Ntọala ntọala na ụkpụrụ ọrụ nke sistemu hydraulic

2023-10-25一, Nchịkọta

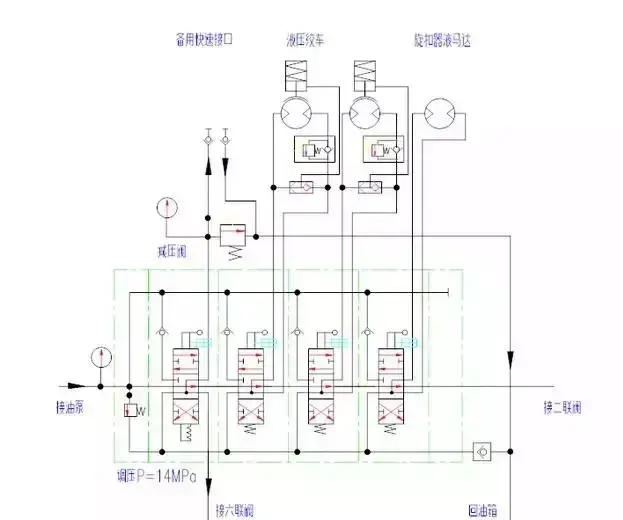

Usoro hydraulic na-agụnye isi mgbapụta mmanụ, tank hydraulic, nzacha, valvụ na-ebelata nrụgide, valve enyemaka, cylinder na-ebuli elu, cylinder telescopic, cylinder tong, cylinder outrigger, moto hydraulic, na ọrụ hydraulic dị iche iche. valves na ihe ndị ọzọ. Tupu akụrụngwa apụọ n'ụlọ ọrụ mmepụta ihe, a na-edozi nrụgide nke valve enyemaka, nrụgide na-ebelata valvụ na valvụ dị iche iche iji hụ na arụ ọrụ nchekwa nke usoro hydraulic, na ndị ọrụ anaghị ekwe ka ha gbanwee ngwa ngwa n'oge eji.

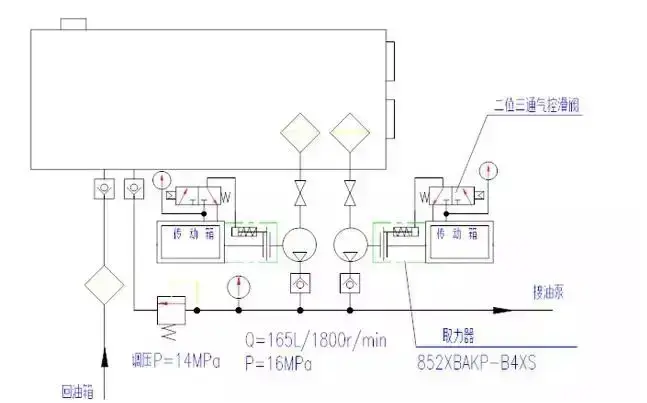

Usoro hydraulic na-agụnye isi usoro hydraulic na usoro nhazi hydraulic, na usoro abụọ ahụ na-ekekọrịta tank hydraulic.

1.Main hydraulic usoro

Usoro hydraulic bụ isi na-enye ike hydraulic na igwe na-egwupụta ihe n'oge nhazi akụrụngwa na arụ ọrụ nrụzi. Ejiri ya na valves dị iche iche iji chịkwaa ọrụ ziri ezi na nchekwa nke ngwá ọrụ hydraulic ọ bụla.

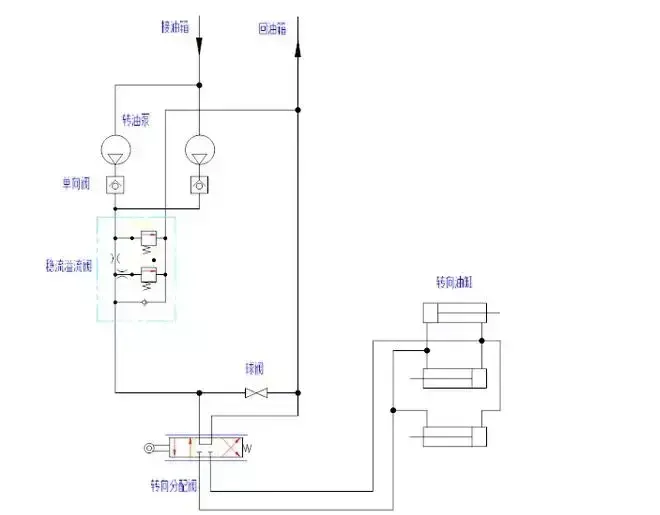

2.steering hydraulic usoro

Usoro hydraulic na-eduzi na-enye ike hydraulic maka njikwa ike hydraulic nke n'ihu axle nke ụgbọ ala. Ejiri ya na valvụ dị iche iche iji chịkwaa nrụgide, ntụgharị ụzọ na nkwụsi ike kachasị nke sistemu hydraulic, na-ahụ na njikwa ụgbọ ala dị ọkụ, mgbanwe, nchekwa na ntụkwasị obi.

3.Structural e ji mara

Usoro hydraulic nwere:

¨ Sistemụ hydraulic bụ isi

¨ Sistemụ hydraulic na-eduzi

4.Main hydraulic usoro

Mejupụtara ihe ndị a:

1) tank mmanụ hydraulic: na-echekwa, na-eme ka ọ dị jụụ, na-ebuli ma na-enyocha mmanụ hydraulic. A na-etinye tankị mmanụ ọkụ na:

l E nwere ihe mkpuchi oghere abụọ nke etinyere n'elu tank mmanụ. A na-etinye ihe nzacha ikuku hydraulic na mkpuchi manhole na mpaghara nloghachi mmanụ nke tankị mmanụ;

l Igwe ikuku hydraulic, na-enyocha ikuku nke na-esi na tank mmanụ, na-enyocha mmanụ mgbe a na-agbanye mmanụ ọkụ;

l ọkwa ọkwa mmiri, 2, etinyere n'akụkụ ihu nke tank mmanụ. Enwere nlele ọkwa mmiri abụọ, elu na obere. Ihe nlele ọkwa mmiri dị elu na-egosiputa ọkwa mmanụ mgbe agbadasịrị derrick; ihe nlele ọkwa mmiri dị ala na-egosiputa ọkwa mmanụ mgbe emechara derrick;

l A na-etinye ihe nlele ọkụ mmanụ n'akụkụ ihu nke tank mmanụ iji tụọ okpomọkụ mmanụ na tank. Okpomọkụ mmanụ na-arụ ọrụ dị n'etiti 30 na 70 Celsius. Enwere ọdụ ụgbọ mmiri abụọ na-alaghachi azụ mmanụ, nke edobere na efere ala nke tank mmanụ. A na-eji valvụ otu ụzọ rụọ ha ma jikọta ya n'otu n'otu. Isi ọkpọkọ nlọghachi mmanụ na valvụ enyemaka enyemaka ọdụ ụgbọ mmiri; valvụ otu ụzọ na-emechi na-akpaghị aka mgbe ị na-arụzi pipeline hydraulic iji gbochie ọnwụ nke mmanụ na tank;

l A na-edobe ọdụ ụgbọ mmiri n'elu efere ala nke tank mmanụ ma gbochie ya na plọg; meghee plọg ka igbapu mmanụ hydraulic tank;

l A na-edobe ọdụ ụgbọ mmiri nke isi mmanụ mmanụ n'akụkụ ihu nke tank mmanụ, na-etinyekwa ihe nzacha isi;

l A na-edobe ọdụ ụgbọ mmiri mgbapụta mmanụ ụgbọ mmiri n'akụkụ ihu nke tank mmanụ, ma tinye ihe nzacha mmanụ mmanụ;

l A na-edobe ọdụ ụgbọ mmiri nlọghachi mmanụ nke usoro ihe nrụnye na efere ala nke tank mmanụ ma kwadebere ya na valvụ otu ụzọ. valvụ otu ụzọ na-emechi na-akpaghị aka mgbe ị na-arụzi pipeline hydraulic iji gbochie ọnwụ nke mmanụ na tank;

