Introduction to Counterbalance Valve

2024-01-29The function of the oil control counterbalance valve, also known as the load holding valve, is to use hydraulic pressure to keep the load stable and prevent the load from falling out of control when the oil pressure of the actuating element fails. This type of valve is usually located close to the actuator and can effectively control the movement of overload loads in cylinders and motors.

Selection and Application of counterbalance Valve

Selecting the appropriate counterbalance valve is critical to ensuring system performance. Our Bost Oil Control offers a variety of counterbalance valve and motion control valve modules to meet the performance needs of many different applications. You can choose from some of the most commonly used counterbalance valve modules based on your application needs.

For cylinder controls that want to reduce extension time without increasing pump flow capacity, a counterbalance valve with regeneration can be selected.

Types of counterbalance valves

The full range of Oil Control load holding includes: pilot operated check valves, counterbalance valves, counterbalance valves with regeneration, valves for motors including double cross relief valves, single/double counterbalancewith brake release and motion control , load reduction and pressure relief valves, inspection and metering valves, flow regulators and more.

To give a specific example, the regenerative load-holding counterbalance valves produced by Bost Oil Control include a variety of models, such as dual standard configurations, pressure-sensitive and solenoid-controlled types.

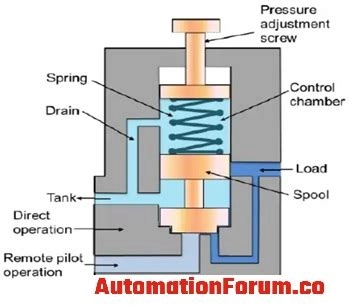

How the counterbalance valve works

A counterbalance valve is a combination of a pilot-operated relief valve and a reverse free-flow check valve. When used as a load-holding valve in a hydraulic system, a counterbalance valve prevents oil from flowing out of the cylinder that maintains the load. Without these valves, if the oil flow is out of control, the load cannot be controlled.

Conclusion

Overall, understanding and selecting a counterbalance valve that fits your application requirements are important steps in ensuring safe, efficient operation of your hydraulic system. I hope the above information will be helpful to you. If you need further information about a specific model or purchasing details, please consult the corresponding manufacturer or distributor.