing operators to control the movement of hydraulic actuators such as cylinders and motors.

• Types: Common types include spool valves, poppet valves, and rotary valves.

• Applications: Used in applications where precise movement control is required, such as in hydraulic presses, forklifts, and excavators.

At DELAITE, we offer a range of high-quality directional control valves that ensure reliable operation and durability in demanding environments.

2. Pressure Control Valves

Pressure control valves are essential for maintaining the desired pressure levels within a hydraulic system. They prevent system overloads and protect components from damage by regulating the pressure of the hydraulic fluid.

• Types: Key types include relief valves, pressure-reducing valves, and sequence valves.

• Applications: Commonly used in systems that require pressure regulation, such as hydraulic lifts, agricultural machinery, and industrial equipment.

Our pressure control valves at DELAITE are designed to provide accurate pressure control, ensuring the safety and efficiency of your hydraulic systems.

3. Flow Control Valves

Flow control valves manage the flow rate of hydraulic fluid within a system. By adjusting the flow, these valves help control the speed of hydraulic actuators, allowing for smooth and precise operation.

• Types: Includes needle valves, throttle valves, and flow control cartridges.

• Applications: Used in applications where flow regulation is critical, such as in hydraulic motors, conveyor systems, and injection molding machines.

At DELAITE, our flow control valves are engineered for optimal performance, providing you with the control you need for your hydraulic applications.

Why Choose DELAITE?

At DELAITE, we are committed to providing high-quality hydraulic components that meet the needs of various industries. Here’s why you should choose us:

• Quality Assurance: Our products are manufactured to the highest standards, ensuring reliability and performance in every application.

• Expert Guidance: Our knowledgeable team is here to help you select the right hydraulic control valves for your specific requirements.

• Customer Satisfaction: We prioritize your satisfaction and strive to deliver exceptional service with every order.

Conclusion

Understanding the three categories of hydraulic control valves—directional control valves, pressure control valves, and flow control valves—can help you make informed decisions for your hydraulic systems. By choosing the right valves, you can enhance the efficiency and safety of your operations.

If you’re looking for high-quality hydraulic control valves and components, look no further than DELAITE. Contact us today to learn more about our products and how we can support your hydraulic needs!