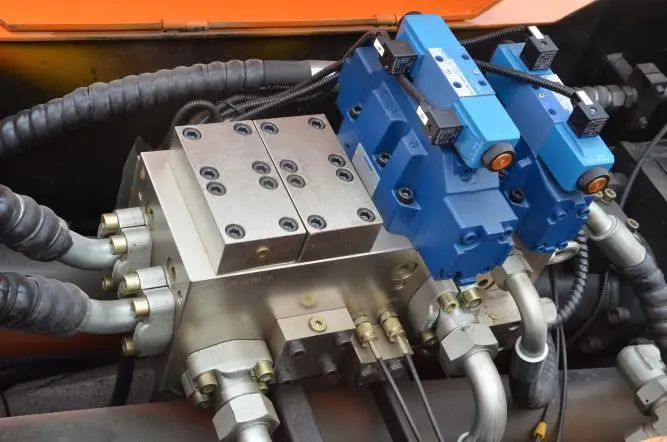

2) Mgbapụta mmanụ hydraulic: Otu ihe eji arụ ọrụ, nkeji 2, nke etinyere n'otu n'otu na igbe mbufe hydraulic abụọ, nke igwe mgbapụta mgbapụta torque na-ebugharị. Mgbe injin na-atụgharị, igbe na-ewepụ ike nwere ike ịkwọpụta mgbapụta mmanụ. A na-eji igbe na-ebupụ ike nwere njide hydraulic. Mgbe achọrọ ọrụ hydraulic, a na-arụ ọrụ "mkpọpu mmiri mmiri mmiri" nke igbe nchịkwa nke driller ma tọọ ya n'ọnọdụ "pump mmanụ m mechie". A na-ejikọta mgbapụta mmanụ m na-emepụta mmanụ nrụgide na-arụ ọrụ; aka ka atọrọ ka "oil pump II". "Nchie" ọnọdụ, a na-ejikọta mgbapụta mmanụ II ma na-emepụta mmanụ nrụgide na-arụ ọrụ ;. Aka ahụ nọ n'ọnọdụ na-anọpụ iche, ma nfuli mmanụ abụọ na-apụ ma kwụsị.

3) valvụ enyemaka: usoro na-arụ ọrụ pilot, 2 sets, nke etinyere na njedebe mmanụ nke isi mmanụ hydraulic mmanụ. Gbanwee nrụgide sistemu, gbochie oke sistemu, ma chekwaa sistemu na nchekwa akụrụngwa.

Ụkpụrụ nhazi nke valvụ enyemaka: Ọ na-agụnye valvụ pilot na valvụ slide isi. Akụkụ valvụ onye na-anya ụgbọ elu gụnyere ahụ valvụ, valvụ slide, nrụgide na-achịkwa mmiri na akụkụ ndị ọzọ. Enwere obere oghere a na valvụ slide valvụ isi, nke mere na mmanụ nrụgide ebubata nwere ike ịbanye n'ime ụlọ elu B nke valvụ slide ahụ. Mgbe nrụgide hydraulic na-arụ ọrụ na valvụ poppet dị obere karịa ike na-eme ka mmiri dị na mmiri, valvụ valvụ poppet nke pilot ga-eme ihe n'okpuru ọrụ nke ike mmiri. Ebe ọ bụ na ọ dịghị mmanụ na-asọba n'ime valvụ ahụ, nrụgide hydraulic na ụlọ mmanụ dị na elu na elu nke valvụ slide ahụ hà nhata. Ya mere, valvụ slide ahụ dị n'ọnọdụ dị oke egwu nke njedebe dị ala n'okpuru omume nke mmiri mmiri dị elu. A na-ebipụ ntinye na ntinye nke valvụ enyemaka site na valvụ slide, na valvụ enyemaka adịghị agafe; mgbe nrụgide hydraulic na-arụ ọrụ na valvụ poppet na-abawanye ka ike mmiri n'ihi mmụba nke ntinye ntinye nke valve enyemaka, a na-agbanye valvụ poppet Open, mmanụ dị n'elu ụlọ B nke valve slide na-abanye na mmanụ. mwepu nke valvụ site na mmanụ nloghachi ọdụ ụgbọ mmiri b na etiti site na oghere nke valvụ slide ahụ, wee na-ejupụta azụ na tank mmanụ. N'oge a, mmanụ nrụgide dị na ntinye mmanụ nke valve enyemaka na-esi na obere oghere a. A na-ejuputa ya n'elu ụlọ B. N'ihi na enwere mfu nrụgide mgbe mmanụ na-agafe na obere oghere a, nrụgide dị n'ime ụlọ B dị ala karịa nrụgide na ntinye mmanụ, na ọdịiche nrụgide na-apụta n'etiti elu na nke dị ala. nke valvụ slide. Ya mere, n'okpuru omume nke nrụgide dị iche n'etiti elu na nke ala nsọtụ, valvụ slide na-emeri ike mmiri, na valvụ valvụ nke onwe ya na esemokwu na-aga n'ihu, na-emeghe ntinye na nloghachi nke valvụ enyemaka, mmanụ na-asọba. laghachi na tank. Mgbe emeghechara valvụ slide ahụ, ike hydraulic na-ebugharị mmiri ahụ. Na-emetụta, nrụgide ntinye P ga-anọgide na-ebili, na valvụ slide ga-aga n'ihu na-aga n'ihu. Mgbe ike nke valvụ slide ahụ na-edozi n'otu ebe, ntinye ntinye nke valvụ enyemaka ga-eme ka ọ kwụsie ike na uru ụfọdụ, nke a na-akpọ nrụgide ntọala nke valve enyemaka.

