The function and working principle of hydraulic balancing valve

2024-02-06Hydraulic Balance Valve is a very important hydraulic component. Its function is to achieve precise control in the hydraulic system, maintain the balance of the hydraulic system and solve complex control problems.

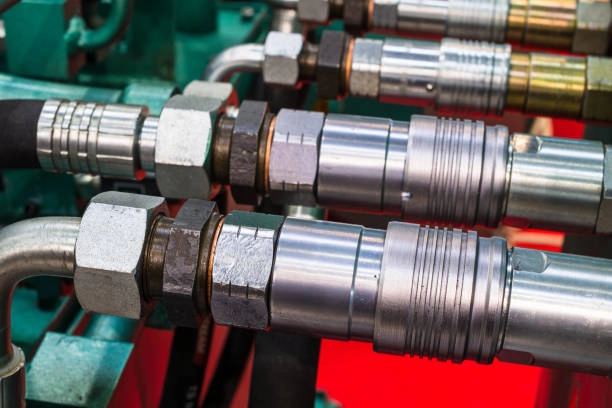

Hydraulic balance valve is a high-efficiency and reliable hydraulic component. It has the advantages of high working pressure, high precision, and high power. It is widely used in construction machinery, excavating machinery, bulldozing machinery, tractor machinery, petroleum machinery and other fields.

The working principle of the hydraulic balance valve is that in the hydraulic system, when the hydraulic fluid flows to the piston where the balance valve is installed, the piston inside the balance valve will be adjusted by the internal pressure, so that the pressure is transmitted from outside the stroke to within the stroke, making the hydraulic system Achieve balance. When the pressure exceeds the maximum value set by the balance valve, the hydraulic flow will overflow, keeping the hydraulic system at a safe operating level.

The main functions of the hydraulic balance valve are:

1.In addition to the dynamic load on the piston and piston rod, the piston can work continuously and the movement error of the piston rod can be reduced to a minimum.

2.Control the piston stroke as needed so that the piston can be controlled within a certain range and achieve safe and reliable operation.

3.To control the deceleration and position of the piston rod to achieve safe and reliable work.

4.In addition to unstable internal pressure of the fluid, it ensures efficient flow of fluid.

5.Control the piston stroke pressure within a relatively small range to achieve more stable operation and more efficient control.

6.To control the flow and pressure of fluid to achieve energy saving.

In general, the main function of the hydraulic balance valve is to achieve precise control and stable operation of the hydraulic system, ensuring the safe and efficient operation of the hydraulic movable mechanism. In addition, the hydraulic balance valve can control the pressure of the piston stroke within a relatively small range, achieving more stable operation and more efficient control, and saving energy consumption of the hydraulic movable mechanism.

As an important hydraulic component, the quality of the hydraulic balance valve is very important. Therefore, when using the hydraulic balance valve, you must choose regular, reliable quality products to ensure the safe, stable and efficient operation of the hydraulic system.

Hydraulic balancing valve is an important component used to control flow and pressure in hydraulic systems. It adjusts the system pressure by adjusting the flow of liquid, thereby maintaining the stability and reliability of the system. Hydraulic balancing valve is mainly composed of valve body, valve core, spring, seal and other parts. Below we will introduce its working principle in detail.

1.Principle

The working principle of hydraulic balancing valves is based on a simple physical principle: the law of wave motion. According to the wave law, when liquid flows in a pipeline, a series of fluctuations will occur, which will cause high and low pressure areas inside the pipeline. Therefore, the impact of these high and low pressure areas on system stability must be considered when controlling liquid flow.

2.Structure

Hydraulic balancing valve usually consists of valve body, valve core, spring and seals. Among them, the valve body is a hollow metal cylindrical structure with some fixed holes on the inner wall; the valve core is a cylindrical structure with some switchable holes on its surface; the spring is used to support and adjust the valve core. location; seals are used to prevent liquid leakage.

3.Working process

When fluid flows from the system into the hydraulic balancing valve, it enters the interior of the valve core. Small holes in the valve core open or close based on system demand, thereby controlling the flow of liquid. During this process, the spring adjusts the position of the valve core to ensure that it can respond to system changes in a timely manner.

When liquid enters the interior of the valve body through the valve core, it passes through a series of holes and pipes. These holes and pipes are arranged according to certain rules to ensure that the liquid can form stable fluctuations during the flow process. These fluctuations create areas of high and low pressure that affect the stability of the entire system.

In order to solve this problem, the hydraulic balance valve adopts a special structural design: an adjustable air chamber is set between the valve core and the spring. When a high-pressure area occurs in the system, the air chamber is compressed, causing the spring to relax appropriately and adjust the valve core position to reduce flow. On the contrary, when a low-pressure area occurs in the system, the air cavity will expand, causing the spring to tighten appropriately and adjust the valve core position to increase flow. In this way, hydraulic balancing valves maintain system stability and reliability.

4.Application

Hydraulic balance valves are widely used in various hydraulic systems, such as engineering machinery, agricultural machinery, ships, aircraft and other fields. They are often used to control liquid flow and pressure to ensure proper operation and safety of the system.

In short, the hydraulic balance valve is an important hydraulic component. It adjusts the system pressure by adjusting the flow of liquid and maintains system stability and reliability. Its working principle is based on the wave law and adopts a special structural design to solve the impact of high and low pressure areas on system stability. It is widely used in various hydraulic systems.