Nau'o'in bawul mai kula da na'ura mai kwakwalwa

2024-03-22Ana amfani da bawul ɗin sarrafawa na hydraulic don sarrafa matsa lamba, gudana da tafiyar da mai a cikin tsarin hydraulic don matsawa, saurin gudu da motsi na mai kunnawa ya dace da bukatun. Dangane da ayyukansu, bawul ɗin sarrafa na'ura mai aiki da ruwa sun kasu kashi uku: bawul ɗin shugabanci, bawul ɗin matsa lamba da bawul ɗin kwarara.

Bawul mai sarrafawa ta hanya

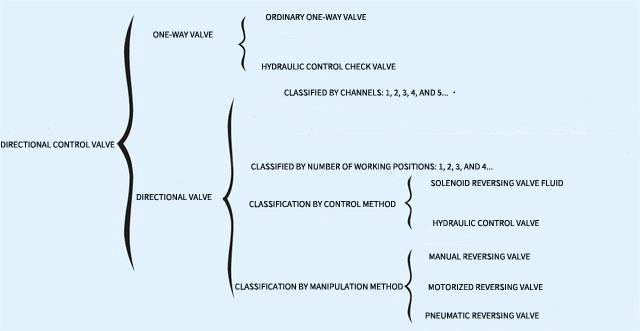

Hannun bawul ɗin bawul ne da ake amfani da shi don sarrafa alkiblar mai. An raba shi zuwa bawul mai hanya ɗaya da bawul ɗin juyawa bisa ga nau'in.

Nau'o'in bawul ɗin sarrafa jagora sune kamar haka:

(1) Bawul mai hanya ɗaya (check bawul)

Bawul ɗin hanya ɗaya shine bawul ɗin shugabanci wanda ke sarrafa kwararar mai a hanya ɗaya kuma baya barin juyawa baya. An raba shi zuwa nau'in bawul ɗin ball da nau'in bawul ɗin poppet bisa ga tsarin tushen bawul, kamar yadda aka nuna a hoto 8-17.

Hoto na 8-18(b) yana nuna bawul ɗin duba poppet. Halin asali na bawul shine cewa an danna maɓallin bawul ɗin da sauƙi a kan wurin zama a ƙarƙashin aikin bazara. A lokacin aiki, yayin da matsa lamba a matsi na man fetur P yana ƙaruwa, yana shawo kan matsi na bazara kuma yana ɗaga bawul core, yana haifar da bawul ɗin ya buɗe kuma ya haɗa da'irar mai, don haka mai ya shiga daga mashigar mai kuma yana fita daga tashar mai. Akasin haka, lokacin da matsin mai a gidan man ya fi karfin man fetur a mashigar mai, matsawar mai yana matsa mashin din bawul din sosai a kan kujerar bawul, yana toshe hanyar mai. Ayyukan bazara shine don taimakawa man da ke gudana ta hanyar hydraulically yana ƙarfafa tashar bawul lokacin da bawul ɗin ke rufe don ƙarfafa hatimi.

(2) Bawul na jagora

Ana amfani da bawul ɗin juyawa don canza hanyar kwararar mai don canza yanayin motsi na tsarin aiki. Yana amfani da maɓallin bawul don matsawa dangi zuwa jikin bawul don buɗewa ko rufe da'irar mai daidai, ta haka canza yanayin aiki na tsarin hydraulic. Lokacin da bawul core da bawul jiki suna a cikin dangi matsayi da aka nuna a cikin Hoto 8-19, da biyu da dakuna na na'ura mai aiki da karfin ruwa Silinda an katange daga matsa lamba man fetur kuma suna cikin wani yanayin rufewa. Idan an yi amfani da ƙarfi daga dama zuwa hagu zuwa ga ɗigon bawul don matsar da shi zuwa hagu, ana haɗa tashoshin man P da A akan bawul ɗin, kuma B da T suna haɗa. Man fetur yana shiga cikin ɗakin hagu na silinda mai ruwa ta hanyar P da A, kuma piston yana motsawa zuwa dama; Man da ke cikin rami yana komawa zuwa tankin mai ta hanyar B da T.

Akasin haka, idan aka yi amfani da karfi daga hagu zuwa dama a kan bawul core don matsar da shi zuwa dama, to, an haɗa P da B, ana haɗa A da T, kuma piston yana motsawa zuwa hagu.