4) Ihe nzacha mmanu mmanu: ihe nkpuchi nke onwe n'èzí tank, etinyere n'akụkụ nke tank mmanụ hydraulic, a na-emikpu tube mmanụ n'okpuru ọkwa mmiri dị na tank mmanụ, na-ekpughe isi nzacha nke nzacha n'èzí. tank mmanụ; a na-eji valvụ na-ekpuchi onwe ya, valvụ na-agafe agafe, ihe nzacha na-emetọ onye na-ebugharị na ngwaọrụ ndị ọzọ. Mgbe ị na-edochi ma ọ bụ na-ehicha ihe nzacha, enwere ike ịkwasa ya ma tinye ya n'èzí tank. Mgbe ewepụchara ihe nzacha ahụ, valvụ nke na-ejide onwe ya na-emechi na-akpaghị aka iji gbochie mmanụ si na tank ahụ pụta. valvụ gafere, mgbe ihe nzacha kpuchiri, ekwesighi imechi igwe ozugbo maka mmezi. Enwere ike ịgbasa mmanụ ahụ site na valvụ gafere, enwere ike mechie igwe ahụ ka ọ dị ọcha ma ọ bụ dochie ihe nzacha n'oge kwesịrị ekwesị. Ngosipụta dị iche nrụgide bụ usoro nleba anya n'ibu. Ọ bụrụ na ihe nzacha ahụ kpuchiri, ọ ga-emetụta ọdịiche nrụgide mmanụ na pointer ga-efegharị. , Mgbe ọ na-atụ aka na mpaghara uhie, a ga-emechi igwe maka nhicha ma ọ bụ dochie ihe nzacha. A na-etinye valvụ bọọlụ na ntinye nke nzacha iji mechie ya n'oge mmezi na ịrụzi pipeline hydraulic iji gbochie mmanụ na-efunahụ na tank.

5) Nlaghachi mmanụ mmanụ: Ejiri valvụ gafere yana ihe ngosi dị iche nrụgide. Ihe nzacha na-ehichapụ ihe ndị siri ike na mmanụ hydraulic, na-egbochi ihe ndị na-adịghị ọcha na pipeline ịbanye na tank, ma na-eme ka mmanụ usoro dị ọcha; A na-eji valvụ gafere mgbe ihe nzacha kpuchiri ya. Mgbe nke ahụ gasịrị, a naghị ekwe ka ọ mechie igwe ozugbo maka mmezi. Enwere ike ịgbasa mmanụ ahụ site na valvụ na-agafe agafe, a ga-emechikwa igwe ahụ ka ọ dị ọcha ma ọ bụ dochie ihe nzacha n'oge kwesịrị ekwesị. Ihe ngosi dị iche na nrụgide bụ usoro nyocha ihe nlegharị anya n'ibu. Ọ bụrụ na ihe nzacha ahụ kpuchiri, nke na-emetụta ọdịiche nrụgide mmanụ, ihe ngosi ahụ na-agbatị ma na-atụ aka na mpaghara uhie. Mgbe ọ dị mkpa, a ga-emechi igwe ahụ ka ọ dị ọcha ma ọ bụ dochie ihe nzacha.

7) Na-ebuli mmanụ mmanụ: ihe owuwu atọ mejupụtara mmanụ ala, nke nwere valvụ otu ụzọ; na-ebuli na ọdịda derrick, otu ụzọ trotul valve iji gbochie ike ndọda n'oge usoro ọdịda derrick, ma chebe nchekwa nke ibuli elu na ọdịda. Igwe a na-eji cylinders ebuli okpukpu abụọ.

l Usoro na ụkpụrụ ọrụ: Ọdịdị ahụ nwere cylinder, piston ọkwa mbụ, piston ọkwa nke abụọ, piston nke atọ, mgbanaka nduzi, mgbanaka akara na akụkụ ndị ọzọ. The cylinder isi na-onwem na pin ntị efere, nke ejikọrọ na ofu ntị efere na etiti cross doo site a ntụtụ. Ejikọ mkpara piston nke atọ na ntụtụ ọnụ ụzọ ahụ dị ala n'otu ụzọ ahụ. Nke mbụ na nke abụọ-larịị plunger nwere usoro ihe omume otu ụzọ. N'okpuru ọrụ mmanụ hydraulic, plunger na-agbatị ike wee weghachi site na ịdị arọ nke ya mgbe ọ na-alọghachi. Piston dị larịị nke atọ nwere usoro omume ụzọ abụọ. N'okpuru ọrụ mmanụ hydraulic, piston piston ọkwa nke atọ kwadoro ndọtị na nkwụghachi azụ. Ejiri cylinder na-ebuli elu nwere ọdụ ụgbọ mmiri atọ, P1, P2 na P3. Ọdụ ụgbọ mmiri P1 dị na isi cylinder, na-ejikọ ọnụ ụlọ na-arụ ọrụ plunger na ọnụ ụlọ piston nke atọ. Enwere valvụ trotul nke nwere otu ụzọ na ngafe mmanụ; ọdụ ụgbọ mmiri mmanụ P2 dị na mkpanaka piston nke atọ, na-ejikọ ọnụ ụlọ piston rodless nke atọ. Enwere oghere mkpọda n'ime oghere mkpanaka na ụzọ mmanụ; ọdụ ụgbọ mmiri P3 dị na mkpanaka piston nke atọ, na-ejikọ ọnụ ụlọ na-arụ ọrụ plunger na ọnụ ụlọ piston rodless nke atọ, ma jikọta ya na ụzọ mmanụ P1. Enwere oghere n'ọnụ ụzọ mmanụ. A na-enye oghere ikuku n'isi piston cylinder nke atọ nke isi mmanụ mmanụ, a na-etinyekwa nkwụnye ikuku na ya.

l Ikuku ikuku: Tupu ọ bụla ebuli na ọdịda nke derrick, ikuku na-ebuli cylinder na telescopic cylinder kwesịrị ịhapụ kpamkpam. Mmanụ hydraulic nwere ikuku, na ntapu na pipeline na-ebute ikuku na cylinder. Mgbe a na-adọba ụgbọala na-ebuli elu na cylinder telescopic ruo ogologo oge, ikuku ga-agbakọta na akụkụ elu nke cylinder ahụ. Mgbe a na-ebuli elu ma na-agbadata, ohere nke ihe mberede ga-abawanye, ikuku ga-agbapụ, a ga-ewepụkwa ihe ize ndụ zoro ezo nke ihe mberede.

l Sistemụ pipeline ikuku mwepu: Mepee valvụ agịga E na isii njikọ valvụ akara panel na-etolite a ezigbo sekit maka ebuli cylinders P1 na P3, na jikọọ mmanụ azụ pipeline. Ebuli valvụ njikwa na-ebuli elu, mmanụ hydraulic nke mgbapụta mmanụ na-abanye cylinder na-ebuli elu site na P1, wee laghachi na tank mmanụ site na P3. Usoro hydraulic na-arụ ọrụ na-enweghị ibu; usoro hydraulic na-agba ọsọ na-enweghị ibu maka 5 ruo 10 nkeji, wepụ ihe nkwụsị na pipeline na gas cylinder na-ebuli elu.

l Na-ewepụ ikuku site na oghere mkpanaka nke piston nke atọ nke igwe na-ebuli elu: mechie valve E, na-ebuli cylinders P1 na P3 na-emepụta sekit mechiri emechi. Jiri nwayọọ bulie aka nke valvụ njikwa cylinder na-ebuli elu, nye mmanụ nrụgide n'ime ụlọ dị ala nke cylinder na-ebuli elu, na-achịkwa nrụgide mmanụ na 2 ~ 3MPa, mepee plọg ọbara na piston cylinder isi nke atọ nke cylinder, wee wepụ ya. ikuku na-ebuli cylinder.

