Double Balancing Valve vs Single Balancing Valve

2024-03-07When it comes to hydronic systems, balancing valves play a crucial role in maintaining the optimal flow of water throughout the system. Two common types of balancing valves used in these systems are double balancing valves and single balancing valves. Both serve the purpose of controlling the flow of water, but they have distinct differences that make each suitable for specific applications.

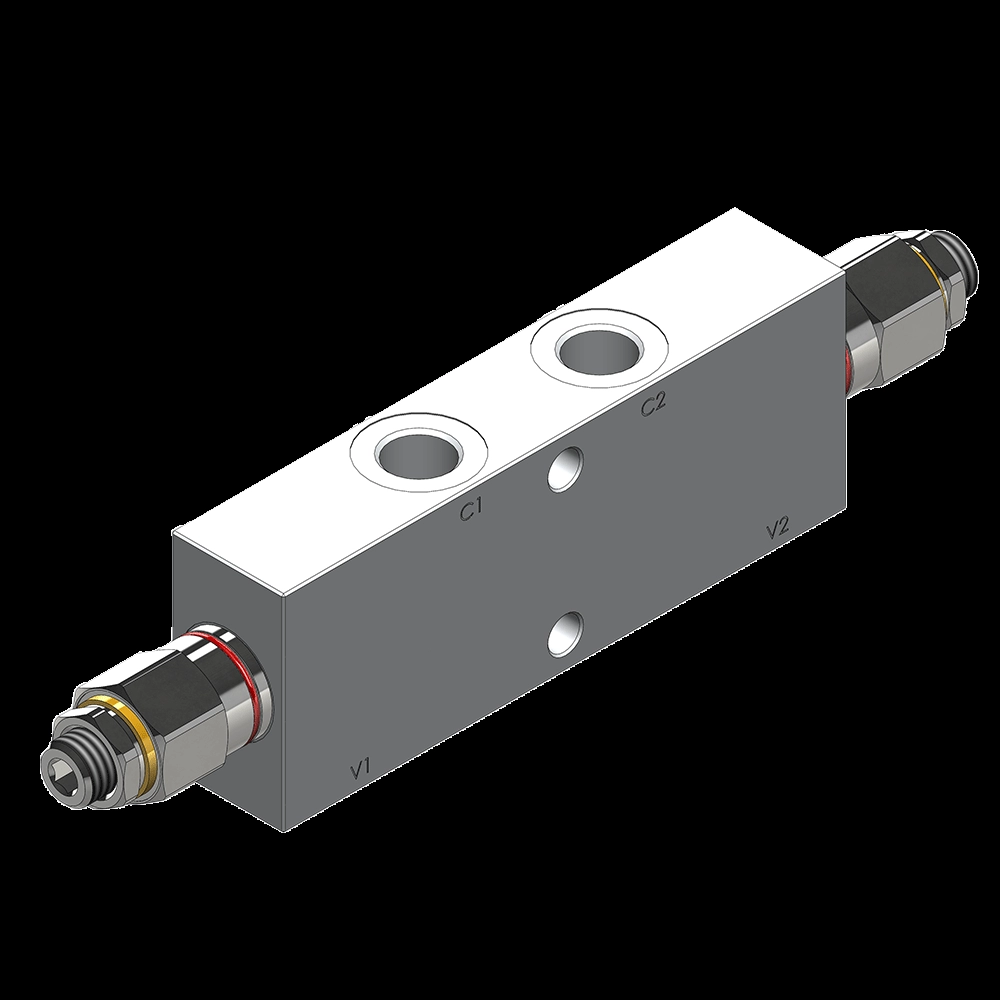

Double Balancing Valve

A double balancing valve, as the name suggests, consists of two separate valves in a single body. These valves are designed to provide precise control over both flow rate and pressure differential. The primary advantage of a double balancing valve is its ability to independently adjust the flow and pressure on both the supply and return sides of a hydronic system. This level of control is especially useful in systems with variable flow rates or complex piping configurations.

One of the key features of a double balancing valve is its ability to accurately measure and display the flow rate through the valve. This is typically achieved through the use of an integrated flow meter or gauge, allowing for real-time monitoring and adjustment of the flow. Additionally, double balancing valves often have a larger range of flow rates that they can accommodate, making them suitable for a wide range of hydronic system designs.

Single Balancing Valve

In contrast, a single balancing valve consists of a single valve that is designed to balance the flow and pressure in a hydronic system. While it may not offer the same level of independent control as a double balancing valve, a single balancing valve is still effective in ensuring proper flow distribution within the system. These valves are often used in simpler hydronic systems where the flow rates are relatively constant and the piping layout is less complex.

One of the key advantages of a single balancing valve is its simplicity. With only one valve to adjust, installation and maintenance are typically easier and more straightforward compared to double balancing valves. This can result in cost savings both in terms of initial installation and long-term maintenance.

Comparison

When comparing double balancing valves and single balancing valves, several factors should be taken into consideration to determine which type is best suited for a specific application.

Control and Precision

Double balancing valves offer a higher level of control and precision compared to single balancing valves. The ability to independently adjust flow and pressure on both the supply and return sides provides greater flexibility in managing complex hydronic systems with varying flow rates and pressure differentials.

System Complexity

For simpler hydronic systems with relatively constant flow rates and less complex piping layouts, a single balancing valve may be sufficient to ensure proper flow distribution. The simplicity of a single balancing valve can make it easier to install and maintain, which can be advantageous in these scenarios.

Cost

In general, double balancing valves tend to be more expensive than single balancing valves due to their additional features and capabilities. However, the higher cost may be justified in systems that require the level of control and precision that double balancing valves offer.

Application

The specific application and requirements of the hydronic system will ultimately determine whether a double balancing valve or a single balancing valve is more suitable. Factors such as flow rates, pressure differentials, system complexity, and budget constraints should all be taken into account when making this decision.

Conclusion

In conclusion, both double balancing valves and single balancing valves have their own unique advantages and are suitable for different applications. Double balancing valves provide a higher level of control and precision, making them ideal for complex hydronic systems with varying flow rates and pressure differentials. On the other hand, single balancing valves offer simplicity and cost-effectiveness, making them well-suited for simpler hydronic systems with relatively constant flow rates.

Ultimately, the choice between double balancing valves and single balancing valves should be based on a thorough understanding of the specific requirements of the hydronic system in question. By considering factors such as control needs, system complexity, and budget constraints, it is possible to determine which type of balancing valve is best suited for a particular application.