Dangane da nau'ikan motsi daban-daban na tushen bawul, bawul ɗin jujjuya za'a iya kasu kashi biyu: nau'in bawul ɗin faifai da nau'in bawul ɗin rotary. Daga cikin su, ana amfani da bawul ɗin juyawa na nau'in faifai. Ana rarraba bawul ɗin zamewa bisa ga adadin wuraren aiki na ɗigon bawul a cikin jikin bawul da tashar tashar mai da ke sarrafa bawul ɗin juyawa. Bawul ɗin juyawa yana da matsayi biyu-biyu-biyu, biyu-matsayi uku-hanyar, biyu-hudu-hanyar, biyu-biyar-biyar-hanyar da sauran iri. , duba Table 8-4. Lambobin matsayi daban-daban da wucewa suna haifar da nau'i-nau'i daban-daban na raƙuman da aka yanke a kan jikin bawul da kuma kafadu a kan maɓallin valve.

Dangane da hanyar sarrafa spool, bawul ɗin jagora sun haɗa da na'urar hannu, injin motsa jiki, lantarki, na'ura mai ƙarfi da nau'ikan lantarki-hydraulic.

Bawul ɗin matsi

Ana amfani da bawul ɗin matsa lamba don sarrafa matsa lamba na tsarin ruwa, ko amfani da canje-canje a cikin matsa lamba a cikin tsarin don sarrafa aikin wasu abubuwan haɗin ruwa. Dangane da amfani daban-daban, ana rarraba bawul ɗin matsa lamba zuwa bawul ɗin taimako, matsa lamba rage bawul, bawuloli na jerin da kuma relays matsa lamba.

(1) Bawul ɗin taimako

Bawul ɗin ambaliya yana kula da matsa lamba mai yawa a cikin tsarin sarrafawa ko kewayawa ta hanyar ambaliya ta tashar bawul, don haka cimma ayyukan daidaitawar matsa lamba, ƙayyadaddun matsa lamba ko ƙayyadaddun matsa lamba. Bisa ga ka'idar tsarinsa, ana iya raba shi zuwa nau'i biyu: nau'in aiki kai tsaye da nau'in matukin jirgi.

(2) Wuraren Kula da Matsi

Ana iya amfani da bawul ɗin rage matsin lamba don ragewa da daidaita matsa lamba, rage mafi girman matsa lamba mai mai zuwa ƙarami da kwanciyar hankali matsa lamba mai.

Ka'idar aiki na ƙwanƙwasa mai rage matsa lamba shine dogara ga man fetur mai matsa lamba don rage matsa lamba ta hanyar rata (juriya na ruwa), don haka matsa lamba ya fi ƙasa da matsa lamba, kuma matsa lamba yana kiyayewa a wani ƙimar. Ƙananan rata, mafi girman asarar matsa lamba, kuma mafi karfi tasirin rage matsa lamba.

Ka'idodin tsari da alamomin matsi na rage bawuloli masu sarrafa matukin jirgi. Man mai matsa lamba tare da matsa lamba na p1 yana gudana daga mashigar mai A na bawul. Bayan ƙaddamarwa ta hanyar rata δ, matsa lamba ya sauko zuwa p2, sa'an nan kuma ya fita daga man fetur B. Lokacin da matsa lamba p2 ya fi girma fiye da matsa lamba na daidaitawa, ana tura bawul ɗin poppet bude, kuma wani ɓangare na matsa lamba a cikin ɗakin mai a gefen dama na babban bawul ɗin zamewa yana gudana cikin tankin mai ta hanyar buɗaɗɗen bawul ɗin poppet da ramin Y na ramin magudanar ruwa. Saboda tasirin ƙaramin ramin damping R a cikin babban madaidaicin faifan faifan, matsa lamba mai a cikin ɗakin mai a daidai ƙarshen bawul ɗin zamewa yana raguwa, kuma maɓallin bawul ɗin ya rasa daidaituwa kuma yana motsawa zuwa dama. Sabili da haka, rata δ yana raguwa, tasirin raguwa yana ƙaruwa, kuma matsa lamba p2 yana raguwa. zuwa ƙimar da aka daidaita. Hakanan za'a iya daidaita wannan ƙimar ta hanyar matsi mai daidaita matsi.

Matsin aiki kai tsaye yana rage bawul

(3) Wuraren Kula da Guda

Ana amfani da bawul ɗin ruwa don sarrafa kwararar ruwa a cikin tsarin hydraulic don cimma nasarar sarrafa saurin tsarin tsarin ruwa. Bawuloli masu gudana da aka saba amfani da su sun haɗa da bawul ɗin magudanar ruwa da bawuloli masu daidaita saurin gudu.

Bawul ɗin da ke gudana shine sashin daidaita saurin gudu a cikin tsarin injin ruwa. Ka'idar sarrafa saurinsa ta dogara ne akan canza girman yanki mai gudana na tashar bawul ko tsayin tashar kwarara don canza juriya na ruwa, sarrafa kwarara ta cikin bawul, da daidaita mai kunnawa (Silinda ko mota). ) manufar saurin motsi.