l Nyocha nyocha nke sistemu: Jiri nwayọ bulie valvụ njikwa cylinder na-ebuli elu, nye mmanụ nrụgide n'ọnụ ụlọ dị ala nke cylinder na-ebuli elu, jiri nwayọ bulie derrick, hapụ 100 ~ 200mm pụọ na nkwado ihu nke derrick, kwụsị ibuli elu, ma debe derrick. na steeti maka nkeji 5. Lelee usoro hydraulic na pipeline, ọ gaghị enwe nkwụsị ebe ọ bụla; lelee derick, ekwesighi inwe ebe doro anya.

l Usoro nchekwa: The derrick dị arọ, na enwere ohere dị ukwuu nke ihe mberede mgbe ebuli na ibelata derrick. Lezienụ anya n'oge arụ ọrụ ma soro usoro ọrụ siri ike. Edobere ọtụtụ usoro nchekwa maka cylinder ebuli nchekwa dị mma. Ọbụlagodi na valvụ njikwa cylinder na-ebuli ada ada ma ọ bụ agbajie ma mebie eriri hydraulic, cylinder na-ebuli elu ga-ebelata ọsọ ọsọ nke Derrick ma gbochie nnukwu ihe ọghọm.

l derrick na-ebuli: Mmanụ hydraulic na-abanye n'ime ụlọ ọrụ nke cylinder mmanụ site na ọdụ ụgbọ mmiri P1 site na valvụ otu ụzọ. Plunger ọkwa mbụ na-ebu ụzọ agbatị. Mgbe ha rutere n'ọnọdụ ahụ, plunger ọkwa nke abụọ na mkpanaka piston nke atọ na-agbatị n'usoro. Piston dị larịị nke atọ nwere mkpanaka. Mmanụ dị n'ime oghere na-alaghachi site na P2. Ebe ọ bụ na ọdụ ụgbọ mmiri P2 nwere oghere na-agbagharị agbagharị, mgbe piston nke atọ na-agbatị, oghere nke valvụ nchịkwa kwesịrị ibelata ma gbasaa ngwa ngwa mgbatị ahụ. Ma ọ bụghị ya, nrụgide nke usoro hydraulic ga-abawanye;

l Belata derrick: Mmanụ hydraulic na-abanye n'ime oghere mkpanaka nke piston nke atọ site na P2, na-akpali piston ka ọ laghachi azụ. Mmanụ dị na oghere na-enweghị mkpanaka na-alaghachi na mmanụ site na trottle P1, na cylinder na-eweghachi nwayọọ nwayọọ iji gbochie ike ndọda; Usoro ndọghachi azụ nke plunger na piston ọ bụla bụ: nke mbụ, piston nke agba nke atọ na-eweghachite. Mgbe ha rutere n'ọnọdụ ahụ, ọkwa nke abụọ na nke mbụ na-agbaghachi azụ n'usoro. Mgbe plungers nke abụọ na nke mbụ laghachiri, ha na-ada azụ site na ịdị arọ nke aka ha na-ebunyeghị mmanụ hydraulic na cylinder. N'oge a, enwere ike ibelata ọsọ engine na njikwa ọrụ na-eji nwayọọ nwayọọ laghachi na derrick.

8) Telescopic cylinder, hydraulic telescopic derrick okpukpu abụọ.

l Ọdịdị mejupụtara: Extra ogologo plunger cylinder, na ngụkọta cylinder ogologo nke 14 ka 16m. Enwere ọdụ ụgbọ mmiri na njedebe nke plunger, a na-etinyekwa valvụ trotul nke otu ụzọ na ụzọ mmanụ; isi cylinder nwere plọg na-agba ọbara. A na-ejikọta ahụ silinda mmanụ ahụ n'elu ahụ nke derrick na bolts U, na elu na-agbanye n'ime mgbanaka oche nke derrick beam. A na-eji efere njikọ dị n'akụkụ ala nke plunger, nke a na-agbanye n'osisi nke ala nke derrick.

l usoro ọrụ. A na-agbatị derrick nke dị n'ala nke abụọ, a na-ejikwa valvụ nchịkwa nke cylinder mmanụ telescopic na-ebuli elu. Mmanụ nrụgide na-abanye na cylinder site na ọdụ ụgbọ mmiri na njedebe nke mkpanaka plunger, valvụ otu ụzọ, na oghere oghere, na-eme ka cylinder gbatịa, na-eme ka ahụ dị elu nke derrick bilie n'akụkụ egwu ahụ. Derrick dị ebe a na-ekpochikwa usoro ntụtụ na-akpaghị aka. A na-eweghachite derrick nke dị n'ala nke abụọ, ma ejiri aka wepụta pin nchekwa. Nke mbụ, a na-arụ ọrụ valvụ na-achịkwa telescopic cylinder iji bulie elu, nke mere na derrick nke okpukpu abụọ ji nwayọọ nwayọọ na-ebili ihe dịka 200mm. Usoro nchichi mkpọchi na-emeghe na-akpaghị aka, mgbe ahụ, a na-arụ ọrụ valvụ njikwa telescopic cylinder iji kwatuo ala, na mmanụ hydraulic dị na cylinder bụ nrụgide nke ịdị arọ nke onwe nke akụkọ ihe mere eme nke abụọ derrick na-esi na cylinder na-esi na throttle. ọdụ ụgbọ mmiri na ọdụ mmanụ na njedebe nke plunger. Derrick nke okpukpu abụọ dara. A na-edozi ọsọ na-ada ada site na oghere mmeghe nke otu ụzọ valvụ trotul na valvụ njikwa telescopic cylinder.

l Usoro nchekwa: Derrick dị n'ala nke abụọ dị arọ karị, na enwere ohere dị ukwuu nke ihe mberede mgbe ị na-ebuli ma na-eweda derrick. Lezienụ anya n'oge arụ ọrụ ma soro usoro ọrụ siri ike. The nchekwa telescopic cylinder na-onwem na otu ụzọ trotul valvụ. Ọbụlagodi na valvụ njikwa cylinder daa ma ọ bụ gbajie hydraulic hose ma mebie, cylinder ahụ ga-ebelata ọsọ nke derrick nke ọma wee gbochie nnukwu ihe ọghọm.

l Ikuku ikuku: Mgbe etinyere cylinder ahụ ruo oge ụfọdụ, ikuku ga-esi na akara ahụ pụta. Silinda arụnyere ọhụrụ nwere ikuku karịa n'ime. Ya mere, tupu ọrụ ọ bụla nke telescopic cylinder, a ghaghị ịhapụ ikuku dị na cylinder telescopic iji gbochie usoro mgbasawanye nke cylinder ahụ. Na-akpụ akpụ. Were obere aka nke valvụ njikwa cylinder na-ebuli elu, nye mmanụ nrụgide na cylinder telescopic, ma jikwaa nrụgide mmanụ na 2 ruo 3 MPa. Mepee plọg ikuku dị n'elu cylinder ka ịwepụ ikuku na cylinder telescopic. Mgbe igbapu, ikesie aku. Emegharịla ka ị na-agbagharị. Mepee eriri nchekwa derrick.

9) Mgbochi cylinder: Silinda nwere usoro piston ụzọ abụọ, a na-enyekwa ngwaọrụ nchekwa na nsọtụ abụọ nke isi cylinder na mkpuchi cylinder iji gbochie mmetụta hydraulic nke cylinder ahụ. Mgbe mkpisi piston nke mmanụ silinda mmanụ laghachiri, a na-eme ka eriri isi pusi nke ihe ebuli elu na-eme ka ọ sie ike na ịtọghe eriri a na-egwupụta ihe; mkpanaka piston na-agbatị ma eriri isi nwamba laghachiri.

10) Hydraulic obere winch: usoro mbelata mbara ala, nke nwere breeki na valvụ nguzozi, ọ dị mma ibuli ihe ma nwee ike ifegharị na ikuku.

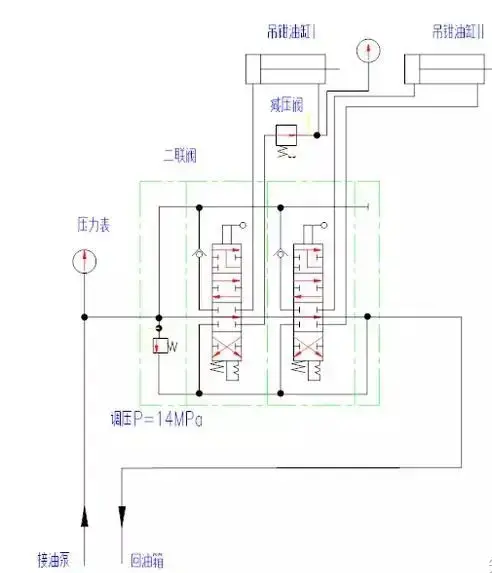

11) valvụ okpukpu abụọ: Awụnyere na akụkụ ala nke igbe nchịkwa nke driller, ọ na-agụnye efere valvụ ntinye mmanụ, mmanụ valvụ nloghachi mmanụ na mbadamba valve abụọ na-arụ ọrụ. Mpempe valvụ ntinye mmanụ na-eji valvụ nchekwa iji dozie nrụgide na-arụ ọrụ na-abanye na valvụ abụọ. Mepee ma mee ka nut ahụ sie ike, ma tụgharịa ihe nkedo na-agbanwe agbanwe ka ọ gbanwee nrụgide ngbanwe nke valvụ nchekwa. Mgbe ị na-abata, nrụgide na-agbanwe agbanwe na-abawanye, na mgbe ị na-apụ apụ, nrụgide na-agbanwe na-ebelata. Rịba ama na ka emezigharị, mee ka okpu azụ sie ike ma kpọchie mkpụrụ na-agbanwe agbanwe. A na-ejikwa aka na-achịkwa efere valve na-arụ ọrụ.

A. Na-ebuli tong cylinder valvụ I: Na-achịkwa ihe na-ebuli tong I cylinder ka ịgbatị ma weghachite iji tọpụ ma mee ka eriri isi arịlịka sie ike. A na-edozi isi valve na ọnọdụ valvụ na-ese n'elu mmiri iji mepụta sekit cylinder dị iche. Mmanụ mmanụ na-agbapụta mmanụ na mmanụ oghere na-abanye n'ime oghere na-enweghị mkpanaka nke cylinder mmanụ n'otu oge, na-eme ka mkpanaka piston gbatịa ngwa ngwa; valvụ isi mmiri na-alaghachi, hapụ aka ahụ, na valvụ isi na-alaghachi na-akpaghị aka N'ọnọdụ na-anọpụ iche, mmegharị cylinder na-akwụsị.

B. Na-ebuli tong cylinder valvụ II: Na-achịkwa ihe na-ebuli tong II cylinder ka ịgbatị na retract ka ịtọpụ na ikesie ike arịlịka isi eriri. A na-edozi isi valve na ọnọdụ valvụ na-ese n'elu mmiri iji mepụta sekit cylinder dị iche. Mmanụ mmanụ na-agbapụta mmanụ na mmanụ oghere na-abanye n'ime oghere na-enweghị mkpanaka nke cylinder mmanụ n'otu oge, na-eme ka mkpanaka piston gbatịa ngwa ngwa; valvụ isi mmiri na-alaghachi, hapụ aka ahụ, na valvụ isi na-alaghachi na-akpaghị aka N'ọnọdụ na-anọpụ iche, mmegharị cylinder na-akwụsị.

7) Na-ebuli mmanụ mmanụ: ihe owuwu atọ mejupụtara mmanụ ala, nke nwere valvụ otu ụzọ; na-ebuli na ọdịda derrick, otu ụzọ trotul valve iji gbochie ike ndọda n'oge usoro ọdịda derrick, ma chebe nchekwa nke ibuli elu na ọdịda. Igwe a na-eji cylinders ebuli okpukpu abụọ.

l Usoro na ụkpụrụ ọrụ: Ọdịdị ahụ nwere cylinder, piston ọkwa mbụ, piston ọkwa nke abụọ, piston nke atọ, mgbanaka nduzi, mgbanaka akara na akụkụ ndị ọzọ. The cylinder isi na-onwem na pin ntị efere, nke ejikọrọ na ofu ntị efere na etiti cross doo site a ntụtụ. Ejikọ mkpara piston nke atọ na ntụtụ ọnụ ụzọ ahụ dị ala n'otu ụzọ ahụ. Nke mbụ na nke abụọ-larịị plunger nwere usoro ihe omume otu ụzọ. N'okpuru ọrụ mmanụ hydraulic, plunger na-agbatị ike wee weghachi site na ịdị arọ nke ya mgbe ọ na-alọghachi. Piston dị larịị nke atọ nwere usoro omume ụzọ abụọ. N'okpuru ọrụ mmanụ hydraulic, piston piston ọkwa nke atọ kwadoro ndọtị na nkwụghachi azụ. Ejiri cylinder na-ebuli elu nwere ọdụ ụgbọ mmiri atọ, P1, P2 na P3. Ọdụ ụgbọ mmiri P1 dị na isi cylinder, na-ejikọ ọnụ ụlọ na-arụ ọrụ plunger na ọnụ ụlọ piston nke atọ. Enwere valvụ trotul nke nwere otu ụzọ na ngafe mmanụ; ọdụ ụgbọ mmiri mmanụ P2 dị na mkpanaka piston nke atọ, na-ejikọ ọnụ ụlọ piston rodless nke atọ. Enwere oghere mkpọda n'ime oghere mkpanaka na ụzọ mmanụ; ọdụ ụgbọ mmiri P3 dị na mkpanaka piston nke atọ, na-ejikọ ọnụ ụlọ na-arụ ọrụ plunger na ọnụ ụlọ piston rodless nke atọ, ma jikọta ya na ụzọ mmanụ P1. Enwere oghere n'ọnụ ụzọ mmanụ. A na-enye oghere ikuku n'isi piston cylinder nke atọ nke isi mmanụ mmanụ, a na-etinyekwa nkwụnye ikuku na ya.