1) Bawul din magudanar ruwa

Siffofin da aka saba amfani da su na bawul ɗin maƙura na yau da kullun ana nuna su a cikin adadi, gami da nau'in bawul ɗin allura, nau'in eccentric, nau'in tsagi na axial triangular, da sauransu.

Bawul ɗin ma'auni na yau da kullun yana ɗaukar nau'in tsagi na axial triangular mai buɗewa. A lokacin aiki, maɓallin bawul ɗin yana da ƙarfi sosai, yana da kwanciyar hankali mai kyau kuma ba shi da sauƙin toshewa. Man mai matsa lamba yana gudana daga mashigin mai p1, ya shiga cikin rami a ta ramin b da tsagi mai matsewa a gefen hagu na bawul core 1, sannan ya fito daga mashin mai p2. Lokacin daidaita magudanar ruwa, juya matsi mai daidaita kwaya 3 don matsar da sandar turawa 2 tare da axial direction. Lokacin da sandar turawa ta motsa zuwa hagu, maɓallin bawul ɗin yana motsawa zuwa dama a ƙarƙashin aikin ƙarfin bazara. A wannan lokacin, ma'auni yana buɗewa da faɗi kuma yawan kwarara yana ƙaruwa. Lokacin da man ya wuce ta hanyar magudanar ruwa, za a sami asarar matsa lamba △p=p1-p2, wanda zai canza tare da kaya, yana haifar da canje-canje a cikin adadin magudanar ruwa ta tashar jiragen ruwa kuma yana shafar saurin sarrafawa. Sau da yawa ana amfani da bawul ɗin magudanar ruwa a cikin tsarin na'ura mai aiki da karfin ruwa inda nauyi da canje-canjen zafin jiki ƙanana ne ko buƙatun kwanciyar hankali na sauri sun yi ƙasa.

2) Bawul mai sarrafa saurin gudu

Bawul ɗin da ke sarrafa saurin yana ƙunshi ƙayyadadden matsi na rage bawul da bawul ɗin magudanar da aka haɗa cikin jeri. Matsakaicin bambance-bambancen matsa lamba na rage bawul na iya ta atomatik kula da bambance-bambancen matsa lamba kafin da bayan bawul ɗin maƙura ba a canza ba, don haka bambancin matsa lamba kafin da bayan bawul ɗin maƙura ba ya shafa ta kaya, ta haka yana wucewa ta bawul ɗin magudanar ruwa Ainihin ƙayyadaddun ƙayyadaddun ƙayyadaddun ba ne. darajar.

Matsakaicin rage bawul 1 da magudanar magudanar ruwa 2 an haɗa su a cikin jeri tsakanin famfo na hydraulic da silinda na hydraulic. Man fetur mai matsa lamba daga famfon na'ura mai aiki da karfin ruwa (matsa lamba shine pp), bayan an rage shi ta hanyar ratar buɗewa a matsin lamba yana rage tsagi a, yana gudana cikin tsagi b, kuma matsa lamba ya faɗi zuwa p1. Sa'an nan, yana gudana a cikin silinda na'ura mai aiki da karfin ruwa ta hanyar bawul ɗin ma'auni, kuma matsa lamba ya faɗi zuwa p2. A karkashin wannan matsa lamba, piston yana motsawa zuwa dama akan nauyin F. Idan nauyin ba shi da kwanciyar hankali, lokacin da F ya karu, p2 kuma zai karu, kuma bawul core na matsa lamba rage bawul zai rasa daidaito kuma ya matsa zuwa dama, haifar da bude rata a ramin a don ƙarawa, tasirin lalata zai raunana, kuma p1 kuma zai ƙara. Sabili da haka, bambancin matsa lamba Δp = pl-p2 ya kasance baya canzawa, kuma yawan kwararar da ke shiga cikin silinda na hydraulic ta hanyar bawul ɗin maƙura shima ya kasance baya canzawa. Akasin haka, lokacin da F ya ragu, p2 kuma yana raguwa, kuma maɓallin bawul na matsi na rage bawul zai rasa ma'auni kuma ya matsa zuwa hagu, don haka ratawar buɗewa a ramin yana raguwa, tasirin lalata yana haɓaka, kuma p1 kuma yana raguwa. , don haka bambancin matsa lamba △p = p1-p2 ya kasance baya canzawa, kuma yawan kwararar da ke shiga cikin silinda na ruwa ta hanyar bawul ɗin maƙura shima ya kasance baya canzawa.