l Ikuku ikuku: Tupu ọ bụla ebuli na ọdịda nke derrick, ikuku na-ebuli cylinder na telescopic cylinder kwesịrị ịhapụ kpamkpam. Mmanụ hydraulic nwere ikuku, na ntapu na pipeline na-ebute ikuku na cylinder. Mgbe a na-adọba ụgbọala na-ebuli elu na cylinder telescopic ruo ogologo oge, ikuku ga-agbakọta na akụkụ elu nke cylinder ahụ. Mgbe a na-ebuli elu ma na-agbadata, ohere nke ihe mberede ga-abawanye, ikuku ga-agbapụ, a ga-ewepụkwa ihe ize ndụ zoro ezo nke ihe mberede.

l Sistemụ pipeline ikuku mwepu: Mepee valvụ agịga E na isii njikọ valvụ akara panel na-etolite a ezigbo sekit maka ebuli cylinders P1 na P3, na jikọọ mmanụ azụ pipeline. Ebuli valvụ njikwa na-ebuli elu, mmanụ hydraulic nke mgbapụta mmanụ na-abanye cylinder na-ebuli elu site na P1, wee laghachi na tank mmanụ site na P3. Usoro hydraulic na-arụ ọrụ na-enweghị ibu; usoro hydraulic na-agba ọsọ na-enweghị ibu maka 5 ruo 10 nkeji, wepụ ihe nkwụsị na pipeline na gas cylinder na-ebuli elu.

l Na-ewepụ ikuku site na oghere mkpanaka nke piston nke atọ nke igwe na-ebuli elu: mechie valve E, na-ebuli cylinders P1 na P3 na-emepụta sekit mechiri emechi. Jiri nwayọọ bulie aka nke valvụ njikwa cylinder na-ebuli elu, nye mmanụ nrụgide n'ime ụlọ dị ala nke cylinder na-ebuli elu, na-achịkwa nrụgide mmanụ na 2 ~ 3MPa, mepee plọg ọbara na piston cylinder isi nke atọ nke cylinder, wee wepụ ya. ikuku na-ebuli cylinder.

l Nyocha nyocha nke sistemu: Jiri nwayọ bulie valvụ njikwa cylinder na-ebuli elu, nye mmanụ nrụgide n'ọnụ ụlọ dị ala nke cylinder na-ebuli elu, jiri nwayọ bulie derrick, hapụ 100 ~ 200mm pụọ na nkwado ihu nke derrick, kwụsị ibuli elu, ma debe derrick. na steeti maka nkeji 5. Lelee usoro hydraulic na pipeline, ọ gaghị enwe nkwụsị ebe ọ bụla; lelee derick, ekwesighi inwe ebe doro anya.

l Usoro nchekwa: The derrick dị arọ, na enwere ohere dị ukwuu nke ihe mberede mgbe ebuli na ibelata derrick. Lezienụ anya n'oge arụ ọrụ ma soro usoro ọrụ siri ike. Edobere ọtụtụ usoro nchekwa maka cylinder ebuli nchekwa dị mma. Ọbụlagodi na valvụ njikwa cylinder na-ebuli ada ada ma ọ bụ agbajie ma mebie eriri hydraulic, cylinder na-ebuli elu ga-ebelata ọsọ ọsọ nke Derrick ma gbochie nnukwu ihe ọghọm.

l derrick na-ebuli: Mmanụ hydraulic na-abanye n'ime ụlọ ọrụ nke cylinder mmanụ site na ọdụ ụgbọ mmiri P1 site na valvụ otu ụzọ. Plunger ọkwa mbụ na-ebu ụzọ agbatị. Mgbe ha rutere n'ọnọdụ ahụ, plunger ọkwa nke abụọ na mkpanaka piston nke atọ na-agbatị n'usoro. Piston dị larịị nke atọ nwere mkpanaka. Mmanụ dị n'ime oghere na-alaghachi site na P2. Ebe ọ bụ na ọdụ ụgbọ mmiri P2 nwere oghere na-agbagharị agbagharị, mgbe piston nke atọ na-agbatị, oghere nke valvụ nchịkwa kwesịrị ibelata ma gbasaa ngwa ngwa mgbatị ahụ. Ma ọ bụghị ya, nrụgide nke usoro hydraulic ga-abawanye;

l Belata derrick: Mmanụ hydraulic na-abanye n'ime oghere mkpanaka nke piston nke atọ site na P2, na-akpali piston ka ọ laghachi azụ. Mmanụ dị na oghere na-enweghị mkpanaka na-alaghachi na mmanụ site na trottle P1, na cylinder na-eweghachi nwayọọ nwayọọ iji gbochie ike ndọda; Usoro ndọghachi azụ nke plunger na piston ọ bụla bụ: nke mbụ, piston nke agba nke atọ na-eweghachite. Mgbe ha rutere n'ọnọdụ ahụ, ọkwa nke abụọ na nke mbụ na-agbaghachi azụ n'usoro. Mgbe plungers nke abụọ na nke mbụ laghachiri, ha na-ada azụ site na ịdị arọ nke aka ha na-ebunyeghị mmanụ hydraulic na cylinder. N'oge a, enwere ike ibelata ọsọ engine na njikwa ọrụ na-eji nwayọọ nwayọọ laghachi na derrick.

8) Telescopic cylinder, hydraulic telescopic derrick okpukpu abụọ.

l Ọdịdị mejupụtara: Extra ogologo plunger cylinder, na ngụkọta cylinder ogologo nke 14 ka 16m. Enwere ọdụ ụgbọ mmiri na njedebe nke plunger, a na-etinyekwa valvụ trotul nke otu ụzọ na ụzọ mmanụ; isi cylinder nwere plọg na-agba ọbara. A na-ejikọta ahụ silinda mmanụ ahụ n'elu ahụ nke derrick na bolts U, na elu na-agbanye n'ime mgbanaka oche nke derrick beam. A na-eji efere njikọ dị n'akụkụ ala nke plunger, nke a na-agbanye n'osisi nke ala nke derrick.

l usoro ọrụ. A na-agbatị derrick nke dị n'ala nke abụọ, a na-ejikwa valvụ nchịkwa nke cylinder mmanụ telescopic na-ebuli elu. Mmanụ nrụgide na-abanye na cylinder site na ọdụ ụgbọ mmiri na njedebe nke mkpanaka plunger, valvụ otu ụzọ, na oghere oghere, na-eme ka cylinder gbatịa, na-eme ka ahụ dị elu nke derrick bilie n'akụkụ egwu ahụ. Derrick dị ebe a na-ekpochikwa usoro ntụtụ na-akpaghị aka. A na-eweghachite derrick nke dị n'ala nke abụọ, ma ejiri aka wepụta pin nchekwa. Nke mbụ, a na-arụ ọrụ valvụ na-achịkwa telescopic cylinder iji bulie elu, nke mere na derrick nke okpukpu abụọ ji nwayọọ nwayọọ na-ebili ihe dịka 200mm. Usoro nchichi mkpọchi na-emeghe na-akpaghị aka, mgbe ahụ, a na-arụ ọrụ valvụ njikwa telescopic cylinder iji kwatuo ala, na mmanụ hydraulic dị na cylinder bụ nrụgide nke ịdị arọ nke onwe nke akụkọ ihe mere eme nke abụọ derrick na-esi na cylinder na-esi na throttle. ọdụ ụgbọ mmiri na ọdụ mmanụ na njedebe nke plunger. Derrick nke okpukpu abụọ dara. A na-edozi ọsọ na-ada ada site na oghere mmeghe nke otu ụzọ valvụ trotul na valvụ njikwa telescopic cylinder.

l Usoro nchekwa: Derrick dị n'ala nke abụọ dị arọ karị, na enwere ohere dị ukwuu nke ihe mberede mgbe ị na-ebuli ma na-eweda derrick. Lezienụ anya n'oge arụ ọrụ ma soro usoro ọrụ siri ike. The nchekwa telescopic cylinder na-onwem na otu ụzọ trotul valvụ. Ọbụlagodi na valvụ njikwa cylinder daa ma ọ bụ gbajie hydraulic hose ma mebie, cylinder ahụ ga-ebelata ọsọ nke derrick nke ọma wee gbochie nnukwu ihe ọghọm.

l Ikuku ikuku: Mgbe etinyere cylinder ahụ ruo oge ụfọdụ, ikuku ga-esi na akara ahụ pụta. Silinda arụnyere ọhụrụ nwere ikuku karịa n'ime. Ya mere, tupu ọrụ ọ bụla nke telescopic cylinder, a ghaghị ịhapụ ikuku dị na cylinder telescopic iji gbochie usoro mgbasawanye nke cylinder ahụ. Na-akpụ akpụ. Were obere aka nke valvụ njikwa cylinder na-ebuli elu, nye mmanụ nrụgide na cylinder telescopic, ma jikwaa nrụgide mmanụ na 2 ruo 3 MPa. Mepee plọg ikuku dị n'elu cylinder ka ịwepụ ikuku na cylinder telescopic. Mgbe igbapu, ikesie aku. Emegharịla ka ị na-agbagharị. Mepee eriri nchekwa derrick.

9) Mgbochi cylinder: Silinda nwere usoro piston ụzọ abụọ, a na-enyekwa ngwaọrụ nchekwa na nsọtụ abụọ nke isi cylinder na mkpuchi cylinder iji gbochie mmetụta hydraulic nke cylinder ahụ. Mgbe mkpisi piston nke mmanụ silinda mmanụ laghachiri, a na-eme ka eriri isi pusi nke ihe ebuli elu na-eme ka ọ sie ike na ịtọghe eriri a na-egwupụta ihe; mkpanaka piston na-agbatị ma eriri isi nwamba laghachiri.

10) Hydraulic obere winch: usoro mbelata mbara ala, nke nwere breeki na valvụ nguzozi, ọ dị mma ibuli ihe ma nwee ike ifegharị na ikuku.

11) valvụ okpukpu abụọ: Awụnyere na akụkụ ala nke igbe nchịkwa nke driller, ọ na-agụnye efere valvụ ntinye mmanụ, mmanụ valvụ nloghachi mmanụ na mbadamba valve abụọ na-arụ ọrụ. Mpempe valvụ ntinye mmanụ na-eji valvụ nchekwa iji dozie nrụgide na-arụ ọrụ na-abanye na valvụ abụọ. Mepee ma mee ka nut ahụ sie ike, ma tụgharịa ihe nkedo na-agbanwe agbanwe ka ọ gbanwee nrụgide ngbanwe nke valvụ nchekwa. Mgbe ị na-abata, nrụgide na-agbanwe agbanwe na-abawanye, na mgbe ị na-apụ apụ, nrụgide na-agbanwe na-ebelata. Rịba ama na ka emezigharị, mee ka okpu azụ sie ike ma kpọchie mkpụrụ na-agbanwe agbanwe. A na-ejikwa aka na-achịkwa efere valve na-arụ ọrụ.

A. Na-ebuli tong cylinder valvụ I: Na-achịkwa ihe na-ebuli tong I cylinder ka ịgbatị ma weghachite iji tọpụ ma mee ka eriri isi arịlịka sie ike. A na-edozi isi valve na ọnọdụ valvụ na-ese n'elu mmiri iji mepụta sekit cylinder dị iche. Mmanụ mmanụ na-agbapụta mmanụ na mmanụ oghere na-abanye n'ime oghere na-enweghị mkpanaka nke cylinder mmanụ n'otu oge, na-eme ka mkpanaka piston gbatịa ngwa ngwa; valvụ isi mmiri na-alaghachi, hapụ aka ahụ, na valvụ isi na-alaghachi na-akpaghị aka N'ọnọdụ na-anọpụ iche, mmegharị cylinder na-akwụsị.

B. Na-ebuli tong cylinder valvụ II: Na-achịkwa ihe na-ebuli tong II cylinder ka ịgbatị na retract ka ịtọpụ na ikesie ike arịlịka isi eriri. A na-edozi isi valve na ọnọdụ valvụ na-ese n'elu mmiri iji mepụta sekit cylinder dị iche. Mmanụ mmanụ na-agbapụta mmanụ na mmanụ oghere na-abanye n'ime oghere na-enweghị mkpanaka nke cylinder mmanụ n'otu oge, na-eme ka mkpanaka piston gbatịa ngwa ngwa; valvụ isi mmiri na-alaghachi, hapụ aka ahụ, na valvụ isi na-alaghachi na-akpaghị aka N'ọnọdụ na-anọpụ iche, mmegharị cylinder na-akwụsị.

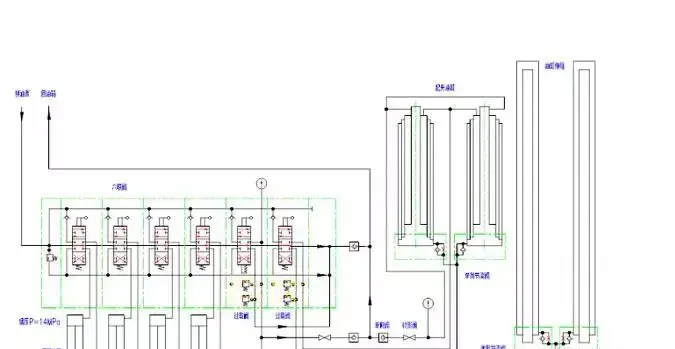

13) valvụ mmadụ isii: arụnyere na igbe njikwa hydraulac na azụ aka ekpe nke etiti ahụ. Ọ mejupụtara efere inlet dị ala, mmanụ mmanụ na-arụ ọrụ na efere isii na-arụ ọrụ. A na-ejikọ mmanụ dị na mmanụ dị na valve na-enwe ihe nchebe iji dozie nrụgide na-arụ ọrụ na-abanye valvụ isii. Nke a na-atọghe ma na-emechi akụ, ma na-agbagọ agbagha ka ịgbanwee nrụgide nke valvụ nchekwa. Mgbe ị na-emegharị, nrụgide na-abawanye ụba, ma mgbe ị na-ebelata, na-agbazi nrụgide. Rịba ama na mgbe mmezi, na-eme ka okpueze azụ ma kpochie ya.

- Ihu nri na-eme ihe ike: Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị.

- Vallder Cylinderger Cylinderger: na-ejikwa cylinder feelder nke dị n'ihu etiti ahụ, na-ewelite ma na-akwagide etiti ahụ. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị.

- Na azụ nri nri cylinderger cylinder: na-achịkwa ikike nri esi nri na azụ nke etiti ahụ. Bulie, ala na larịị. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị.

- Za azụ Gallinger valvle: na-achịkwa cylinder overderger na azụ nke etiti ahụ. Bulie, ala na larịị. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị.

- Ibulite valvụ Cylinder: na-achịkwa mmegharị nke cylinder na-ewelite ma belata derrill. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị. Ihe ọ na - emepụta mmanụ n'ọdụ mmanụ nwere nnukwu nchekwa iji belata nrụgide na - abanye cylinder mmanụ ma meziwanye nchekwa nke ọrụ Derrick.

- Telescopic mmanụ cylinder mmanụ: na-achịkwa ihe nke telescopic mmanụ cylinder mmanụ na-agbatị ma tụfuo akwụkwọ nke abụọ. A na-ewepụta Polla Core Pin mkpọchi ma tọhapụ ya. Corvụ valvụ ka nọgidere n'ọnọdụ ọrụ na cylinder mmanụ na-aga n'ihu na-aga. Ihe ọ na - emepụta mmanụ n'ọdụ mmanụ nwere nnukwu nchekwa iji belata nrụgide na - abanye cylinder mmanụ ma meziwanye nchekwa nke ọrụ Derrick.

13) valvụ mmadụ isii: arụnyere na igbe njikwa hydraulac na azụ aka ekpe nke etiti ahụ. Ọ mejupụtara efere inlet dị ala, mmanụ mmanụ na-arụ ọrụ na efere isii na-arụ ọrụ. A na-ejikọ mmanụ dị na mmanụ dị na valve na-enwe ihe nchebe iji dozie nrụgide na-arụ ọrụ na-abanye valvụ isii. Nke a na-atọghe ma na-emechi akụ, ma na-agbagọ agbagha ka ịgbanwee nrụgide nke valvụ nchekwa. Mgbe ị na-emegharị, nrụgide na-abawanye ụba, ma mgbe ị na-ebelata, na-agbazi nrụgide. Rịba ama na mgbe mmezi, na-eme ka okpueze azụ ma kpochie ya.

A. Froid Toilfulge Vallinger valvle: na-achịkwa ikike nri na-achasi ike n'ihu etiti ahụ, na-ewelite ma na-ebelata ọkwa ahụ. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị.

B. N'igwe aka ekpe nke Cylinderger gwọọ: na-achịkwa cylinder feredder na ihu nke etiti ahụ, na-ewelite ma na-ebelata ọkwa ahụ. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị.

C. Nzụlite aka nri nke Cylinger Cylinger Cylinder: na-achịkwa ikike nri esi nri na azụ nke etiti ahụ. Bulie, ala na larịị. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị.

D. Nkuku aka ekpe nke cylinderger cylinderger: na-ejikwa cylinder feelder na azụ nke etiti ahụ. Bulie, ala na larịị. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị.

E. Iwelite valvụ cylinder: na-achịkwa mmegharị nke cylinder na-ewelite ma belata derrill. Valvụ Corve Corring Returns ga-alaghachi, wepụta aka ahụ, valvụ na-akpaghị aka na-akpaghị aka na-akpaghị aka na nnọpụiche ahụ, yana ijegharị cylinder na-akwụsị. Ihe ọ na - emepụta mmanụ n'ọdụ mmanụ nwere nnukwu nchekwa iji belata nrụgide na - abanye cylinder mmanụ ma meziwanye nchekwa nke ọrụ Derrick.

F. Telescopic mmanụ cylinder mmanụ cylinder: na-eme ihe nke cylinder mmanụ nke telescopic na-agbatị ma weghachite akwụkwọ nke abụọ. A na-ewepụta Polla Core Pin mkpọchi ma tọhapụ ya. Corvụ valvụ ka nọgidere n'ọnọdụ ọrụ na cylinder mmanụ na-aga n'ihu na-aga. Ihe ọ na - emepụta mmanụ n'ọdụ mmanụ nwere nnukwu nchekwa iji belata nrụgide na - abanye cylinder mmanụ ma meziwanye nchekwa nke ọrụ Derrick.

2.steering hydraulic usoro

Mejupụtara ihe ndị a:

1) A na-etinye mmiri mgbapụta mmanụ na ike wepụ ọdụ ụgbọ mmiri nke injin ahụ. Injin ahụ na-atụgharị ma na-awụpụ mmanụ mgbapụta ahụ ịrụ ọrụ.

2) Mmanụ mmanụ nwere ihe owuwu nwere ihe owuwu na mpụga. A na-etinye ya n'akụkụ nke mmiri hydraulic mmanụ. A na-emikpu mmanụ a na-emighị emi n'okpuru mmiri mmiri dị na ite mmanụ. E kpughere isi nzacha na mpụga mmanụ mmanụ. A kwadebere ya na valvụ na-akara aka onwe ya, valvass vapass na ihe dị iche iche. Mgbe ị na-edochi ma ọ bụ nhicha ahụ nzacha nke ngwaọrụ dịka mmetọ na-agafe agafe, enwere ike ịme ya n'èzí. Ọ dị mfe ịkwasa ma wụnye, na mmanụ dị na tank ahụ agaghị abanye.

3) Overflow na-emejupụta valvụ na-agbaze usoro nrụgide, na-egbochi usoro oke, ma na-echebe nchekwa nke sistemu na ihe; Mpempe mmanụ mmanụ na-arụ ọrụ na oke ọsọ, yana ọnụego ọnụego buru ibu buru oke ibu, a na-atụgharịgharị na tank ahụ iji hụ na ọnụego sistemụ kachasị elu nke sistemụ ahụ. Lee eserese (enyemaka na mbido mmachi)

4) Valvụ na-esonye na-eso ntuziaka nke wiil ahụ, na-achịkwa nduzi na mmanụ hydraulic, na-enye ndị na-ahụ maka axle ka ọ ga-atụgharị aka ekpe na aka ekpe. Lee ọnụọgụ (steepụ nkesa nkesa)

5) Squainder steensing, ụzọ abụọ piston abụọ, otu maka axles ihu abụọ; A na-ejikọ isi Rodon na steepụ mkpịsị aka iji chịkwaa ogwe wiil. Lee foto (steenting cylinder)

- A na-ejikọ valvụ bọọlụ n'etiti nrụgide ọkpọ na ọkpọ mmanụ. Mgbe Riggg na-egwu mmiri na-arụ ọrụ, mepee valvụ bọọlụ iji budata sistemụ ma chebe usoro sistemụ.